Open hole packer tester and using method thereof

A test device and packer technology, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of complicated operation and high cost, and achieve simple device structure and reduce test time. Cost, effectiveness of reducing trial risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

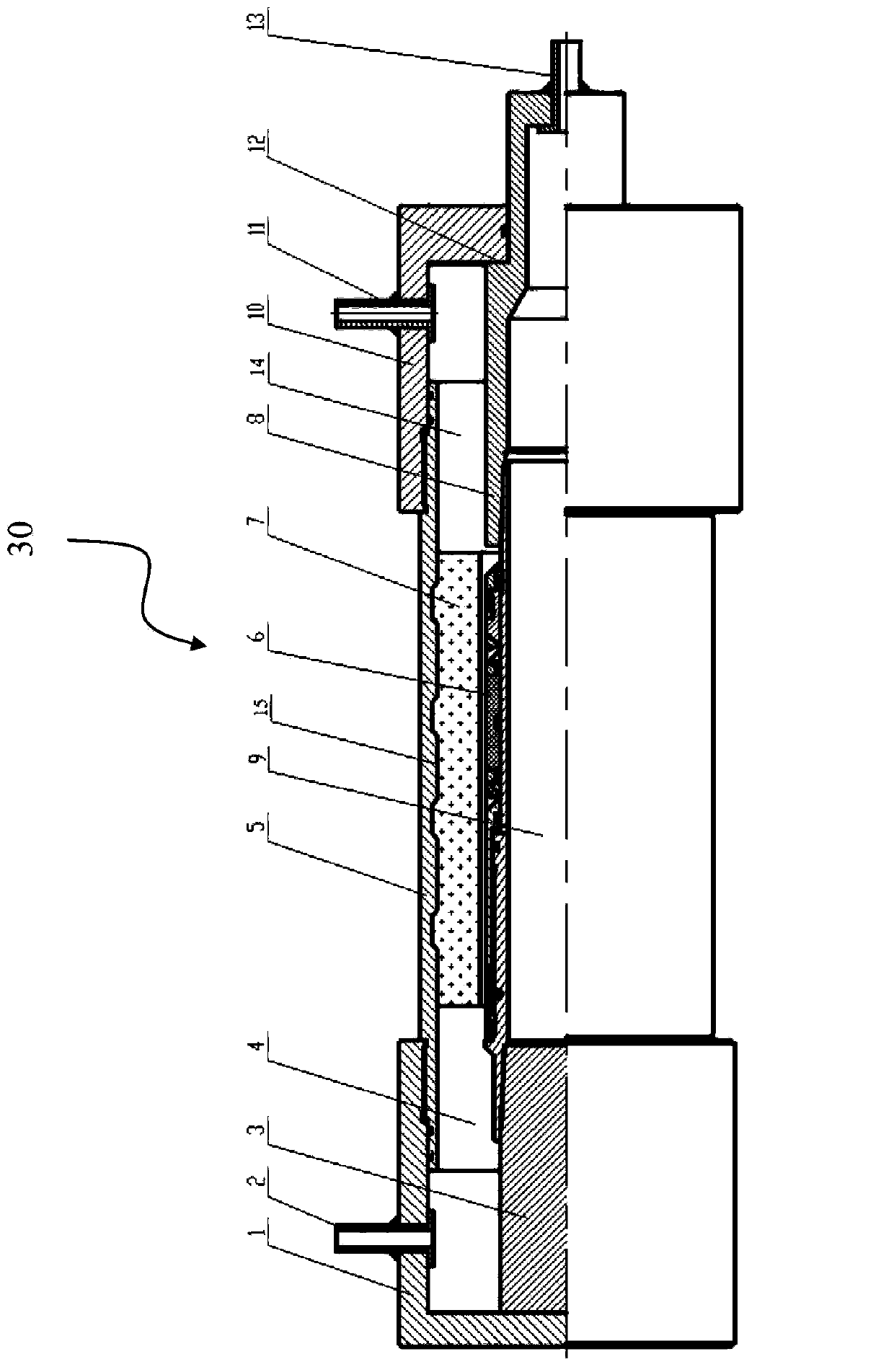

[0024] figure 1 An open hole packer test rig 30 according to the present invention is schematically shown. The open-hole packer test device 30 includes a casing 5 , an open-hole packer 6 is arranged inside the casing 5 , and a simulated wellbore 7 is arranged in a gap between the casing 5 and the open-hole packer 6 . A first wellbore head 1 and a second wellbore head 10 are respectively arranged at two ends of the casing 5 to seal the inside of the casing 5 . The two ends of the open hole packer 6 are respectively provided with open hole packer heads, such as figure 1 The first open hole packer head 3 and the second open hole packer head 8. The open hole packer heads 3 , 8 are in sealing contact with the corresponding wellbore heads 1 , 10 , thereby forming the first annulus 4 and the second annulus 14 . The structure of the open hole packer 6 is well known to those ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com