Embedment type 90-degree bent inserted PCB connector

A PCB connector and bend insertion technology, which is applied in the connection, the parts of the connection device, the electrical components, etc., can solve the problems of the difficulty of stripping the insulation of the wire connection, the large welding workload, and the loose wire at the end of the wire. Achieve the effect of eliminating wire loose wire, solving air bubbles or voids, and simplifying assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

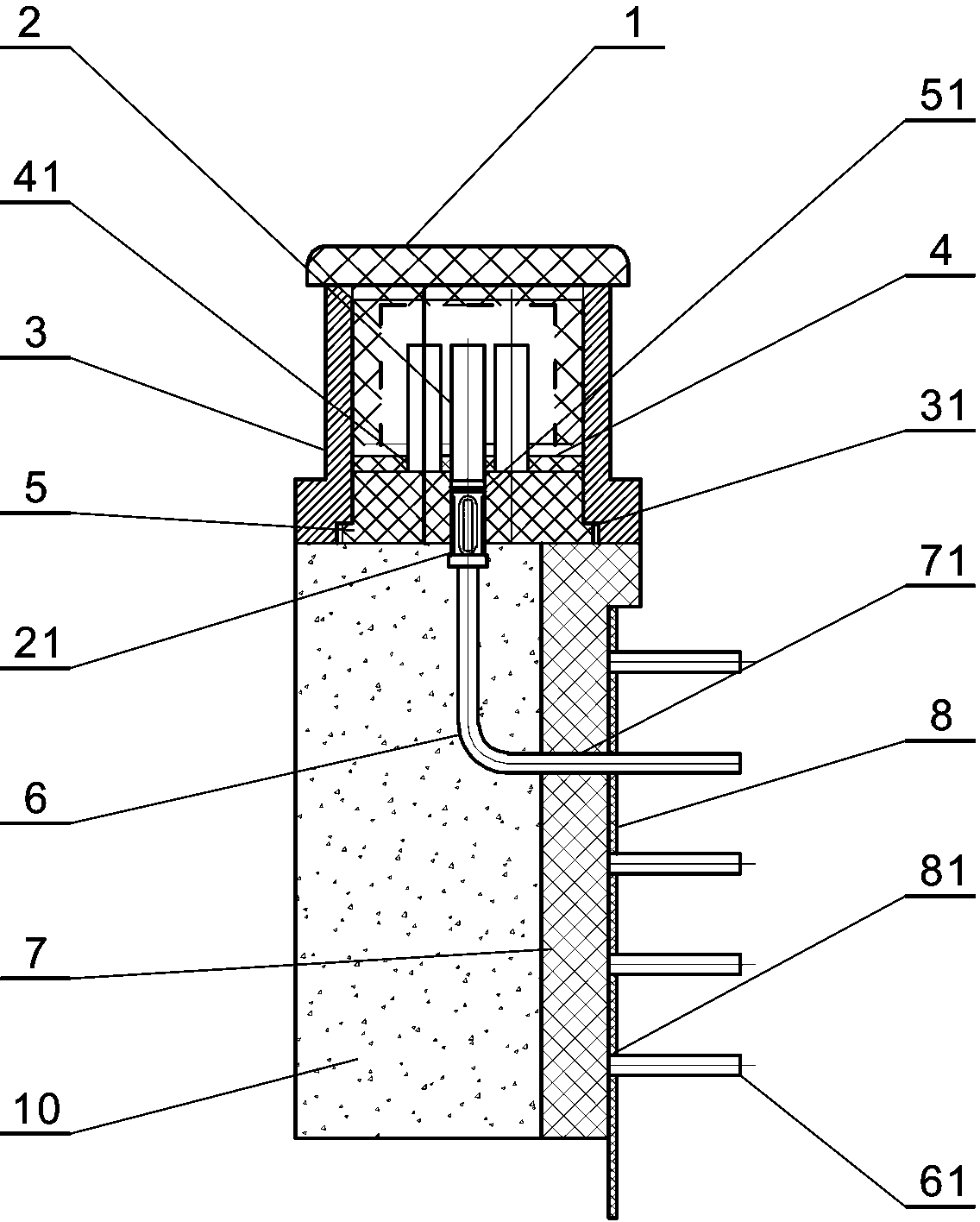

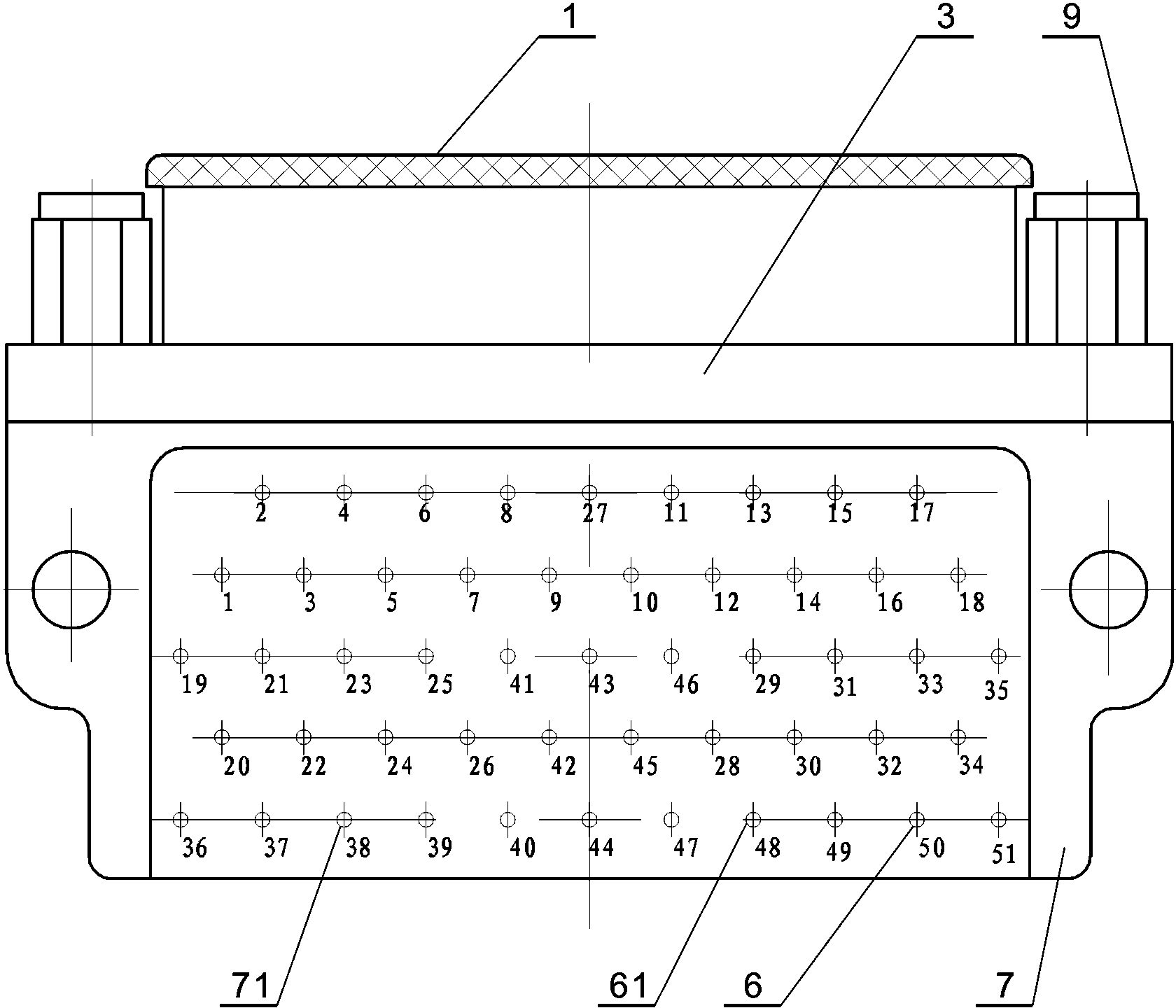

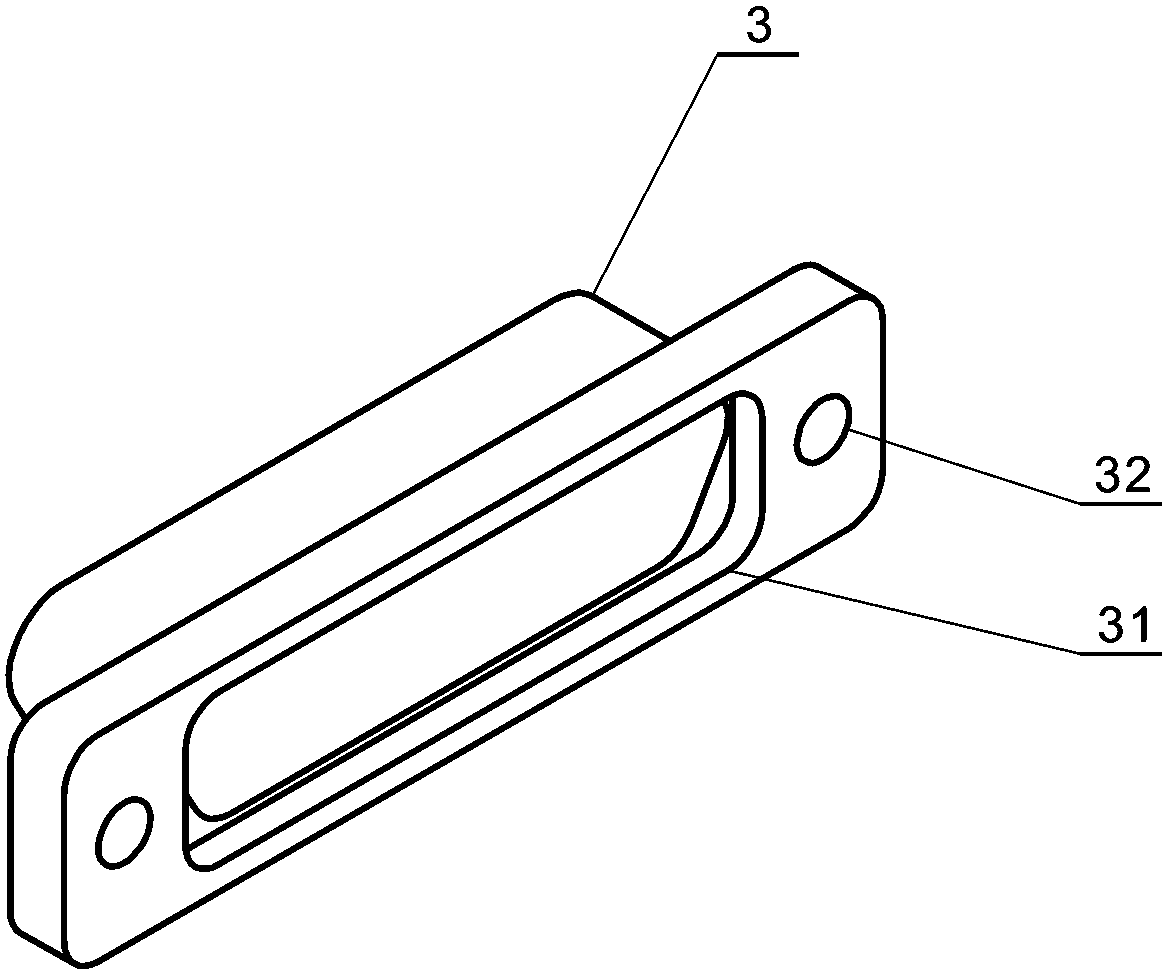

[0013] see Figure 1 to Figure 5 , the present invention includes a potting type 90° bend-inserted PCB connector, which is characterized in that it includes an electrostatic dust cover 1, a contact piece 2, a shell 3, a rubber pad 4, a base 5, an enameled wire 6, and a tail cover assembly. 7. Gasket 8, mounting screw 9 and potting glue 10, the casing 3 is a box body, its top surface is provided with a base pool 31, two sides are provided with screw holes 32, and one end of the contact piece 2 is provided with a crimp The cylinder 21, the base 5 is provided with a number of contact holes 51, the tail cover assembly 7 is a plate with blocks on both sides, the board is provided with a number of pin holes 71, and the blocks are provided with threaded holes 72. The enameled wire 6 is bent into an "L" shape, the rubber pad 4 is provided with a through hole corresponding to the contact hole 51 of the base 5, the rubber pad 4 is arranged in the housing 3, and the through hole of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com