In-furnace handling device and heating furnace

A technology of a handling device and a heating furnace, which is applied in the field of heating furnaces, can solve the problems of increased water cooling loss, large water cooling equipment, etc., and achieves the effects of reducing the excavation depth, reducing the operating cost and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, an in-furnace conveying device and a heating furnace provided with the in-furnace conveying device according to an embodiment of the present invention will be specifically described with reference to the drawings. In addition, the in-furnace conveyance apparatus and heating furnace of this invention are not limited to the in-furnace conveyance apparatus and heating furnace shown in the following embodiment, It can change suitably within the range which does not change the inventive idea, and can implement.

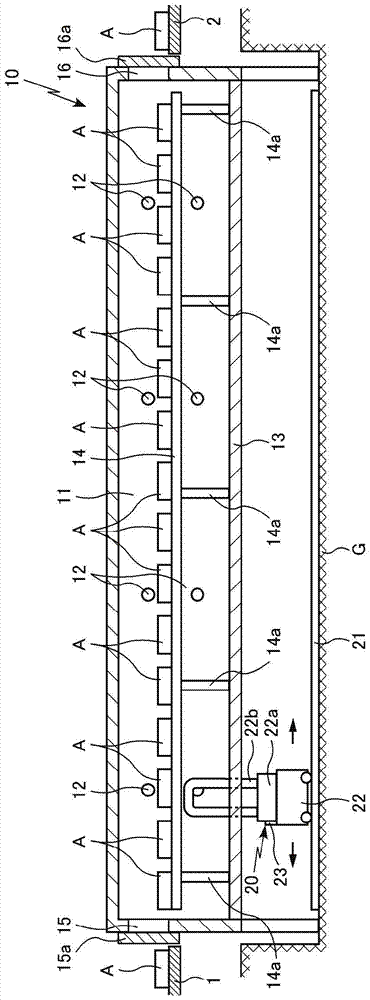

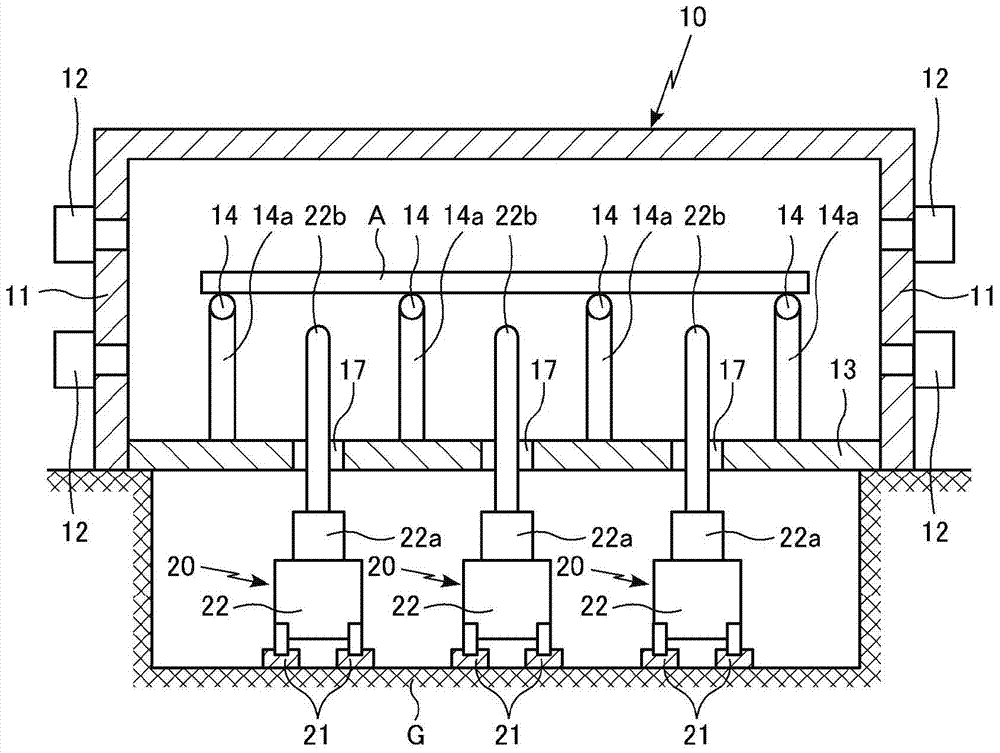

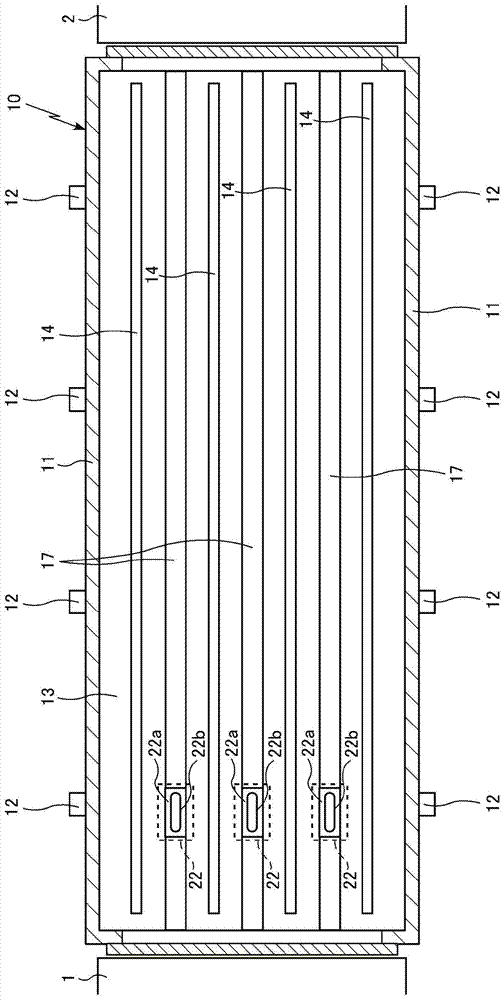

[0046] In the heating furnace 10 of the present embodiment, as Figure 1 ~ Figure 3 As shown, a plurality of combustion devices 12 are provided on its side wall 11, and support members 14a are erected on the hearth 13 of the heating furnace 10 at a required interval in the conveying direction of the object A to be processed. The member 14a is provided with a fixed beam 14 along the conveying direction of the processed object A, so that a plurality of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com