Method used for cleaning surfaces of castings, surfaces of pouring gates and surfaces of dead heads

A technology for surface cleaning and castings, which is applied in the field of surface cleaning of castings, runners and risers, and can solve problems that affect the efficient operation of the production process and limited weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

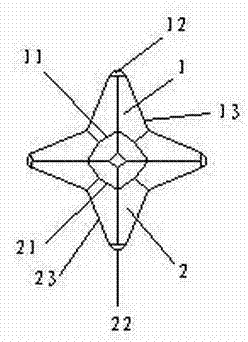

[0027] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing and embodiment:

[0028] This embodiment is used for the method for cleaning the surface of castings, runners and risers, and is used for cleaning the surface area sand of castings, runners and risers in the pouring machine drum. The method is: place the castings, runners and risers that need to be cleaned. The cleaning block is placed in the pouring machine drum of the riser, so that the cleaning block and the castings, runners and risers in the pouring machine drum roll together with the pouring machine drum, and the cleaning block keeps on the surface of the castings, runners and risers Friction is carried out, thereby cleaning the sand on the surface of castings, runners and risers, so as to achieve the purpose of cleaning the surfaces of castings, runners and risers.

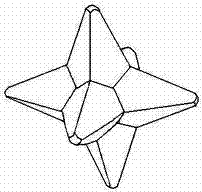

[0029] The cleaning block is made of wear-resistant material, and the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com