A system to prevent polishing pads from scratching wafers

A technology for polishing pads and wafers, which is applied to polishing devices, grinding machine tools, electrical components, etc., can solve problems such as ineffectiveness and ineffectiveness, and achieve the effect of reducing costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention provides a method for preventing chemical mechanical grinding macroscopic scratches, which can be applied to processes with technical nodes of 90nm, 65 / 55nm, 45 / 40nm, 32 / 28nm, greater than or equal to 130nm and less than or equal to 22nm; it can be applied to the following In the technology platform: Logic, Memory, RF, HV, Analog / Power, MEMS, CIS, Flash, eFlash and Package.

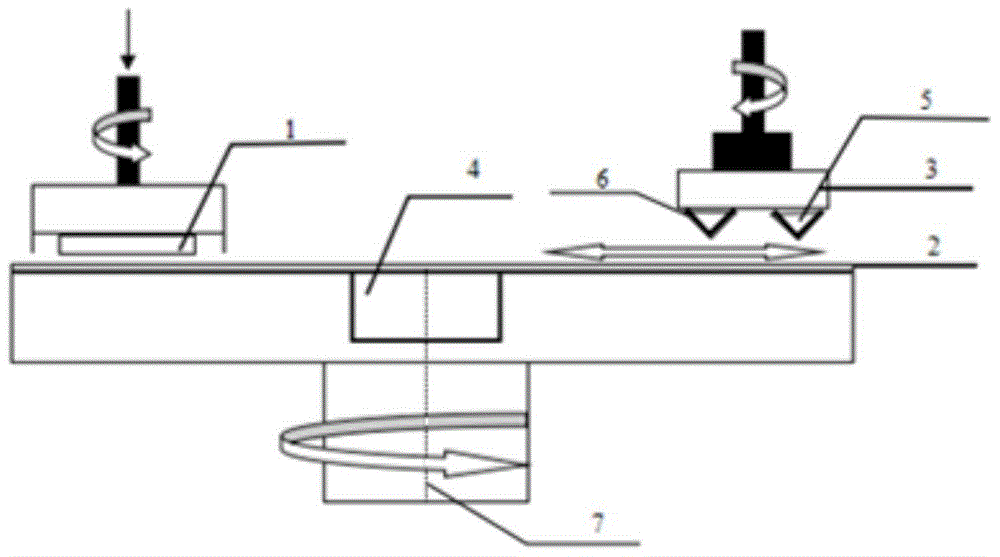

[0026] Such as Figure 1-3 Shown, a system for preventing polishing pads from scratching wafers, the system includes:

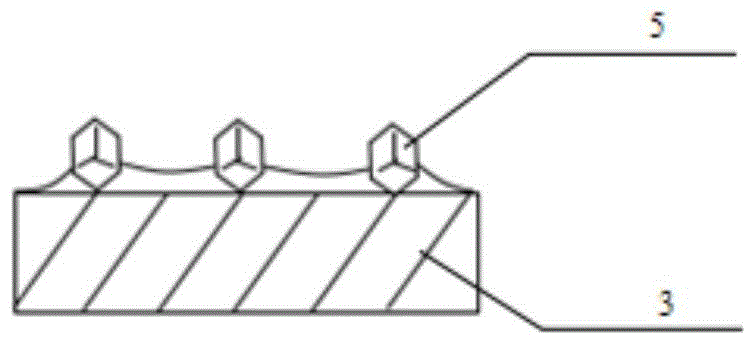

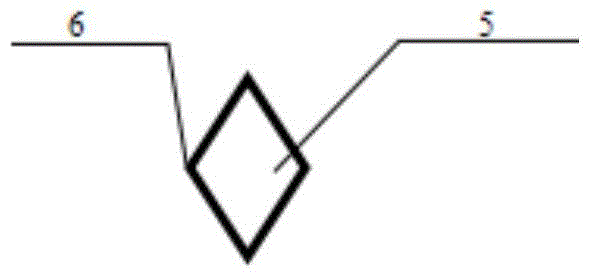

[0027] A cleaning disc, the surface of which is provided with a plurality of protruding diamonds, and each exposed surface of the diamonds is covered with a layer of magnetic material;

[0028] A grinding pad, the surface of which is set opposite to the surface of the cleaning disc;

[0029] A magnetic sensor, arranged below the polishing pad, to detect the magnetic condition on the surface of the polishing pad;

[0030] Wherein, during the chemical mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com