Online repairing device and method for inner wall of circular hole

A round hole, to-be-repaired technology, applied in the field of component repair, can solve problems such as difficulty in hoisting, long time for dismantling parts to be repaired, long cycle, etc., to reduce equipment downtime, avoid equipment deterioration, and improve repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

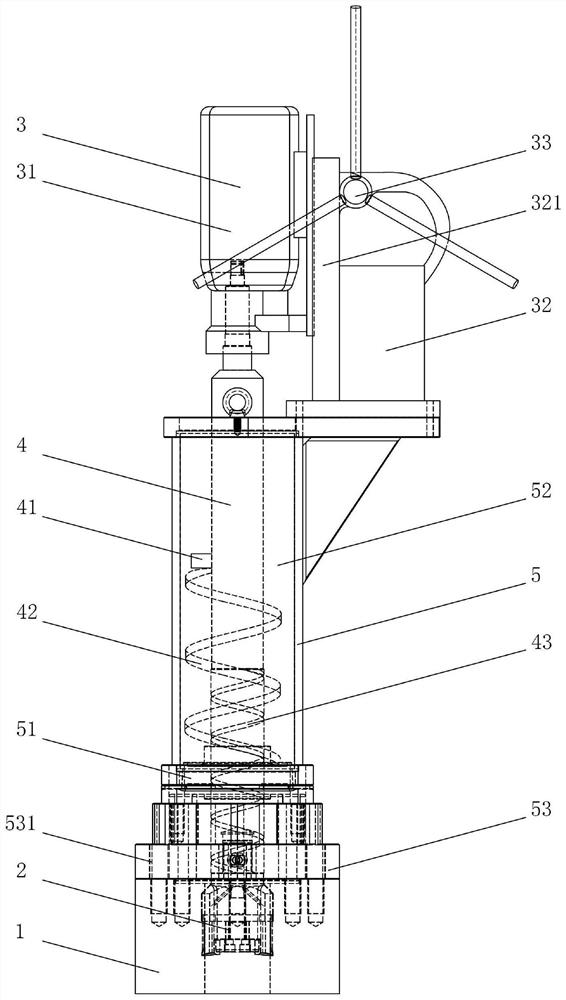

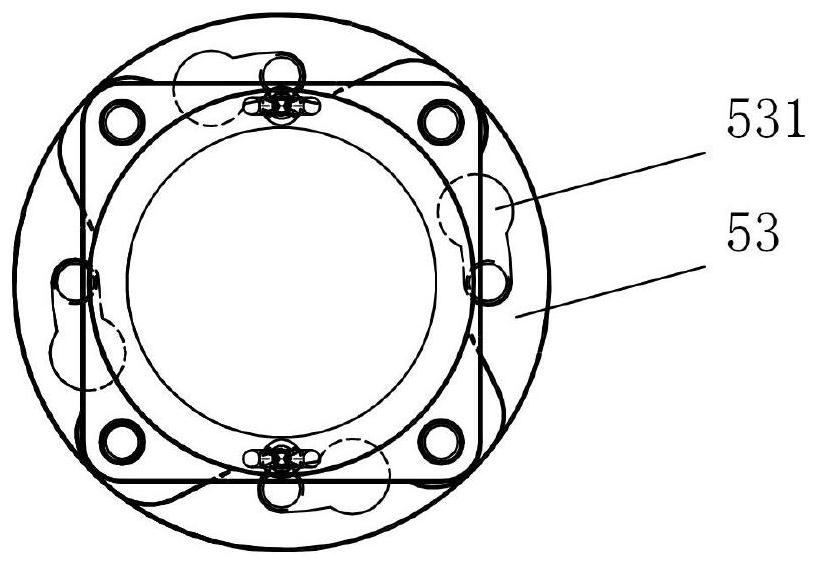

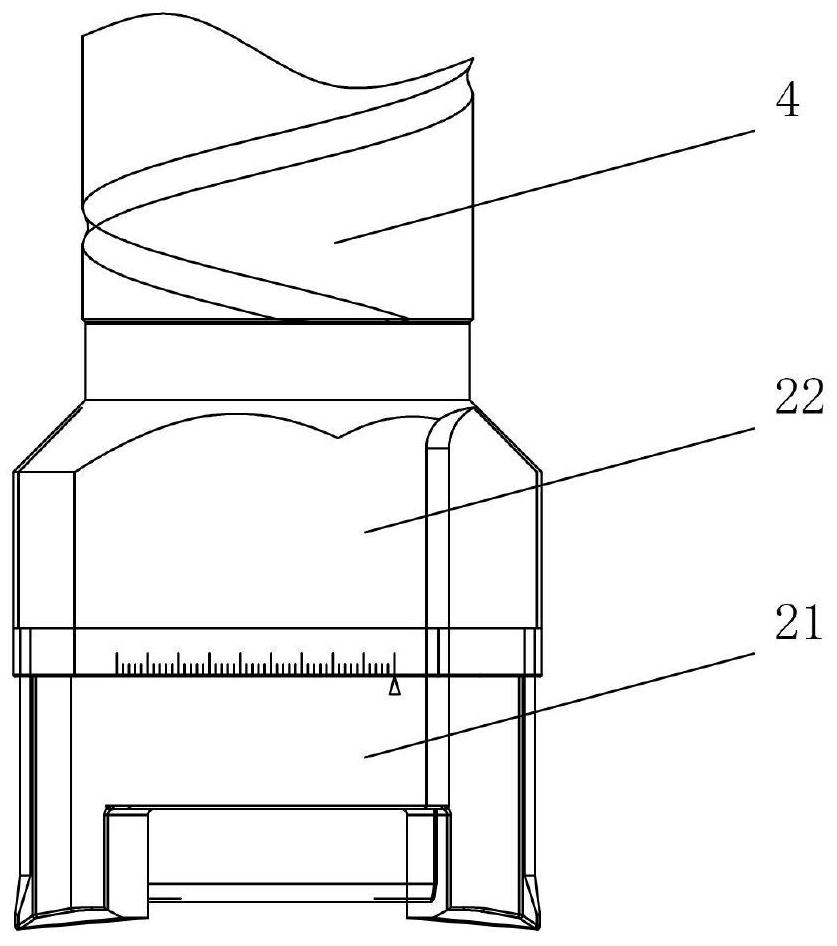

[0034] Such as figure 1 and figure 2 As shown, the online repair device for the inner wall of the hole in this embodiment is connected to the hole part 1 to be repaired, and includes a cutter body 2 that can be stretched into the hole of the hole part 1, and the cutter body 2 is around the axis of the hole. Rotate and repair the inner wall of the circular hole of the hole part 1 by cutting.

[0035] When the hole part 1 of the large-scale equipment is damaged due to operations such as disassembly and wear of peripheral connected equipment, the online repair device of this embodiment can be directly connected to the hole part 1 to be repaired, so there is no need to remove the hole part 1 from the large-scale equipment. It can also be repaired by demolition or demolition, so even pressure vessels can be repaired by this online repair device. At the same time, this online repair device can complete the repair on the spot, in a timely manner, and online at the location of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com