An automatic detection device for the glue head of a frame gluing machine

A technology of automatic detection device and gluing machine, which is applied to the device and coating of the surface coating liquid, can solve the problem of automatic equipment that has not yet appeared to detect the glue head of the frame gluing machine, increase the labor intensity of the staff, and increase the batch size. Problems such as poor quality of components can eliminate hidden troubles, reduce labor intensity and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

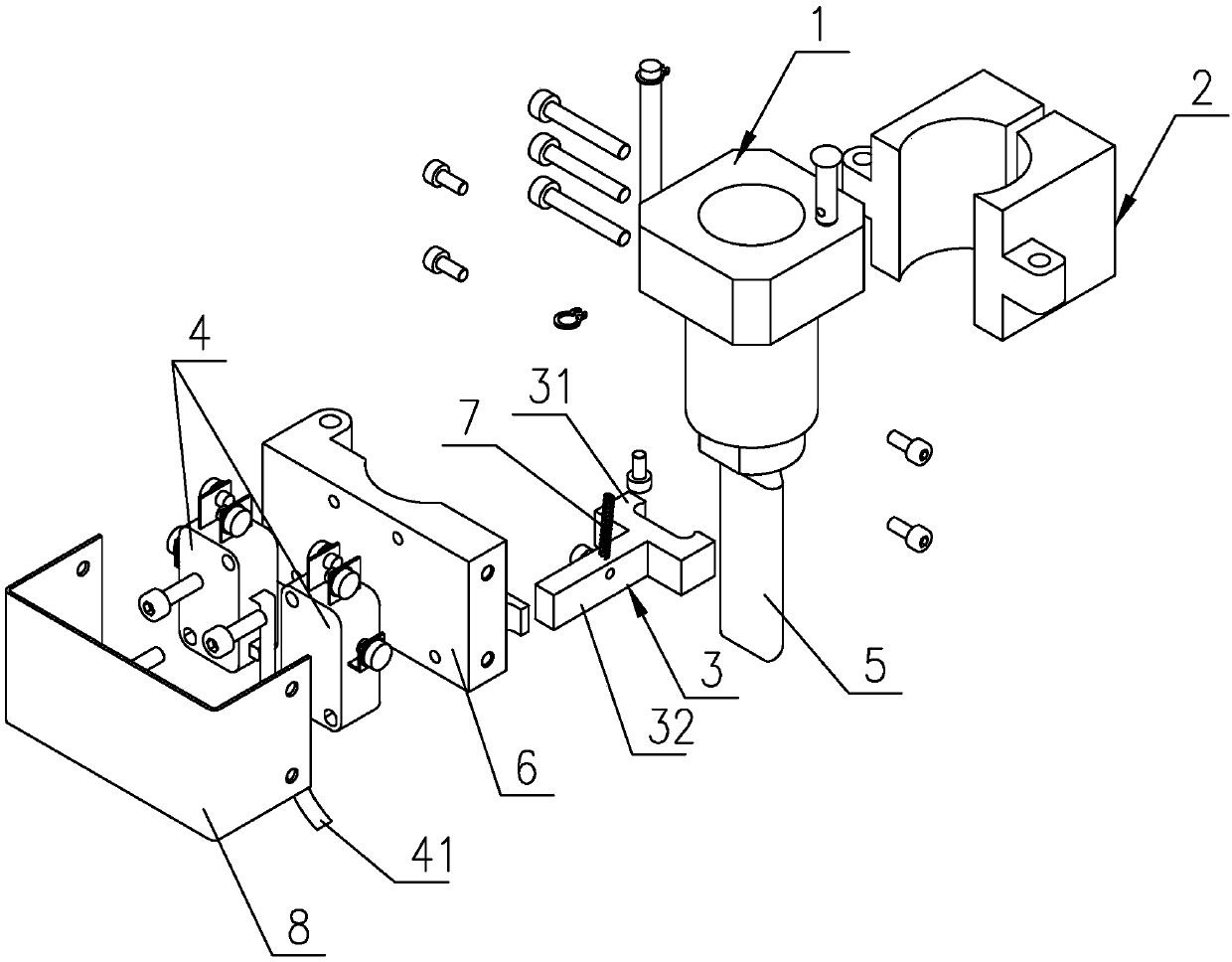

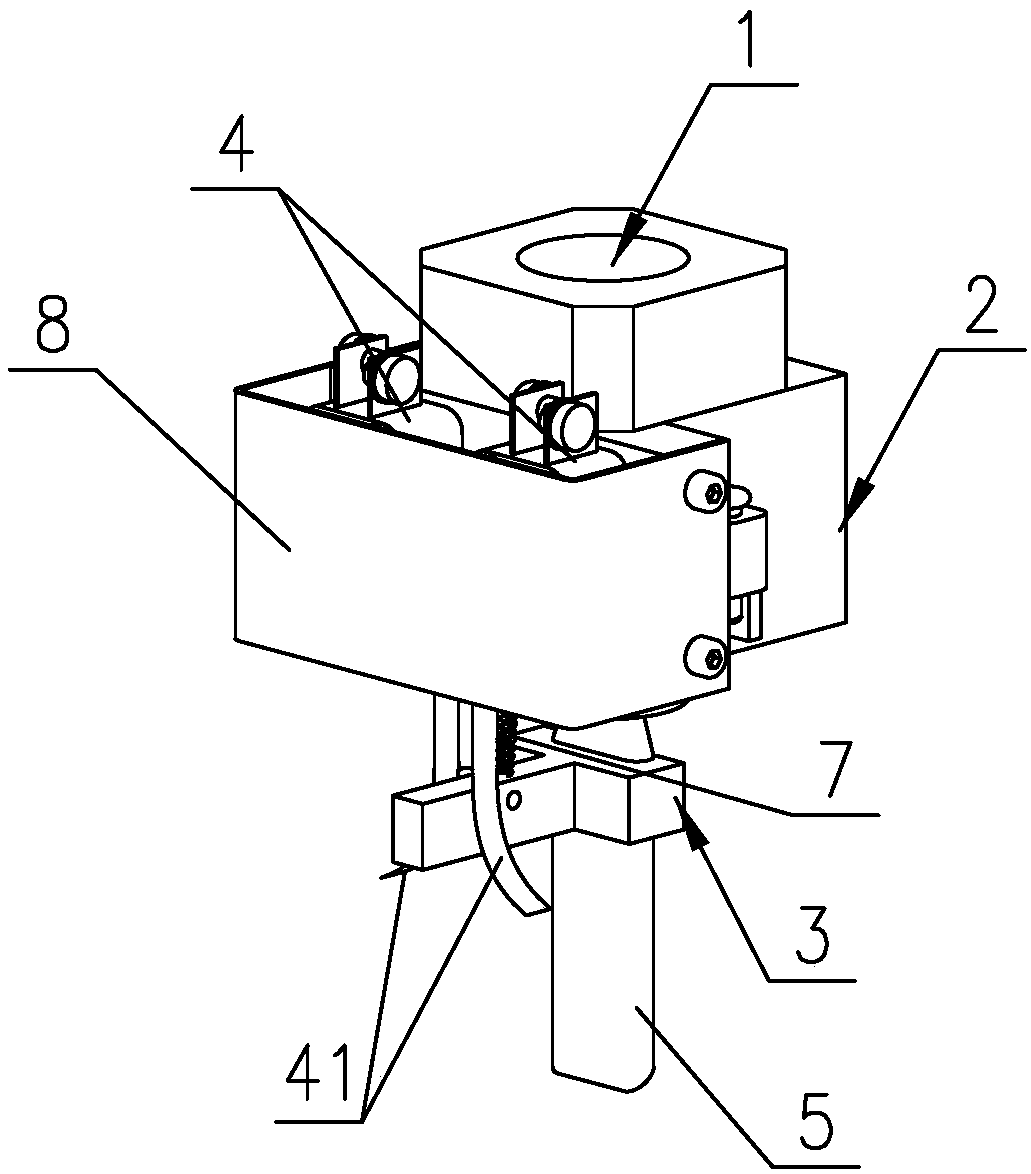

[0026] Such as figure 1 and 2 As shown, it is an automatic detection device for the glue head of the frame glue machine of the present invention, which includes a ferrule 2 for being installed on the glue valve 1 of the frame glue machine, a linkage rod 3 and a pair of parallel microswitches 4 , the pair of microswitches 4 are installed on the outer wall of the ferrule 2, each microswitch 4 has a driving rod 41 protruding downward, and the two driving rods 41 are symmetrically arranged side by side with a gap between them, the microswitch 4. Connect with the controller of the frame glue machine. The linkage rod 3 is arranged horizontally and under the ferrule 2. The linkage rod 3 is composed of a chuck 31 with a slot and a rod 32 connected to the chuck 31 at one end. , the card slot of the chuck 31 is engaged on the rubber head 5 of the frame gluer, and the other end of the rod 32 extends into the gap between the driving rods 41 of the pair of micro switches 4 and sticks clos...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the specific structure of the micro switch installed on the outer wall of the main body is different, that is, a pair of positioning rods are arranged side by side on the upper part of the outer wall of the main body, and the pair of micro switches have a positioning rod respectively. hole, the positioning rod correspondingly penetrates into the positioning hole, a block is provided on the lower part of the outer wall of the main body, a groove is provided between the pair of micro switches, the block is engaged in the groove, and the distance between the main body and the pair of micro switches One end of the limit spring is fixed on the outer wall of the main body, the other end is fixed on the micro switch, and the limit spring is vertically arranged. It is mainly composed of the first section, the horizontal section, the oblique section connected in sequence The first section is perpendicular to the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com