Quartz cutter handle

A knife handle and quartz technology, applied in the field of kitchen utensils, can solve the problems of complicated manufacturing process, unhealthy, easy to adhere to oil dirt, etc., and achieve the effect of stable chemical performance, simple structure, and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

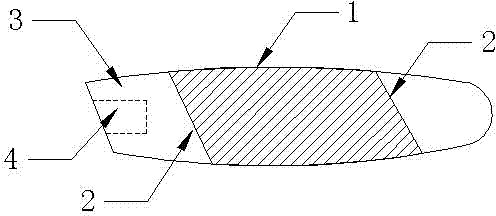

[0017] figure 1 It is a schematic structural diagram of a quartz knife holder provided by Embodiment 1 of the present invention. This embodiment includes a knife handle body 1 mainly made of fused silica blocks. The knife handle body 1 is formed by bonding three fused silica blocks of different colors, and crystal glue is provided between adjacent two fused silica blocks. Layer 2, the front end of the handle body 1 is provided with a blade connecting portion 3, and the blade connecting portion 3 is provided with a groove 4 for connecting the blade, and the curved surface of the holding part of the handle body 1 is set to match the shape of the human hand .

[0018] This specific embodiment has the advantages of simple structure, health and environmental protection, beautiful appearance and practicality, can be used as the handle of most knives, and is suitable for wide popularization and application.

Embodiment 2

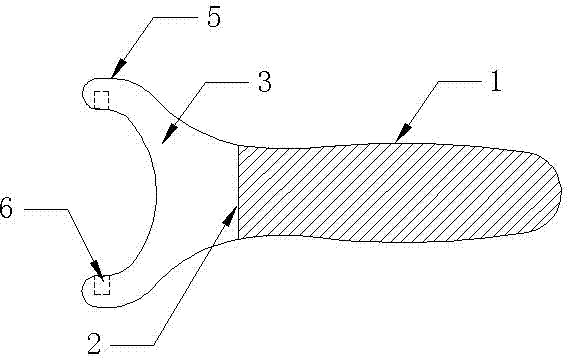

[0020] figure 2 It is a schematic diagram of the structure of the quartz knife handle provided by the second embodiment of the present invention. This embodiment includes a knife handle body 1 mainly made of fused silica blocks. The knife handle body 1 is formed by bonding two fused silica blocks of different colors, and a crystal glue is provided between adjacent two fused silica blocks. Layer 2, the front end of the handle body 1 is provided with a blade connecting part 3, and both sides of the blade connecting part 3 are provided with a symmetrical blade bracket 5, and the inner side of the blade bracket 5 is provided with a blade mounting hole 6, and the curved surface of the holding part of the knife handle body 1 It is set to a curved surface that matches the shape of the human hand.

[0021] This specific embodiment has the advantages of simple structure, health and environmental protection, beautiful appearance and practicality, can be used as a handle of a plane amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com