Preparation method of high-speed train carbon/ceramic composite material friction couple

A ceramic composite material, friction dual technology, applied in the direction of friction linings, brake discs, mechanical equipment, etc., can solve the requirements of the performance difference between high-speed train brake discs and brake pads, poor friction and wear performance, shorten the dual parts life and other issues, to improve stability and service life, reduce weight, and solve the effect of high temperature bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

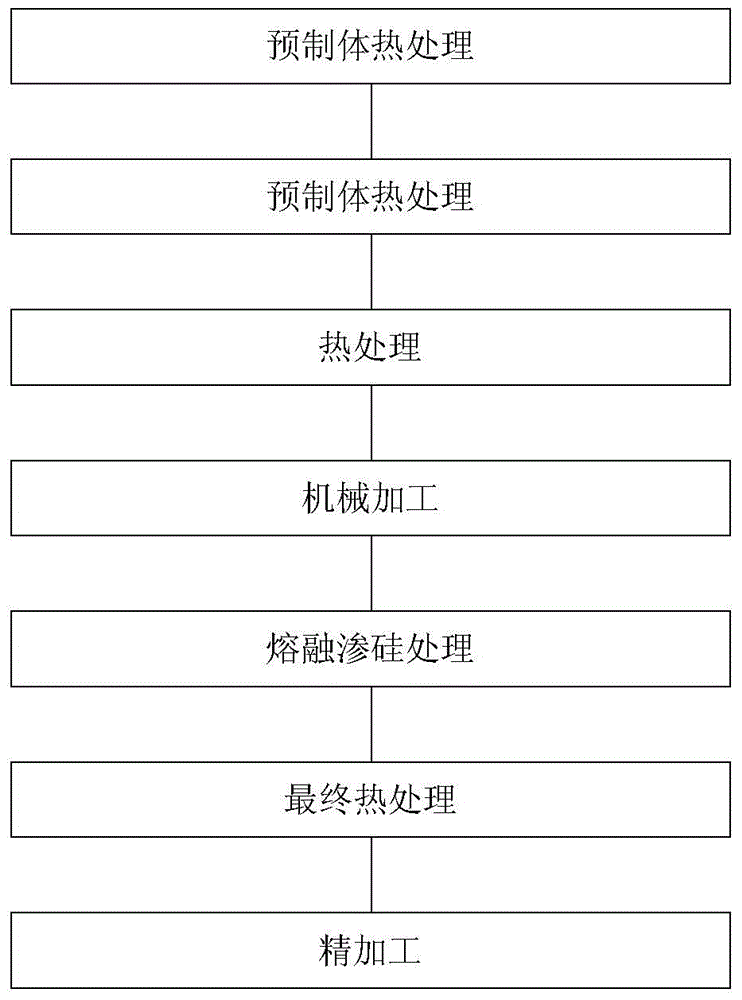

[0024] This embodiment is a method for preparing a high-speed train carbon / ceramic friction couple. The high-speed train carbon / ceramic friction couple includes brake discs and brake pads.

[0025] In this example, a carbon / ceramic composite material is used to prepare a frictional couple of a high-speed train, and the specific steps are as follows:

[0026] Step 1, preform heat treatment. Place the prefabricated body of the brake disc friction plate and the prefabricated body of the brake pad friction block in a heat treatment furnace, and perform heat treatment to remove the glue by conventional methods. The heat treatment temperature is 1600 ° C, and the holding time is 4 hours.

[0027] Step 2, carbon / carbon blank deposition. The brake disc friction plate prefabricated body and the brake pad friction block prefabricated body which have undergone high-temperature heat treatment are respectively placed in a chemical vapor deposition furnace, and deposited according to a co...

Embodiment 2

[0035] This embodiment is a method for preparing a high-speed train carbon / ceramic friction couple.

[0036] In this example, a carbon / ceramic composite material is used to prepare a frictional couple of a high-speed train, and the specific steps are as follows:

[0037] Step 1, preform heat treatment. Place the prefabricated body of the brake disc friction plate and the prefabricated body of the brake pad friction block in a heat treatment furnace, and perform heat treatment to remove the glue by conventional methods. The heat treatment temperature is 1600 ° C, and the holding time is 4 hours.

[0038] Step 2, carbon / carbon blank deposition. The brake disc friction plate prefabricated body and the brake pad friction block prefabricated body which have undergone high-temperature heat treatment are respectively placed in a chemical vapor deposition furnace, and deposited according to a conventional process. The gas source of the brake disc friction plate is propylene gas, the...

Embodiment 3

[0045] This embodiment is a method for preparing a high-speed train carbon / ceramic friction couple.

[0046] In this example, a carbon / ceramic composite material is used to prepare a frictional couple of a high-speed train, and the specific steps are as follows:

[0047] Step 1, preform heat treatment. Place the prefabricated body of the brake disc friction plate and the prefabricated body of the brake pad friction block in a heat treatment furnace, and perform heat treatment to remove the glue by conventional methods. The heat treatment temperature is 1600 ° C, and the holding time is 4 hours.

[0048] Step 2, carbon / carbon blank deposition. Put the brake disc friction plate prefabricated body and the brake pad friction block prefabricated body which have undergone high temperature heat treatment into a chemical vapor deposition furnace respectively, and deposit according to a conventional process. The gas source of the brake disc friction plate is propylene gas, the deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com