A kind of aluminum alloy material and application for high temperature brazing aluminum/steel composite strip

An aluminum alloy material and aluminum alloy technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as easy peeling off of the aluminum layer, product failure, and reduction of the interface strength of the aluminum/steel composite strip. Overcomes the effect of low binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

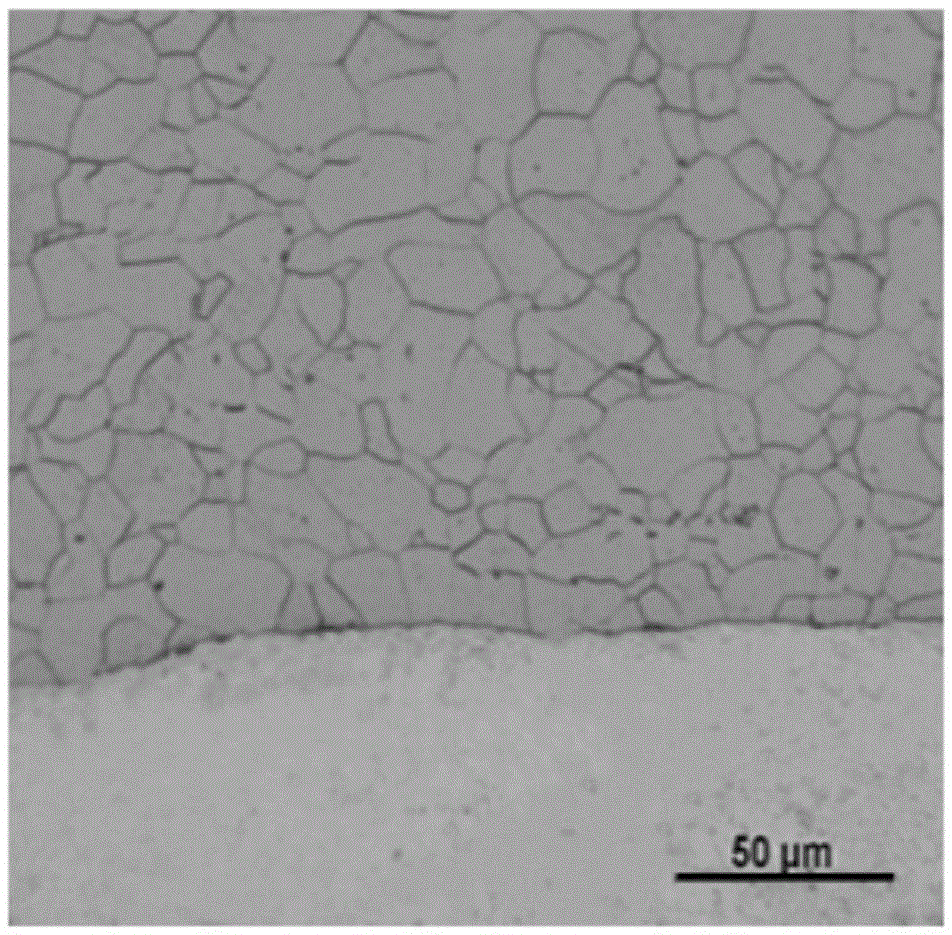

[0021] Example 1: The Al-0.8Si-0.05Er / steel heat treatment+simulated brazing treatment interface prepared by the aluminum alloy in A4 does not observe the existence of interface compounds, and the interface bonding is good, see figure 1 .

Embodiment 2

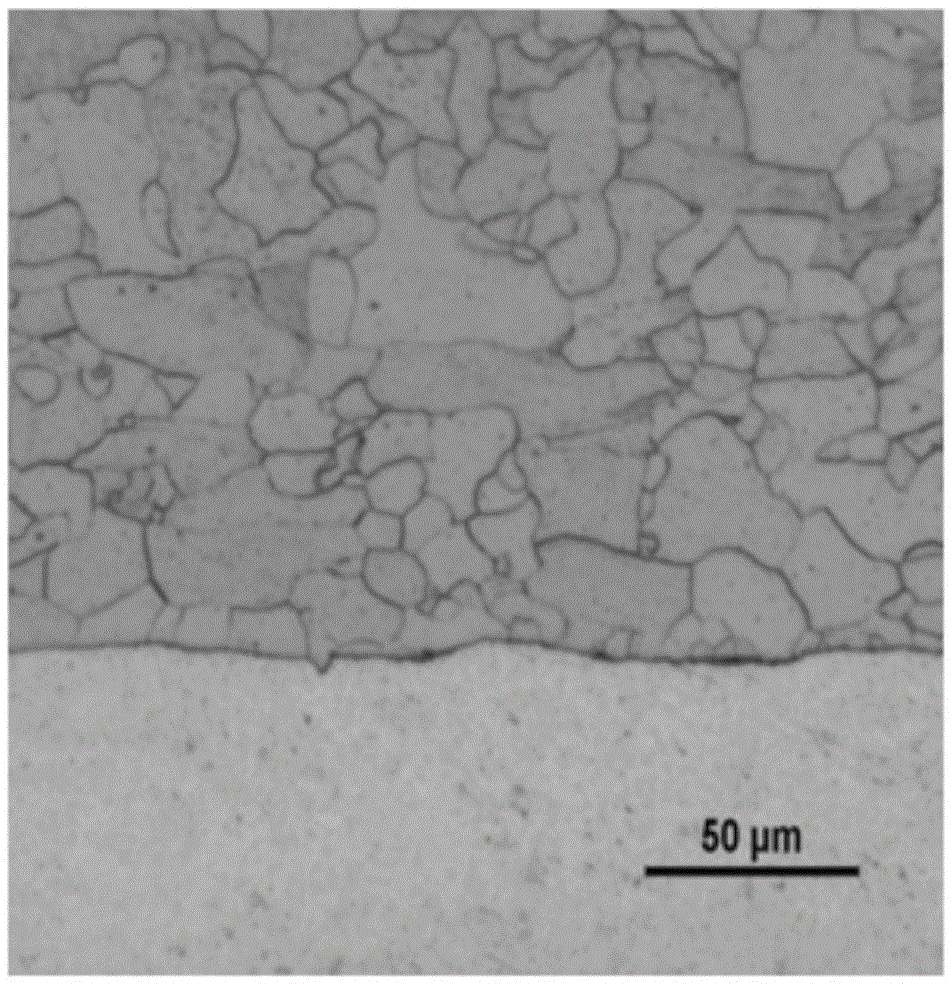

[0022] Example 2: The Al-0.8Si-0.10Er / steel heat treatment+brazing treatment interface in A5 also does not observe the existence of interface compounds, and the interface bonding situation is good, see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com