Control method of frequency conversion compressor of heat pump clothes dryer and heat pump clothes dryer

A frequency conversion compressor and control method technology, which is applied in the control field of heat pump dryers and frequency conversion compressors of heat pump dryers, can solve the problems of high failure rate of compressor motors and reduced service life, etc., so as to reduce energy consumption and increase Effect, the effect of reducing the possibility of frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

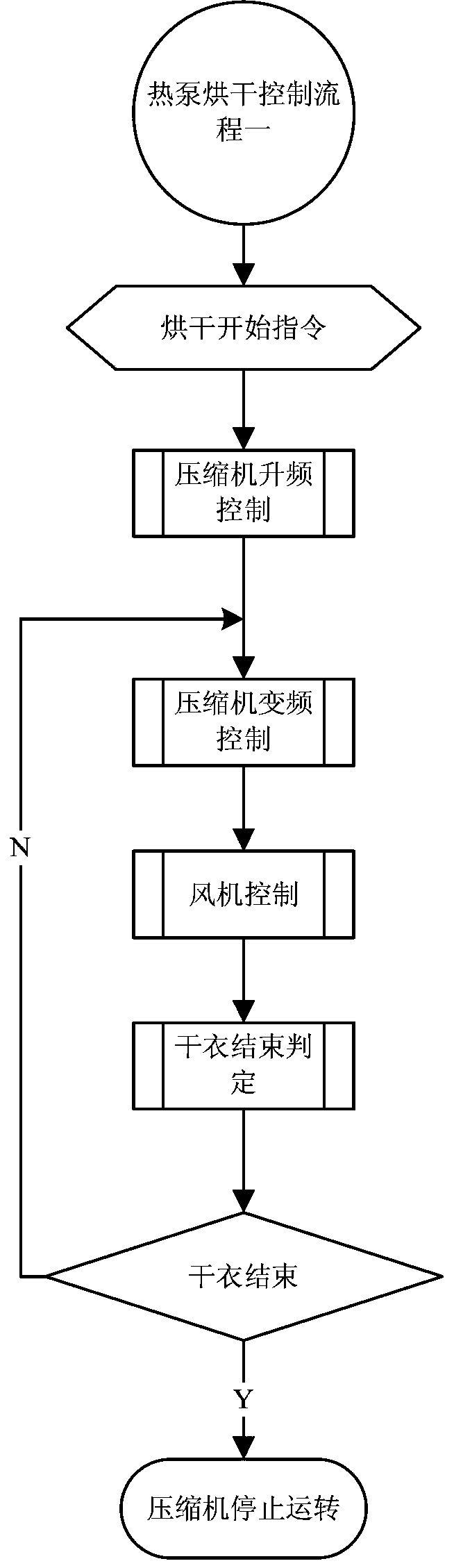

[0040] Such as image 3 As shown in , it is a schematic diagram of the drying workflow of the heat pump clothes dryer described in this embodiment. During the drying process, the operating frequency of the frequency conversion compressor is controlled in stages, including compressor frequency increase control, compressor frequency conversion control, fan control and drying end judgment from the beginning to the end. conditions, then repeat the process of frequency conversion control of the compressor, fan control, and the determination of the end of drying in a cycle. Among them, the frequency increase control of the compressor refers to controlling the frequency conversion compressor to increase to the final frequency H0 and running stably; the frequency conversion control of the compressor refers to the corresponding Detect the temperature and adjust the operating frequency of the variable frequency compressor in stages.

[0041] The above detection temperature refers to th...

Embodiment 2

[0044] Such as Figure 4 As shown, in this embodiment, on the basis of the first embodiment above, the following control mode is added between the compressor frequency up control and the frequency conversion control to detect whether the input current of the frequency conversion compressor or the exhaust temperature of the compressor or the temperature of the condenser reaches the upper limit, If the upper limit condition is reached, it will directly enter the frequency conversion control of the compressor; if the upper limit condition is not reached, the frequency conversion compressor will be controlled to increase the frequency to control the final frequency to run for a set time such as t=30min or to detect the temperature such as the temperature of the condenser or the output cylinder temperature. After setting the value, enter the frequency conversion control of the compressor. The condition of the upper limit refers to the maximum current allowed by the compressor, or t...

Embodiment 3

[0046] Such as Figure 5 As shown, in this embodiment, on the basis of the first embodiment, an evaporator anti-frost control stage is added between the compressor frequency up control and the frequency conversion control. The evaporator anti-frost control stage is to control the rapid rise of the air temperature entering the evaporator; since frost is usually related to temperature and humidity, when it is detected that the evaporator is about to frost, the operating frequency of the inverter compressor is controlled to increase rapidly so that the cylinder Underwear heats up quickly and dries to reduce humidity and the temperature of the air passing through the evaporator rises quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com