A multi-cone drill bit

A roller cone bit and drill bit technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of multiple dead angles, affect the drilling efficiency of the drill bit, and affect the extension of the drill body, so as to reduce the dead angle and improve the drilling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

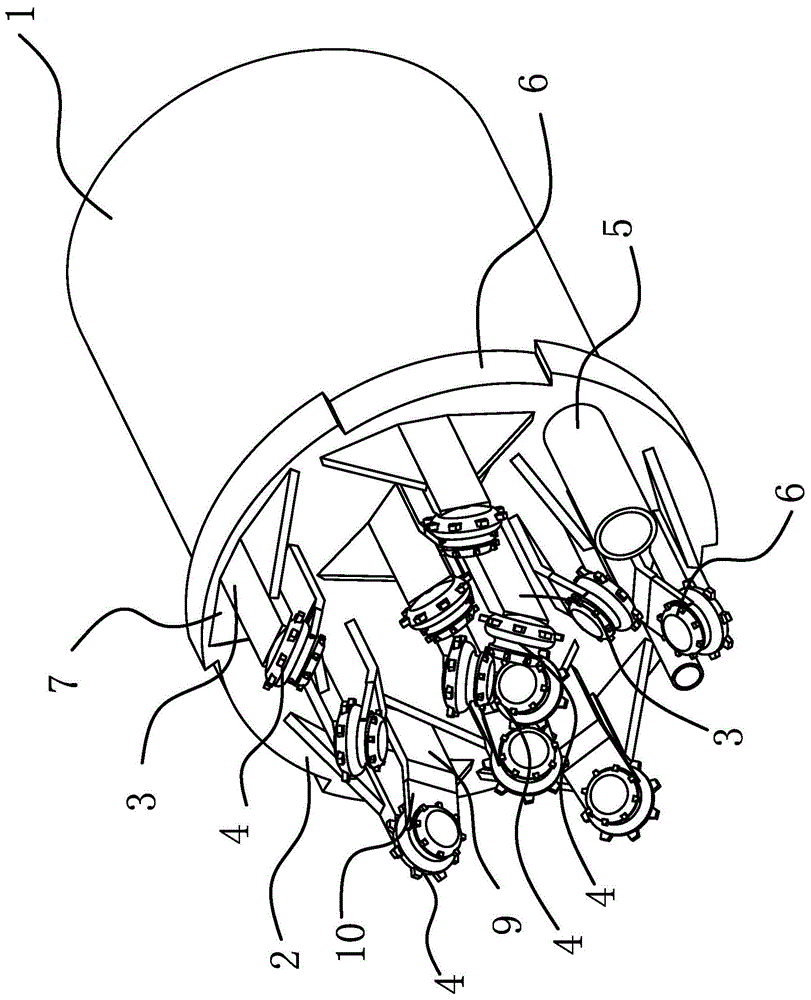

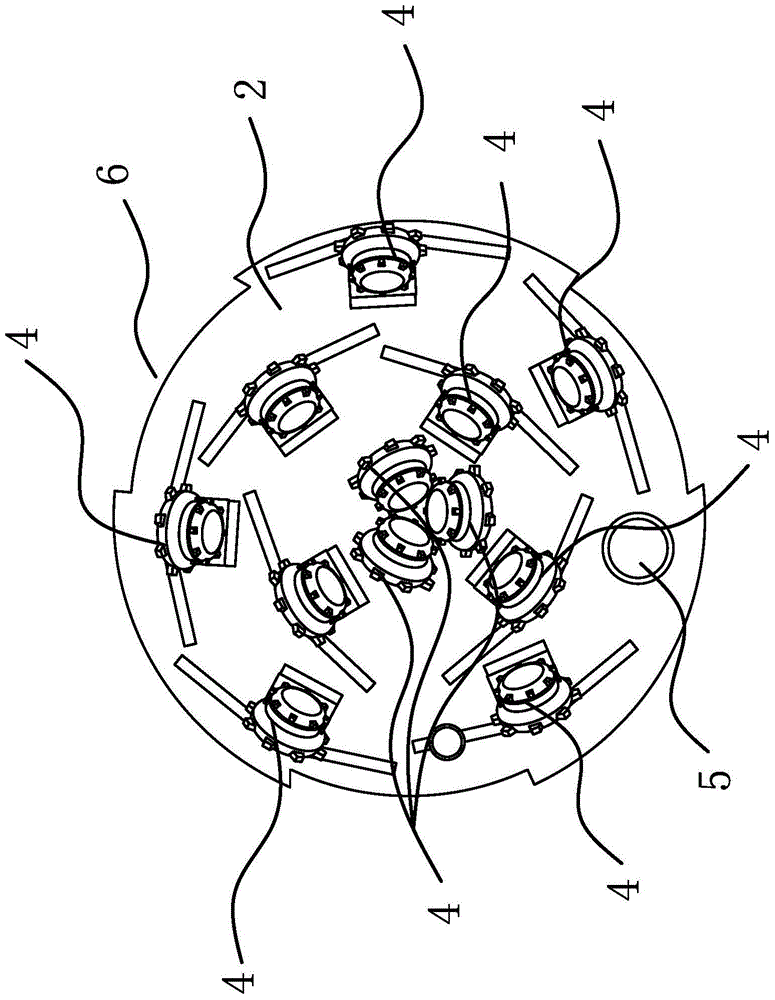

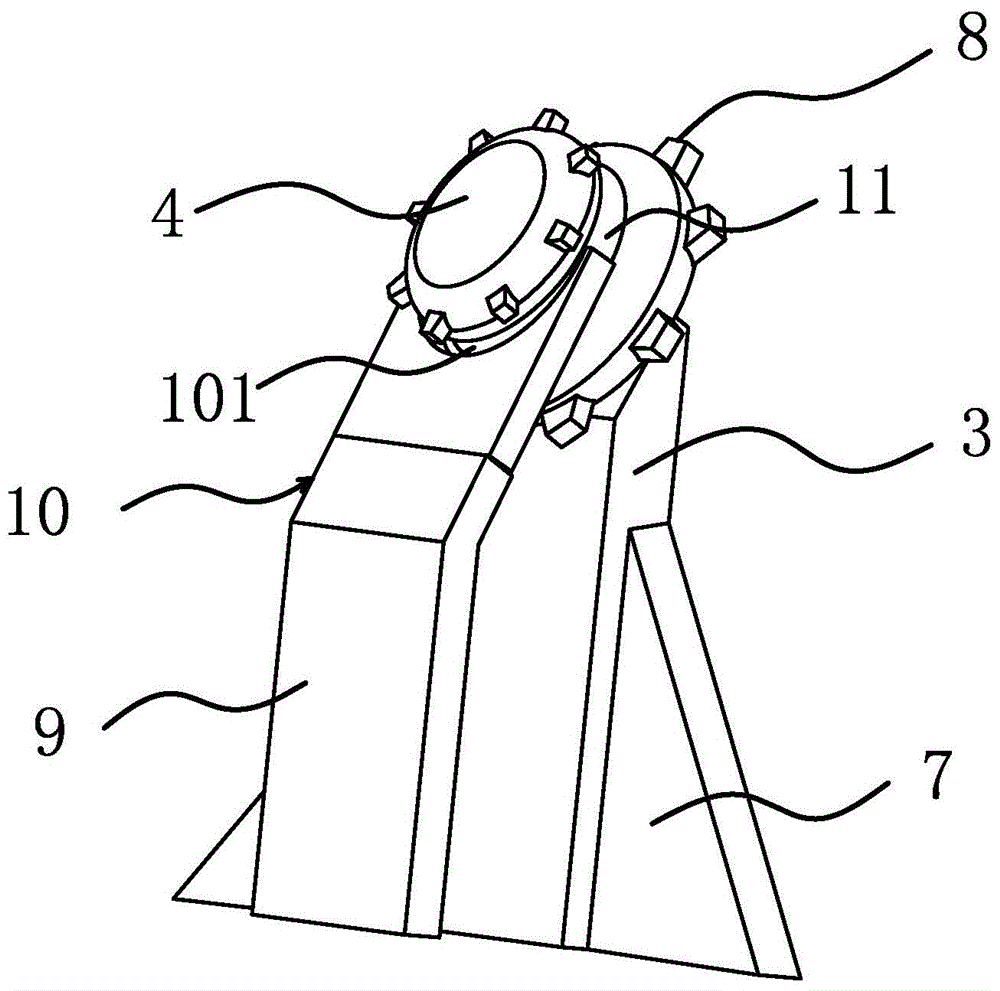

[0026] Such as figure 1 , figure 2 , image 3 As shown, the drill bit includes a drill body 1. One end of the drill body 1 has a circular mounting plate 2. At least one cone 4 is rotated on the area of the circular mounting plate 2 close to its center line. The circular mounting plate 2 is far away from the At least two cones 4 are rotated on the area of its own center line, and the distance between each cone 4 located away from the center line of the circular mounting plate 2 and the center line of the circular mounting plate 2 is completely unequal or partially not equal. As a preference, three cones 4 are rotated on the area of the circular mounting plate 2 close to its own center line, and the three cones 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com