Pressure balance type gas ultrasonic transducer

A transducer and balanced technology, applied in the field of pressure-balanced gas ultrasonic transducers, can solve the problems of reducing the amplitude of the effective ultrasonic signal, affecting the ultrasonic flowmeter, increasing the compression degree of metal seals, etc. Guaranteed sound path, good balance and sensitivity, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further specifically described below in conjunction with the embodiments and accompanying drawings.

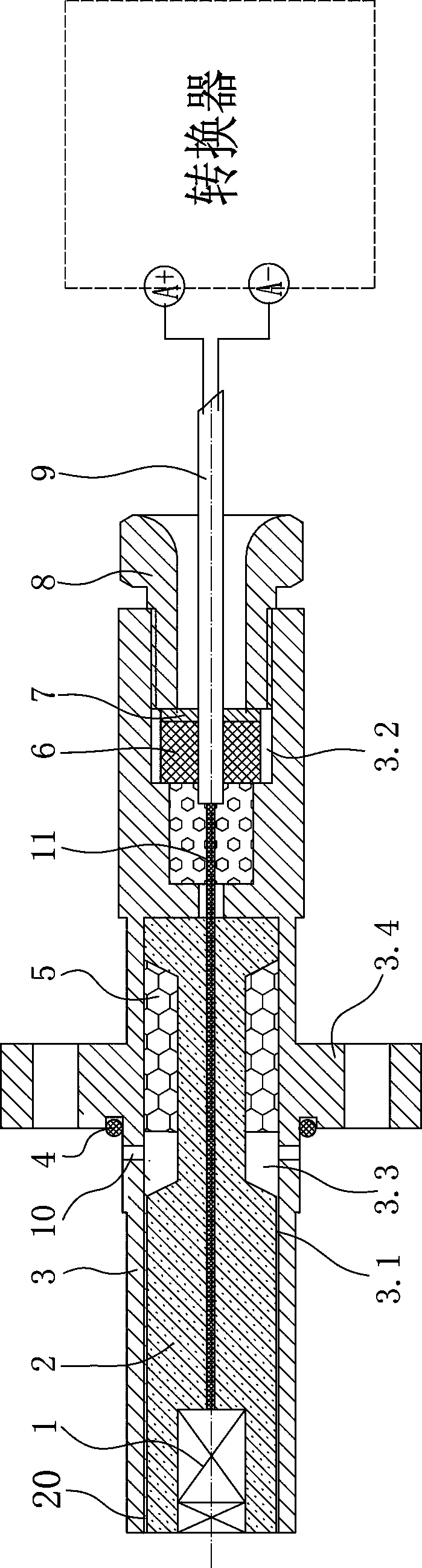

[0014] See figure 1 The pressure-balanced gas ultrasonic transducer shown includes a housing 3, and the housing 3 is divided into a front chamber 3.1 and a rear chamber 3.2. An elastic sound-absorbing lining 2 is built in the front chamber 3.1, and the lining 2 is made of sound-absorbing material and rubber. The front end of the lining 2 is in an open state without a sealed structure and is equipped with a sensitive element 1 with a transducer. The sensitive element 1 is made of an ultrasonic vibrator (piezoelectric crystal) and a matching layer bonded by glue. The signal lead wire 9 of the sensitive element 1 Pass through the liner 2 to the back chamber 3.2 to externally connect the additional converter in the flowmeter. The rear end of the lining 2 extends to the bottom of the anterior chamber 3.1, and the rear part of the lining 2 shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com