A drop pill hardness tester

A detector and dropping pill technology, applied in the field of dropping pill hardness detector, can solve the problems of inability to release essence, difficult to destroy dropping pills, low efficiency, etc., and achieve the effects of saving detection time, improving service life and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

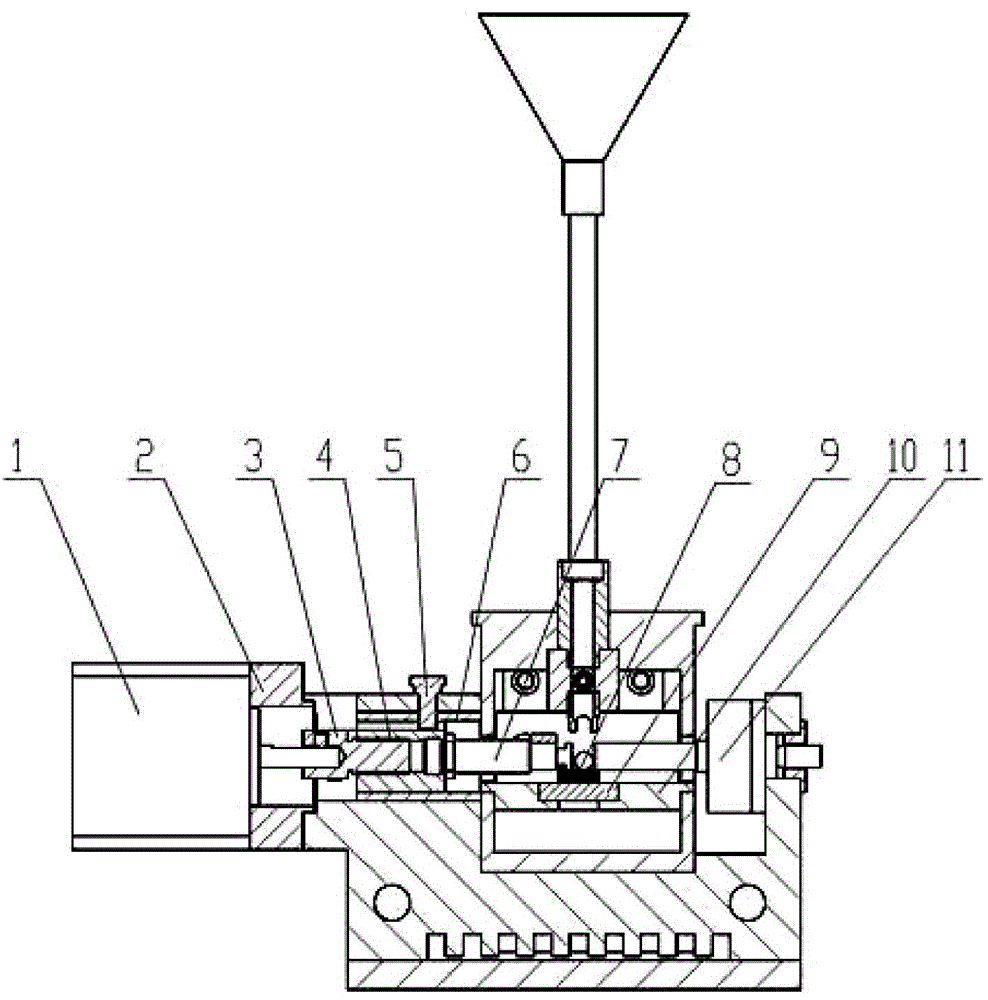

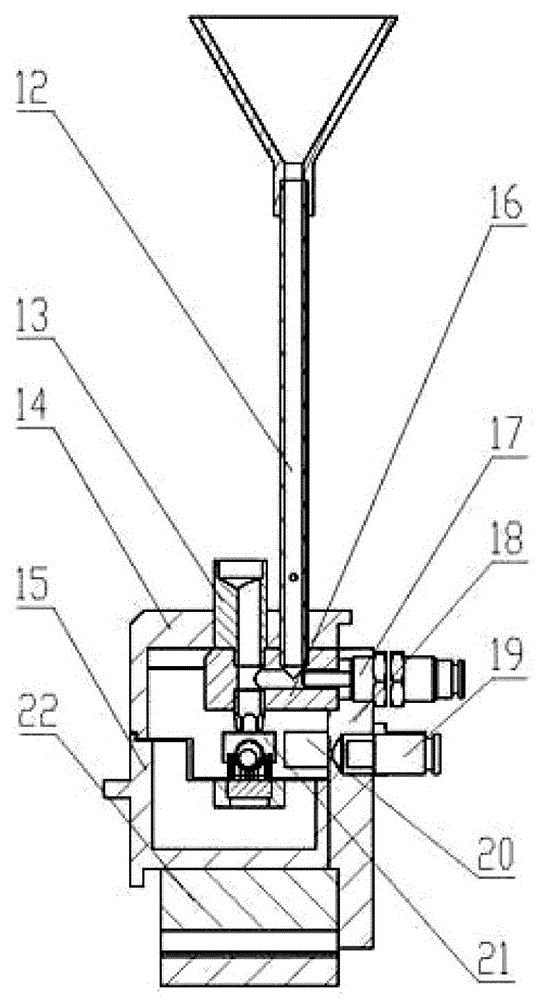

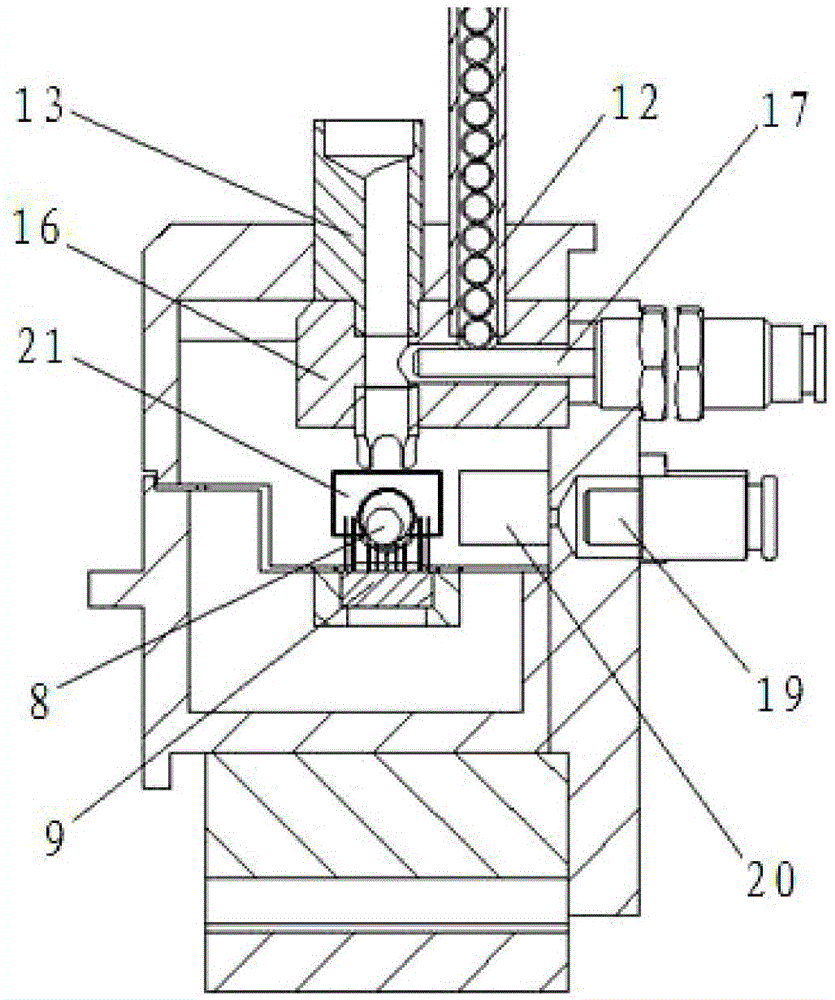

[0020] Such as Figure 1-3 As shown, the present invention includes a motor 1 , a screw mandrel 3 , a moving nut 4 , a pin shaft 5 , a steel sleeve 6 , a push rod 7 , a pressure sensor 11 and an installation base 22 . The motor 1 is installed on the left side of the installation base 22 through the connecting plate 2, the middle part of the installation base 22 is provided with a groove, and the installation base 22 on the left side of the groove is provided with an inner hole, and the steel sleeve 6 is set on the installation base 22 In the inner hole on the left side of , the moving nut 4 is set in the steel sleeve 6, the outer ring of the moving nut 4 fits the inner ring of the steel sleeve 6, the outer ring of the moving nut 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com