Nozzle module for transversal flow injection iodine mixing nozzle experiment research

An experimental research, cross-flow technology, applied in the field of nozzle modules, can solve problems such as immature development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

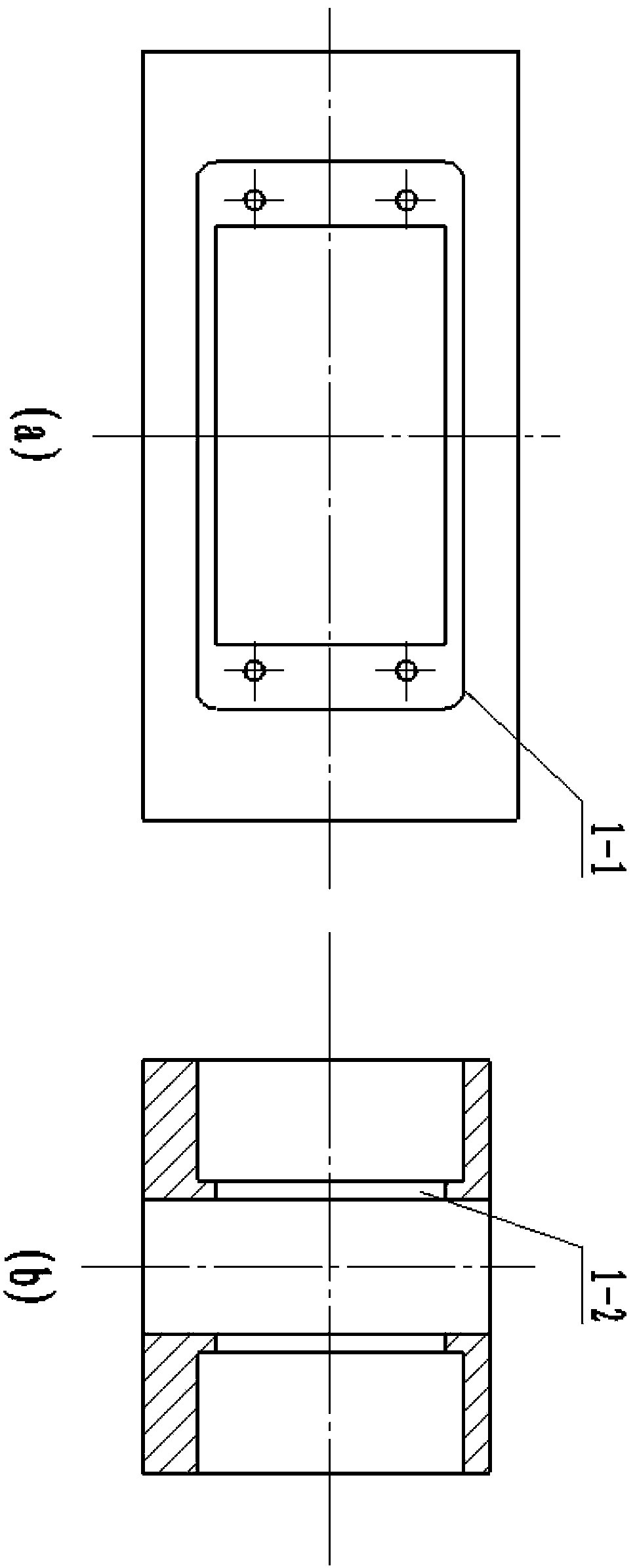

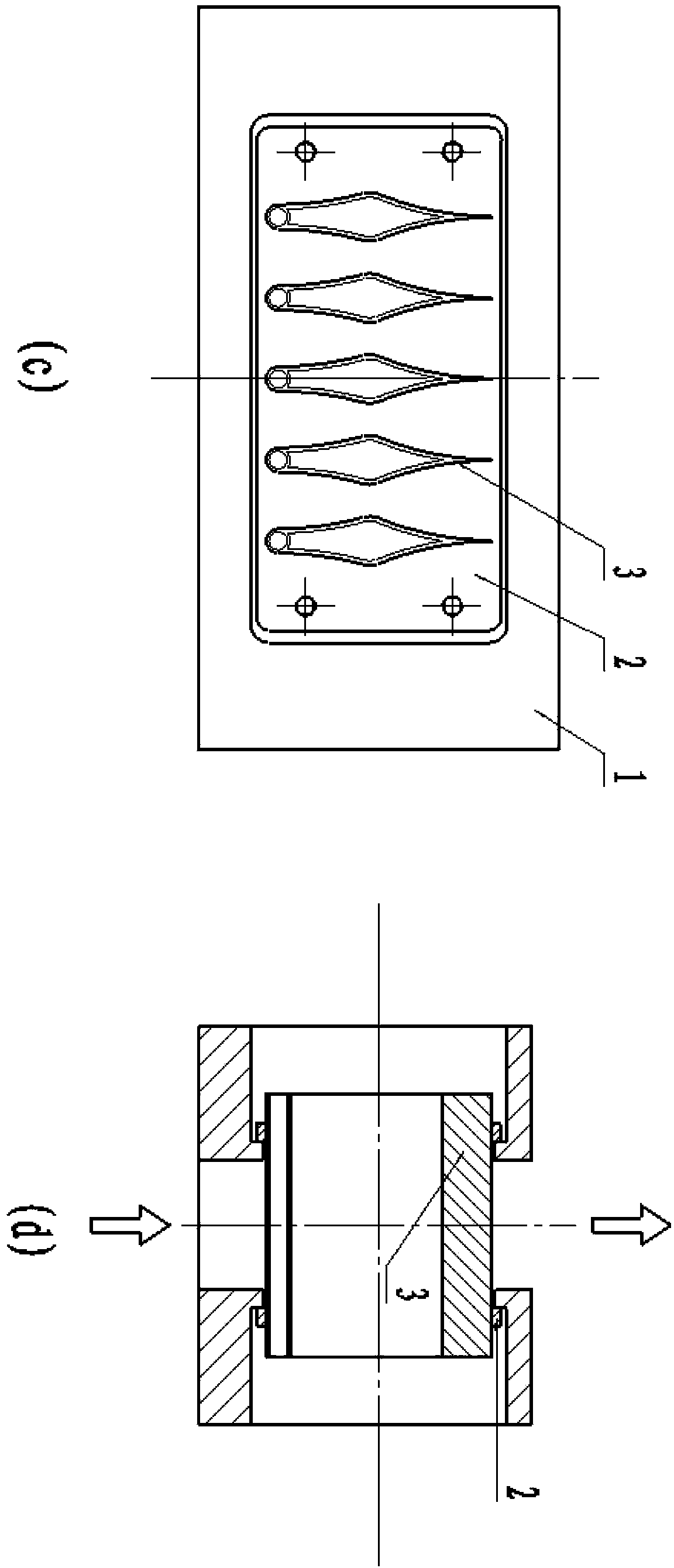

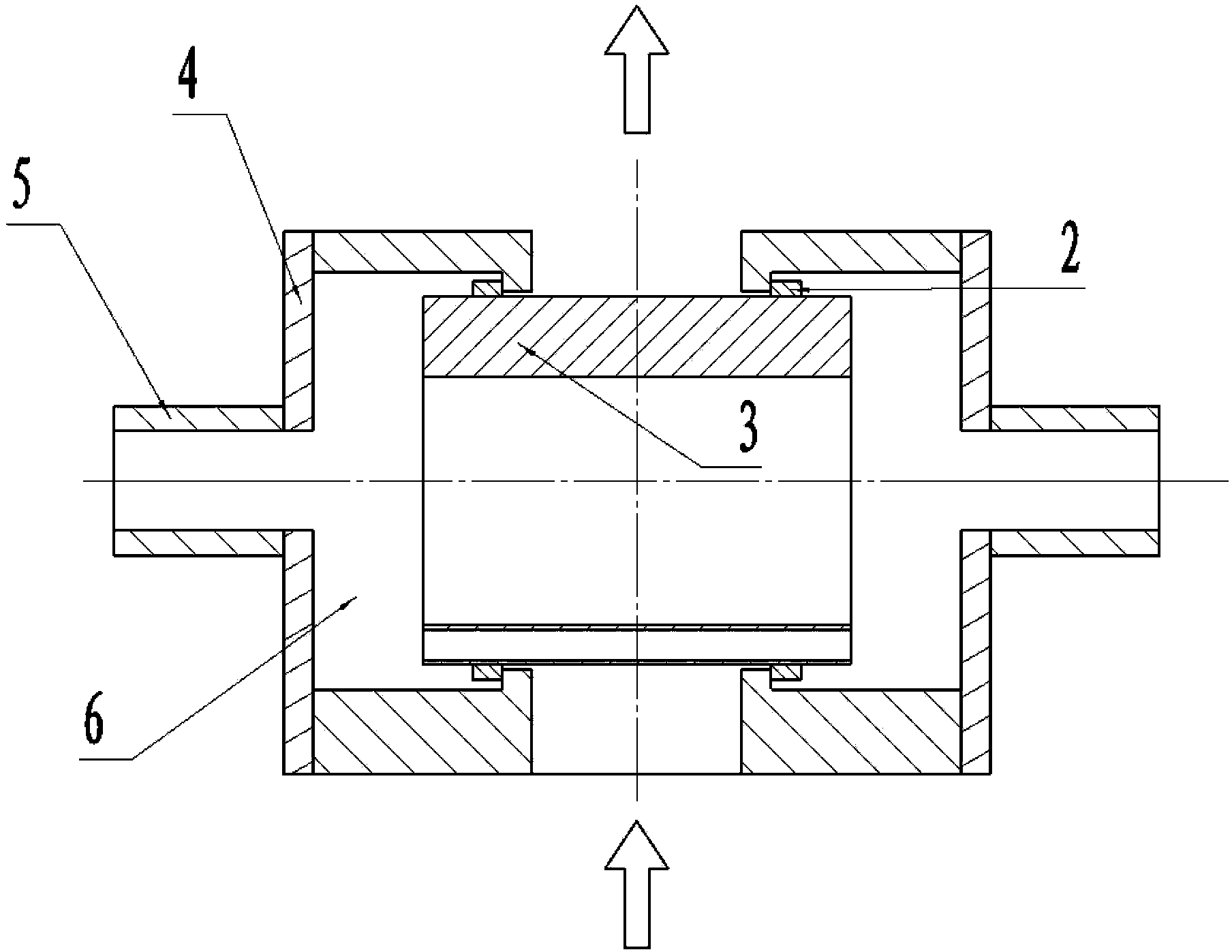

[0032] A nozzle module used for the experimental research of the iodine mixing nozzle with lateral flow ( image 3 ). This module is applied to the experimental research of the key component of the supersonic oxygen iodine chemical laser - the nozzle module. The module uses a nozzle fixing plate that can be easily disassembled and replaced, so that the nozzles of various structural designs and the throat distance of the nozzles can be easily replaced or adjusted.

[0033] The nozzle module used for the experimental research of the iodine mixed nozzle with lateral flow injection, including the module main body 1, the nozzle fixing plate 2, the iodine injection nozzle 3, the iodine sealing cover 4, the secondary airflow (iodine vapor and its carrier gas) inlet pipe 5.

[0034] During the experimental research, the module main body 1 is installed in the nozzle section of the supersonic oxygen iodine chemical laser, as the nozzle of the supersonic oxygen iodine chemical laser;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com