Concurrent flow ultrasonic oxygen-iodine mixing nozzle

A supersonic, parallel flow technology, used in laser parts, electrical components, lasers, etc., to solve problems such as slow pipeline flow rate and O2 loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

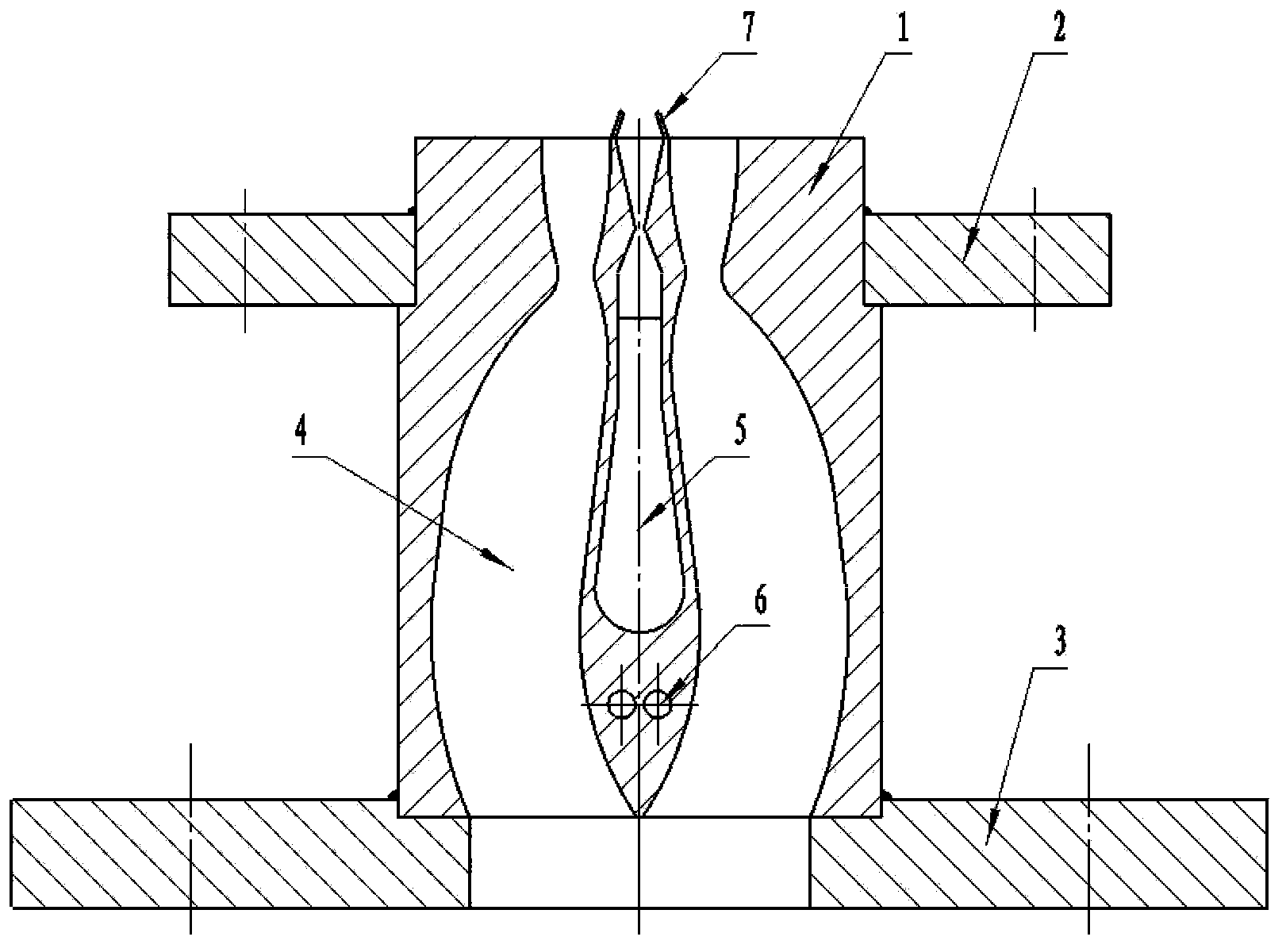

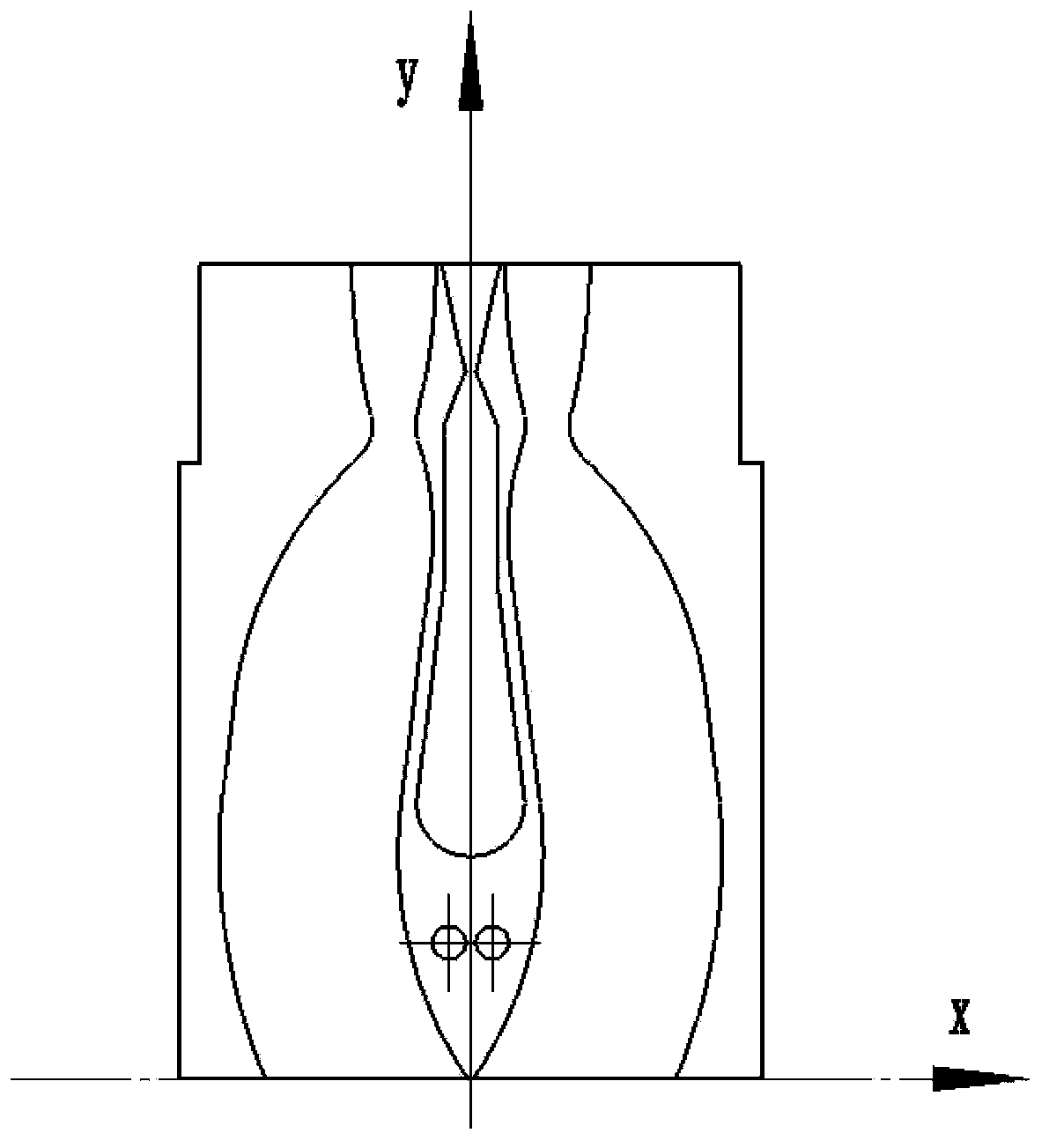

[0049] A parallel-flow supersonic oxygen-iodine mixing nozzle is used for supersonic iodine-injected oxygen-iodine chemical laser light operation or parallel-flow supersonic mixed flow field research. Its main components are ( figure 1 ): Nozzle main body 1, upper flange 2, lower flange 3, oxygen nozzle 4, iodine nozzle 5, heating hole 6, disturbance fin 7.

[0050] An upper flange (2) and a lower flange 3 are respectively provided on the nozzle main body 1 of the inlet of the oxygen nozzle 4 and the outlet of the oxygen nozzle 4. The upper flange adopts a sinking design, that is, the connection surface between the upper flange and the main body is located at Below the outlet plane of the nozzle; in this way, when connecting with the upper test section, the lowest visible surface of the window of the test section can be flush with the outlet of the nozzle to facilitate the flow field test research; the lower flange 3 is connected to the singlet oxygen generator connect.

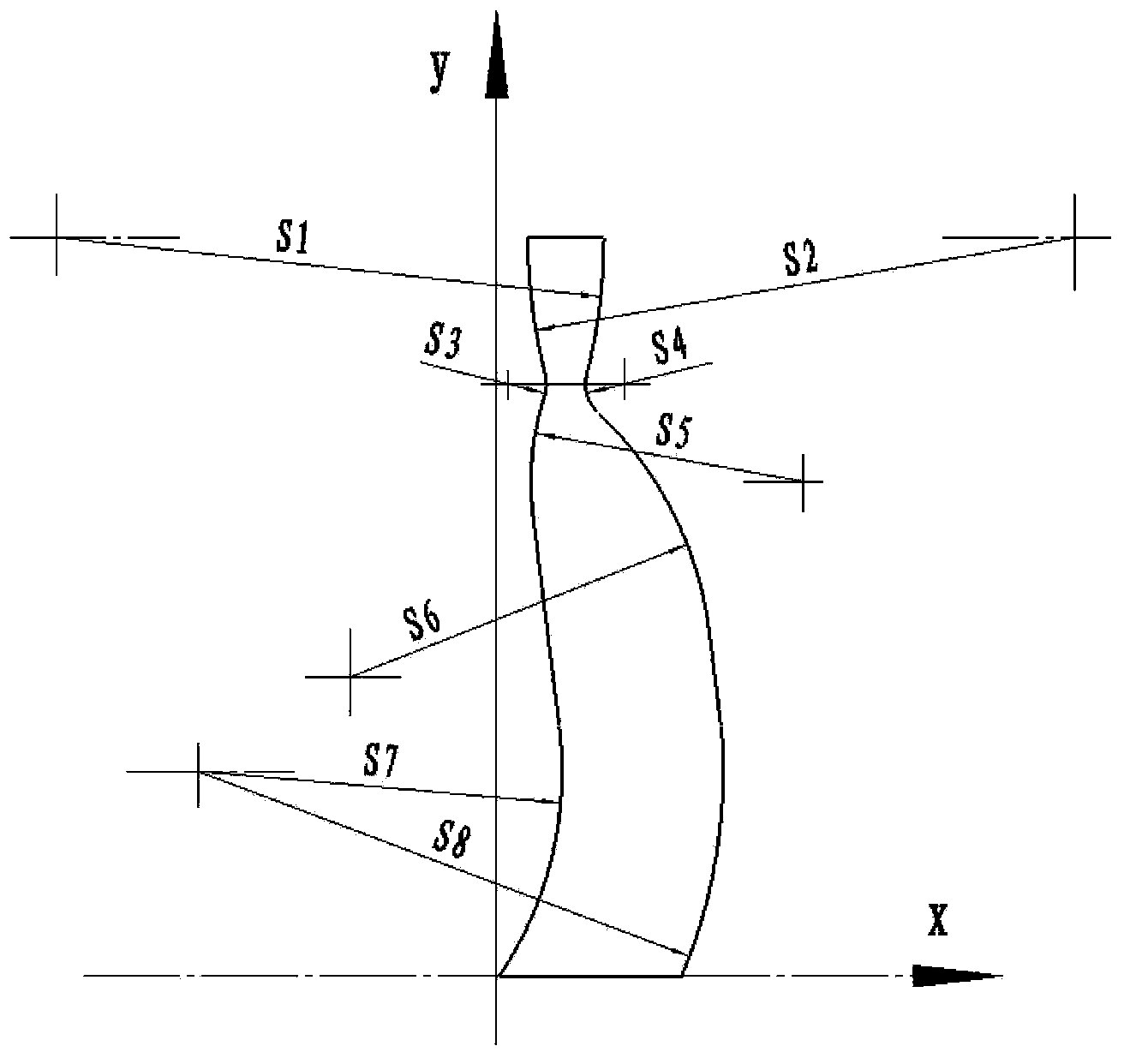

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com