Compound comprising PLLA and PDLA

A composition and polymer technology, applied in the field of compositions containing PLLA and PDLA, can solve the problems that PLA is slow and cannot be applied on an industrial scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

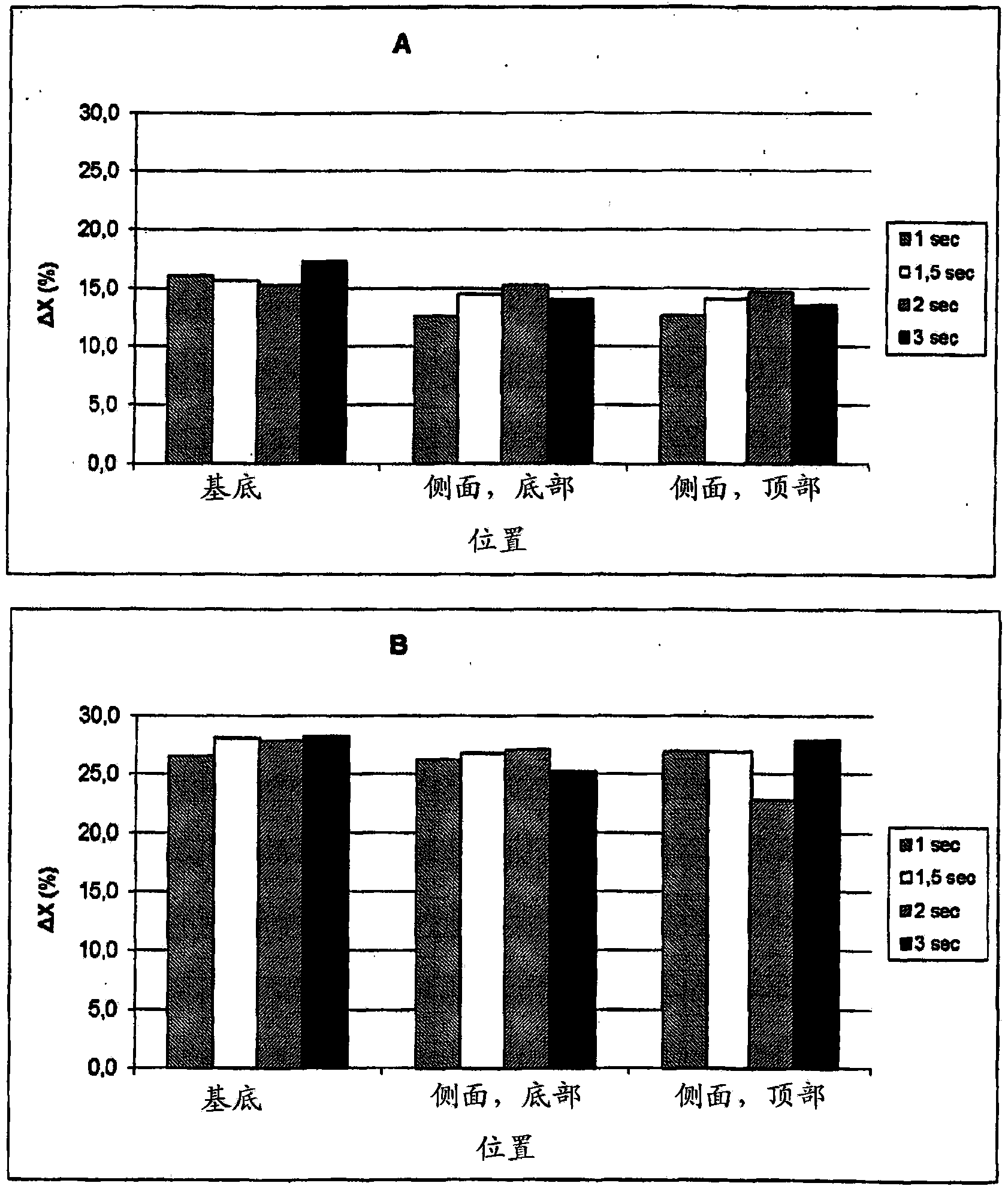

Examples

Embodiment 1

[0044] Embodiment 1 (prior art)

[0045] It is known from the literature that adding a nucleating agent to PLA is a method to rapidly crystallize PLA at high temperature and obtain a higher deformation temperature. In this example, make Ingeo TM (Natureworks) mixed with two nucleating agents (ULTRATALC609 and LAK-301) to increase the crystallization rate.

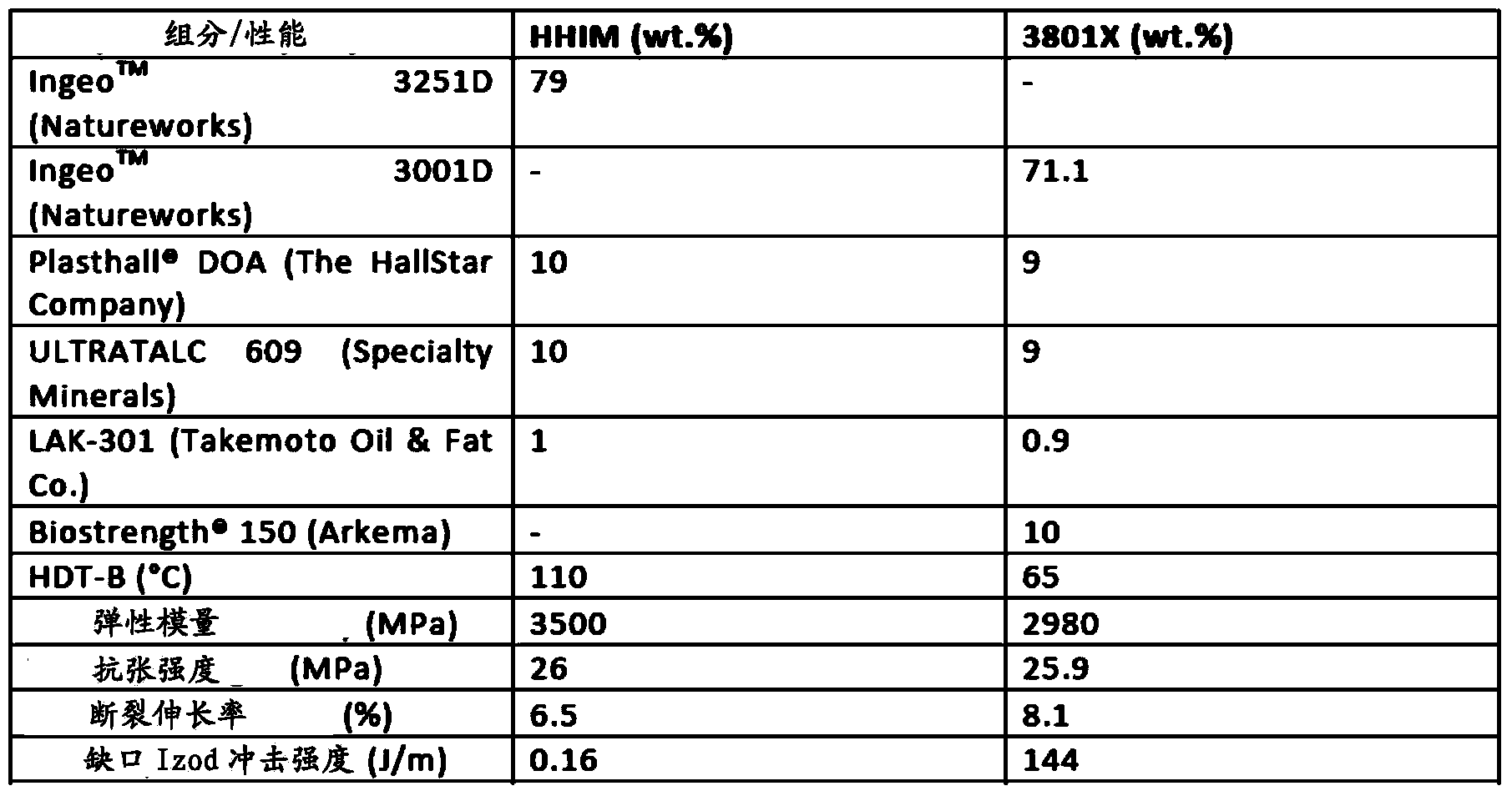

[0046] Table 1 presents the results obtained by Natureworks for the compositions HHIM and 3801X. Table 1 shows the components, and the amount of each component is expressed in weight percent (wt %) relative to the total weight of the composition.

[0047] As expected, higher crystallization rates (HDT-B values) were obtained after crystallization, but the crystallization rates were found to be still too low, resulting in longer cycle times (greater than 150 seconds). For this reason, these formulations are not yet suitable for industrial use for injection molding or thermoforming.

[0048] Table 1Ingeo TM HHIM&3801X ...

Embodiment 2

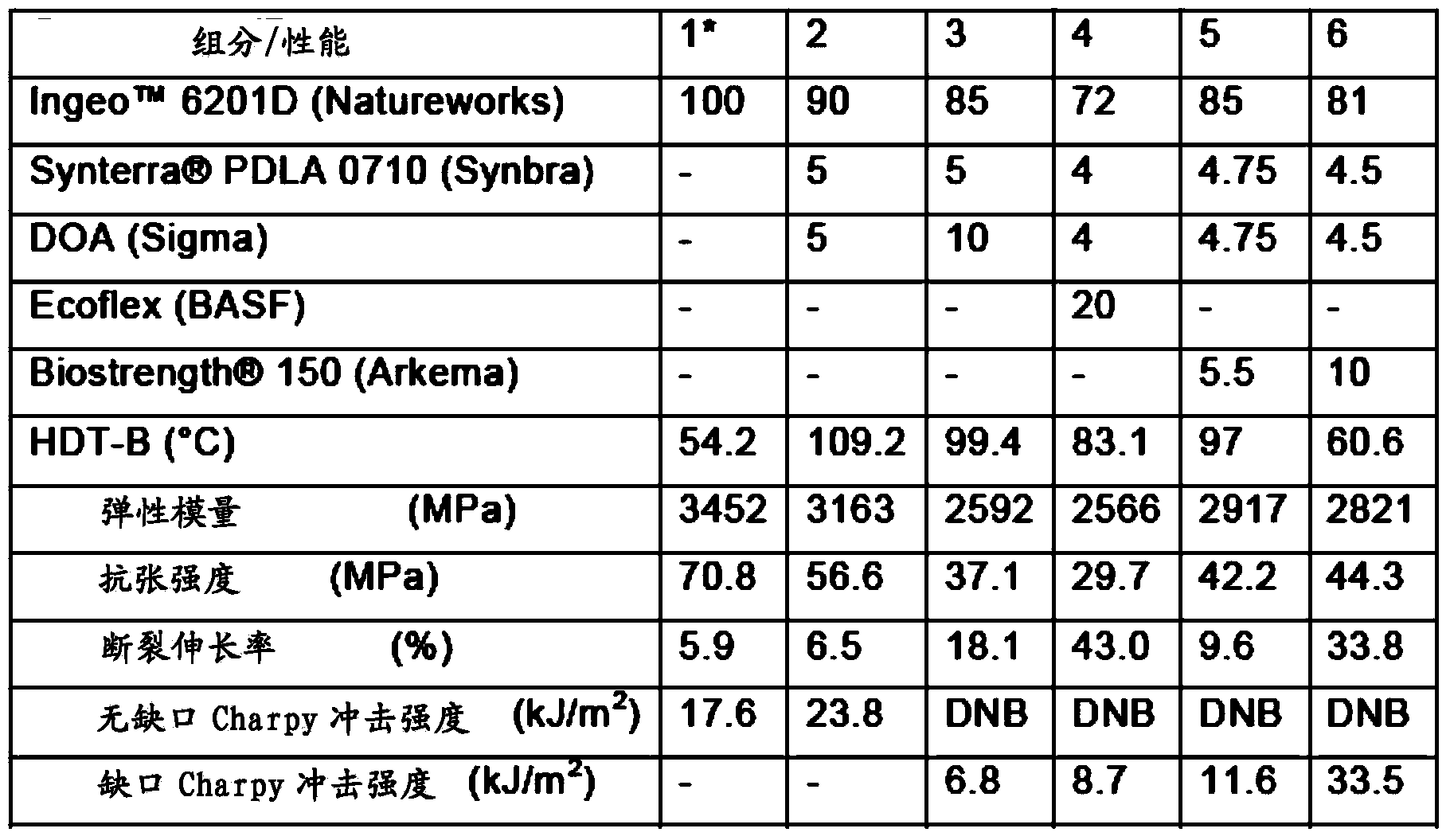

[0051] Example 2 shows that PDLA with an optical purity of 99.5% can be used as a nucleating agent for PLA. As in the previous examples, higher HDT-B values were obtained after crystallization. Additionally, an increase in tensile strength was observed when PDLA having an optical purity of at least 99.5% was present. Especially in the case of samples 3-6, relative to the composition of example 1, a significant increase in tensile strength and elongation at break was observed.

[0052] Table 2Ingeo TM 6201D&PDLA (*comparative example)

[0053]

Embodiment 3

[0055] The following examples show that PDLA can also increase the crystallization rate of PLLA. When PLLA is optically pure, the crystallization rate in combination with PDLA is significantly higher than in the previous examples. Better HDT-B values are obtained after crystallization. And again better mechanical properties were observed.

[0056] Table 3 PLLA & PDLA

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com