Respirator or anesthetic apparatus and oxygen concentration auto-checking method

An automatic calibration and ventilator technology, applied in the direction of respirators, etc., can solve the problems of oxygen sensor zero point value drift, affect oxygen concentration monitoring, oxygen concentration control and monitoring inconsistency, etc., to achieve the effect of ensuring accuracy and short execution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

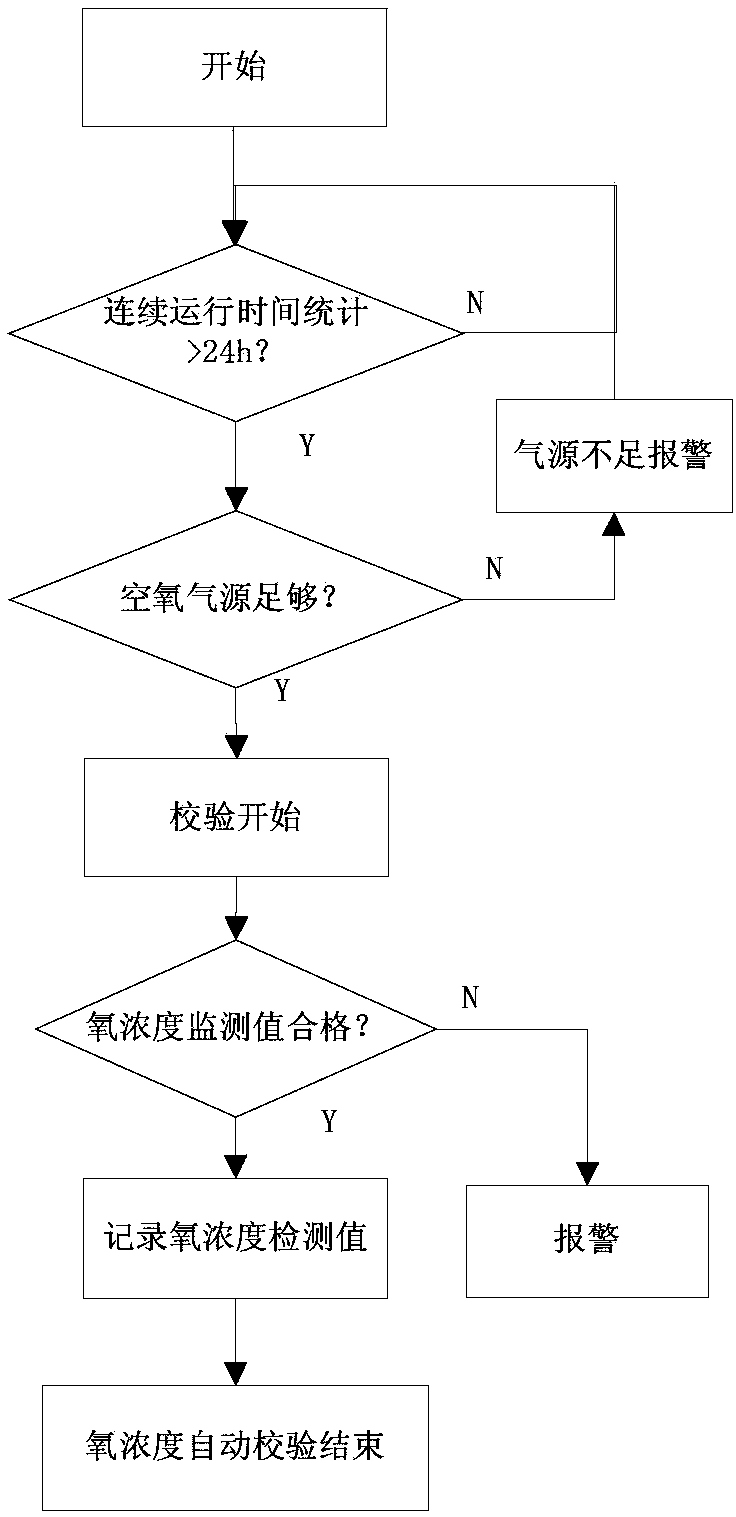

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as figure 1 As shown, the present invention provides an automatic calibration method for the oxygen concentration of a ventilator or anesthesia machine, which is suitable for automatically checking the oxygen concentration when the ventilator or anesthesia machine has been running for a long time, and the automatic calibration process is executed The short time will not affect the control of the current oxygen concentration. At the same time, the display unit will also display the relevant information of the automatic calibration of the oxygen concentration, which can ensure the accuracy of the oxygen concentration detection value during the long-term continuous operation of the ventilator or anesthesia machine. Specifically, it includes the following step:

[0024] Step A: During the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com