Tool clamp used in elevator safety tongs

A tooling fixture and safety gear technology, which is applied in the field of tooling fixtures, can solve problems such as low production efficiency, difficult accurate positioning, and high consumption, and achieve the effects of simple structure, improved work efficiency and workpiece accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

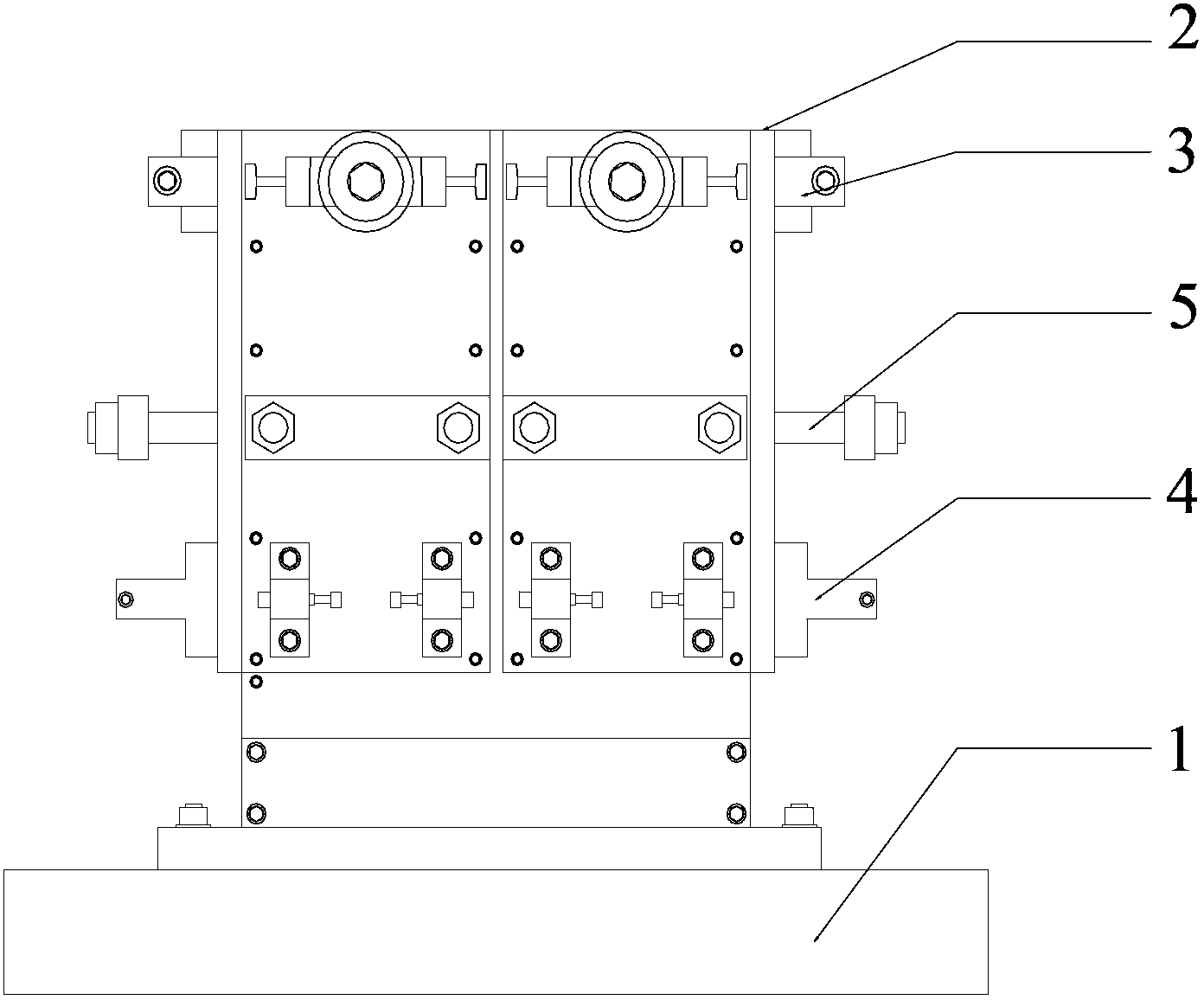

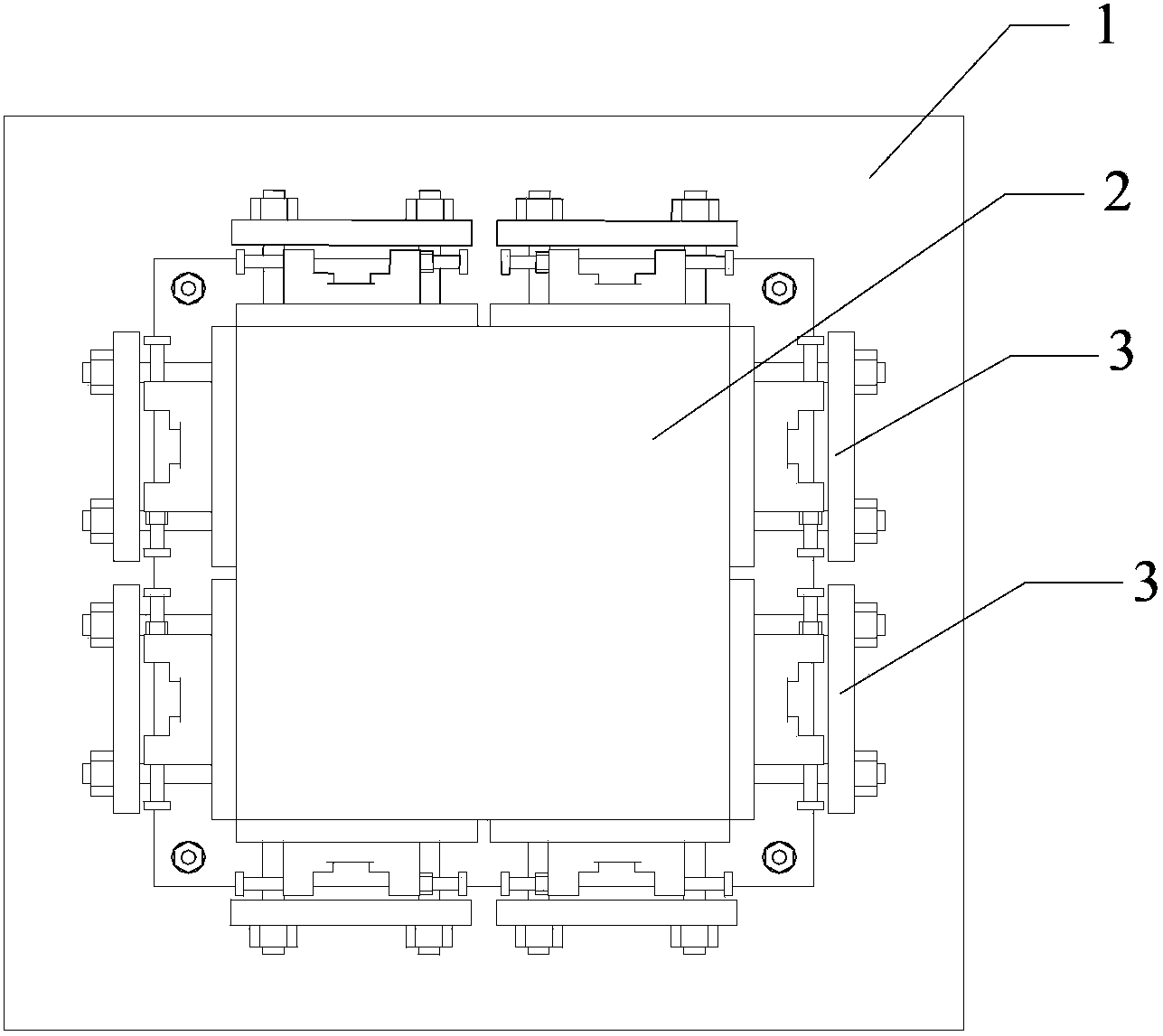

[0017] A tooling clamp used in elevator safety gear, its structure is as follows Figure 1-2 As shown, including the base 1, the support 2, the upper baffle 3 and the lower baffle 4, the support 2 is installed on the base 1, and the upper baffle 3 and the lower baffle are installed on the four surfaces of the support 2 4. Two upper baffles 3 and two corresponding lower baffles 4 are installed on each surface, which are respectively used to clamp the elevator safety gear. In addition, between the upper baffle 3 and the lower baffle 4 there are A bolt 5 for fixing is provided, and the bolt 5 is installed on the fixing plate to further fix the position of the elevator safety gear. When in use, eight workpieces can be installed at one time, which improves work efficiency and workpiece accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com