CVT (constant-voltage transformer) driving system and motorcycle

A drive system and driven shaft technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve problems such as affecting the shockproof, compact and safety performance of the whole vehicle, affecting the long-term operation of the transmission mechanism, and adversely affecting the heat dissipation of the transmission mechanism. , to achieve the effect of facilitating heat dissipation, convenient installation and arrangement, and smooth heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

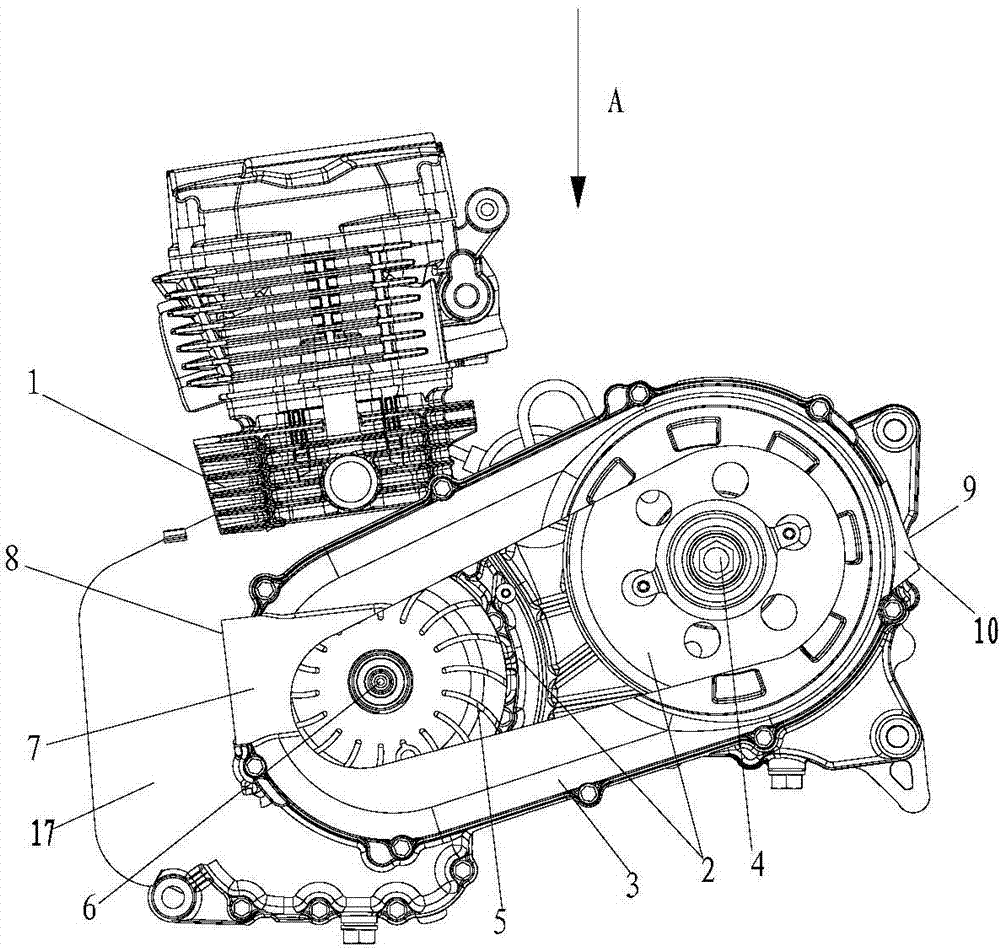

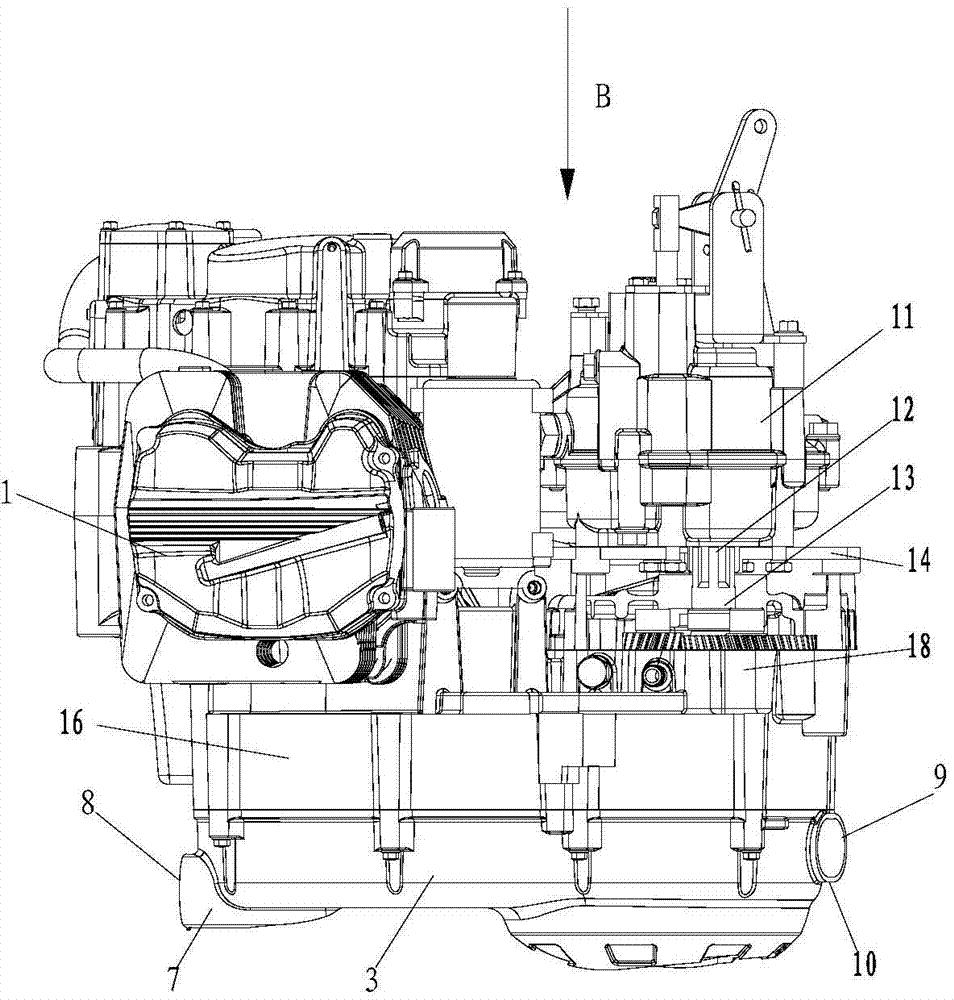

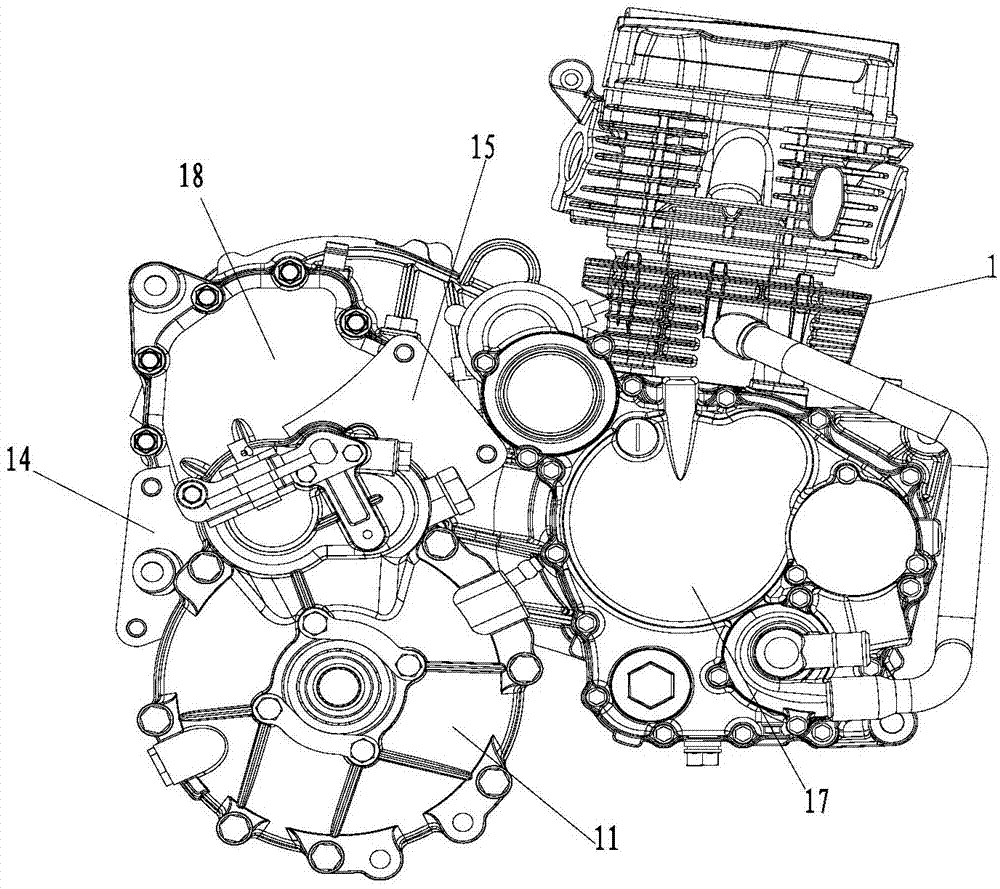

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 2 View along direction B, Figure 4 It is a schematic diagram of the three-dimensional structure of the present invention (remove the side end cover), as shown in the figure: the CVT drive system of this embodiment includes an engine 1 and a CVT2 that cooperates with the crankshaft transmission of the engine, the driving shaft 6 of the CVT and the driven shaft of the CVT 4 parallel, and the driven shaft 4 of the CVT is located obliquely above the driving shaft 6 of the CVT; the driving shaft 6 of the CVT can be the engine power output shaft, and the structure of the CVT will not be repeated here. As shown in the figure, the engine 1 Power is output through the crankshaft in the crankcase 17, and the power output shaft section extends out of the crankcase 17 to form the CVT drive shaft 6. The CVT drive shaft 6 is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com