CVT (constant-voltage transformer) transmission structure assembly and motorcycle

A technology of transmission structure and assembly, applied in the direction of wheel transmission, transmission parts, vehicle parts, etc., can solve the problems affecting the long-term operation of the CVT system, the hidden danger of the driving system, and the easy accumulation of heat, so as to ensure the normal long-term Effect of cycle operation, avoidance of heat build-up, compact installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

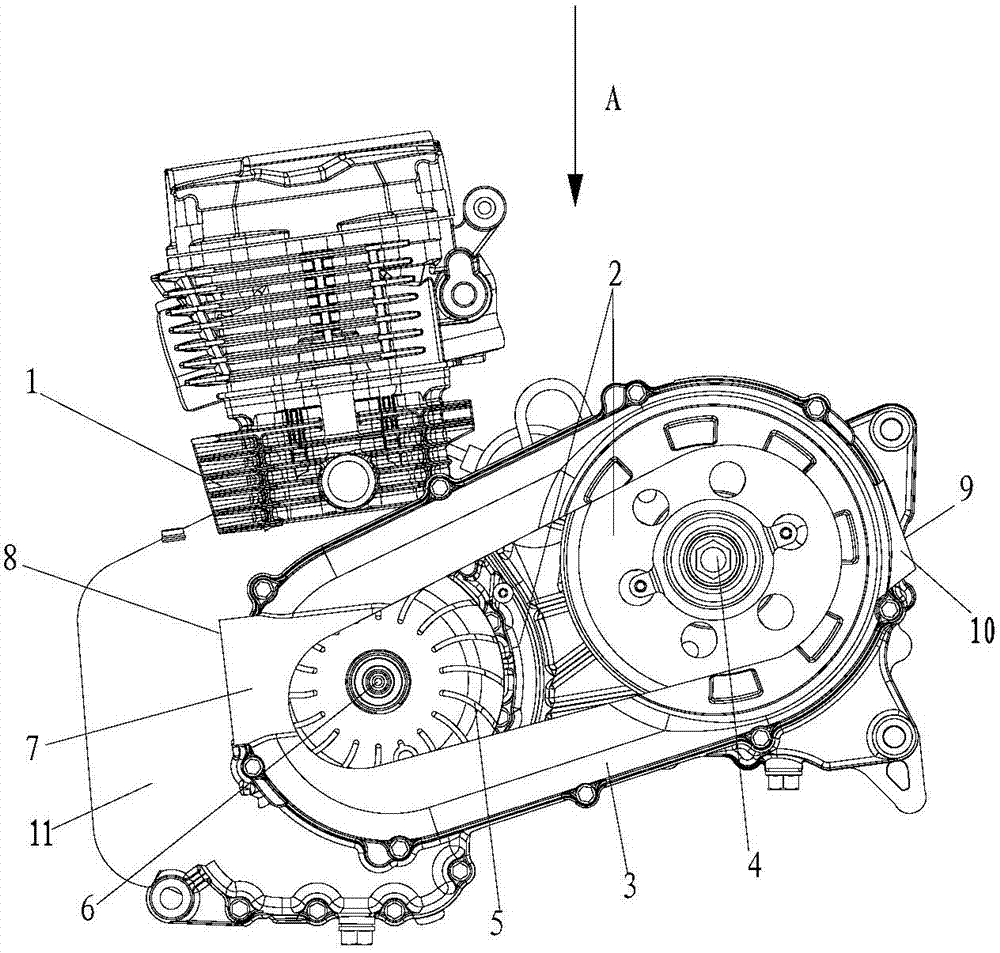

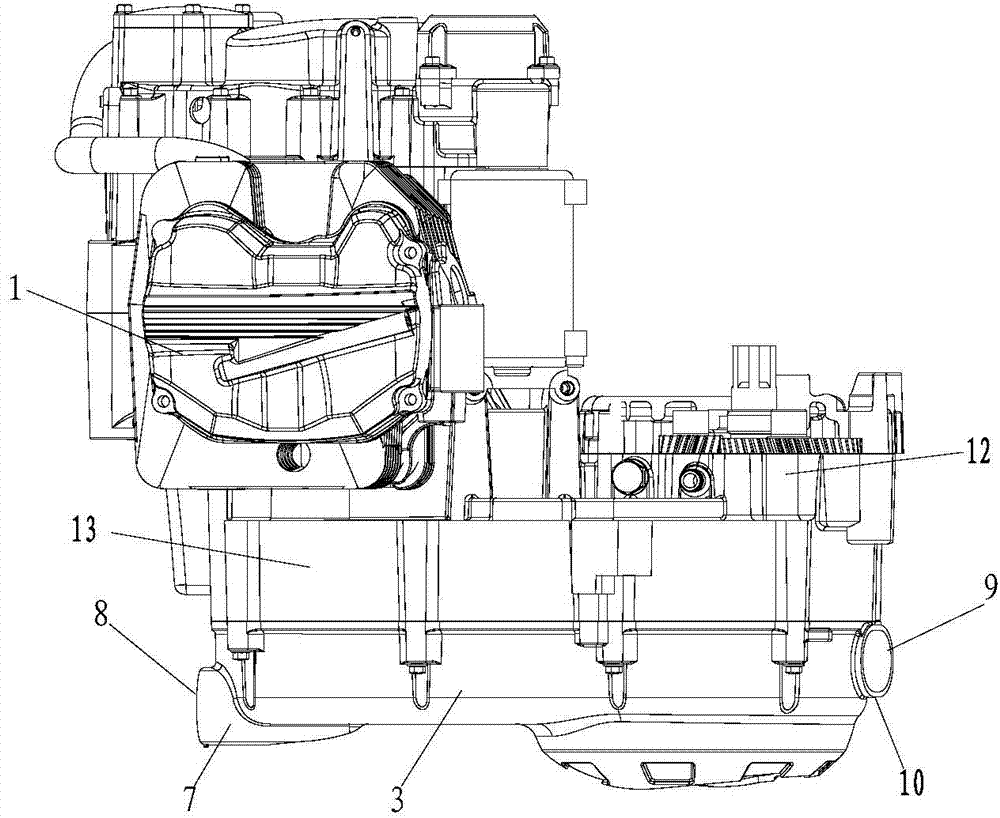

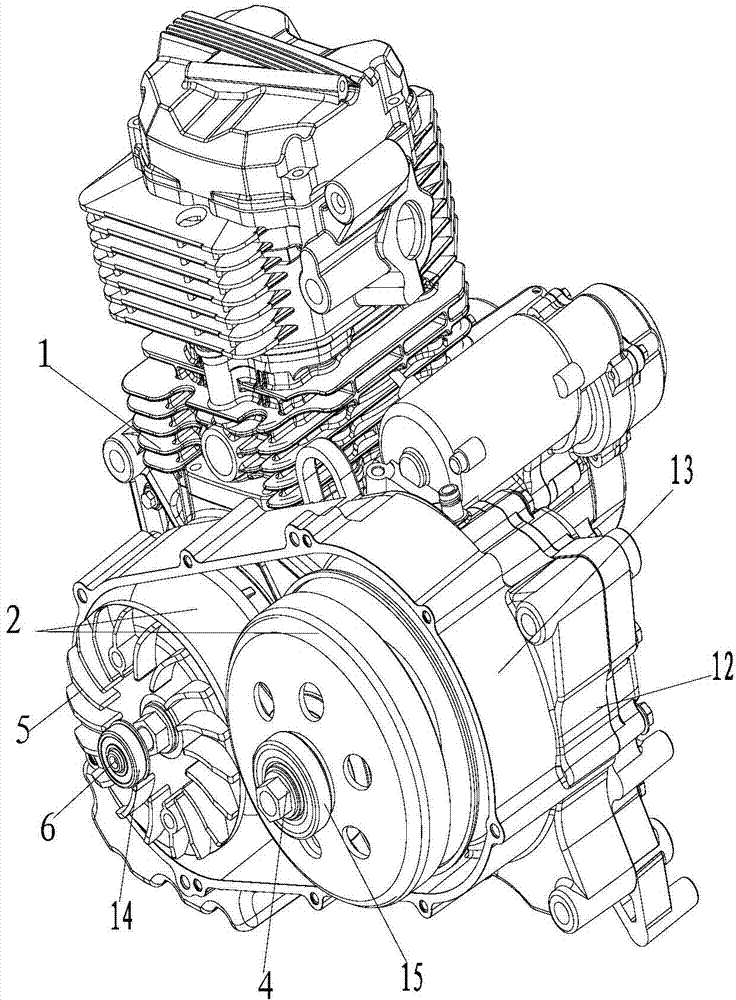

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, image 3 It is a three-dimensional structural schematic diagram of the present invention (with the side end cover removed), as shown in the figure: the CVT transmission structure assembly of this embodiment includes a CVT2 housing and a driving wheel group and a driven wheel group located in the CVT2 housing, and the CVT2 The longitudinal ends of the housing are respectively provided with an air inlet 8 and an air outlet 9; the structure of the CVT2 (continuously variable transmission) will not be repeated here.

[0021] In the present embodiment, the inner chamber of the CVT housing is inclined upward from the side end of the air inlet 8 to the side end of the air outlet 9; the inclined setting is conducive to realizing the principle of gas convection in the inner chamber of the CVT housing. , so that the cooling channel can dissipate heat smoothly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com