Treatment method of habitable room water feed and drainage pipeline fence

A treatment method and technology for water pipelines, applied in vertical pipelines, building components, grinders, etc., can solve the problems of unrecoverable maintenance, long construction period, waste of limited use space, etc., and achieve convenient multiple maintenance and maintenance. The effect of restoration, high construction accuracy, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

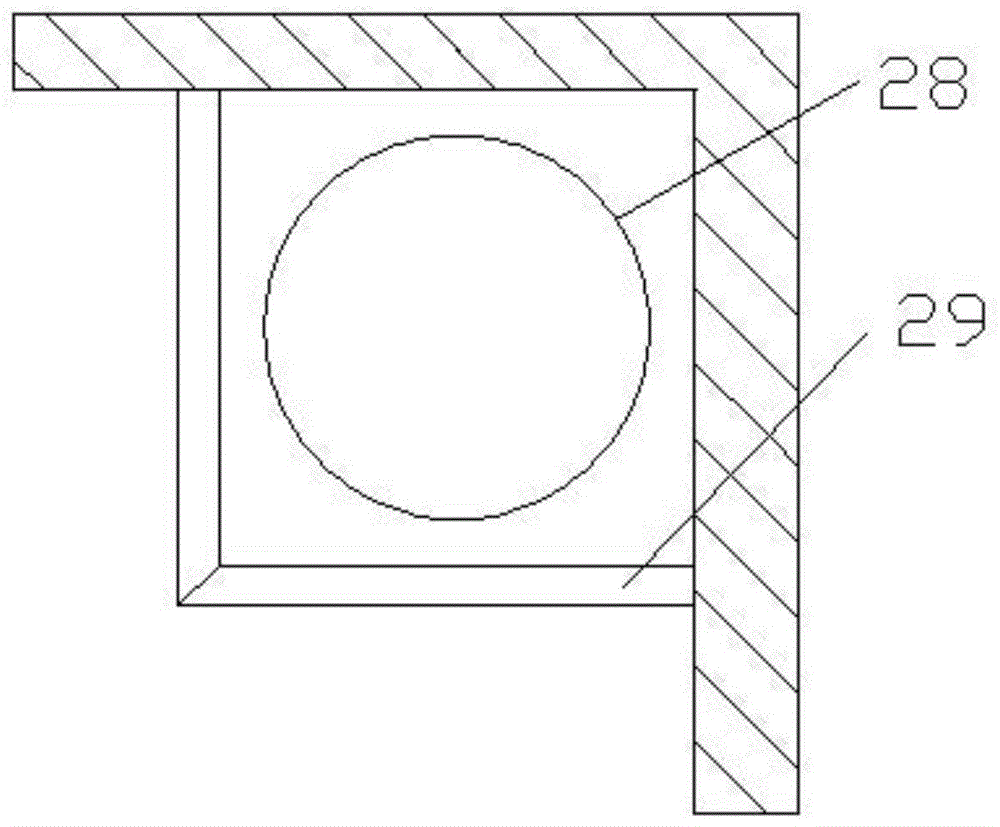

[0027] Specific embodiment 1, such as Figure 1 to Figure 3 As shown, the key to the treatment method for the enclosure of the upper and lower water pipes in the living room is to include the following steps:

[0028] A. Measure the size of the location where tiles need to be installed on the outside of the upper and lower water pipes, and record the size data of the upper and lower water pipes;

[0029] B. Purchasing tiles for cutting, according to the size data of the upper and lower water pipes in step A, use the angle grinder to cut the tiles, and select the tiles to be chamfered;

[0030] C. Use the grinding device for tile chamfering to chamfer and polish the tiles to be chamfered in step B, add water during the grinding process, and the grinding angle is 45°, and use the heating tube to heat the surface of the tiles at a temperature of 70-80°C moisture drying;

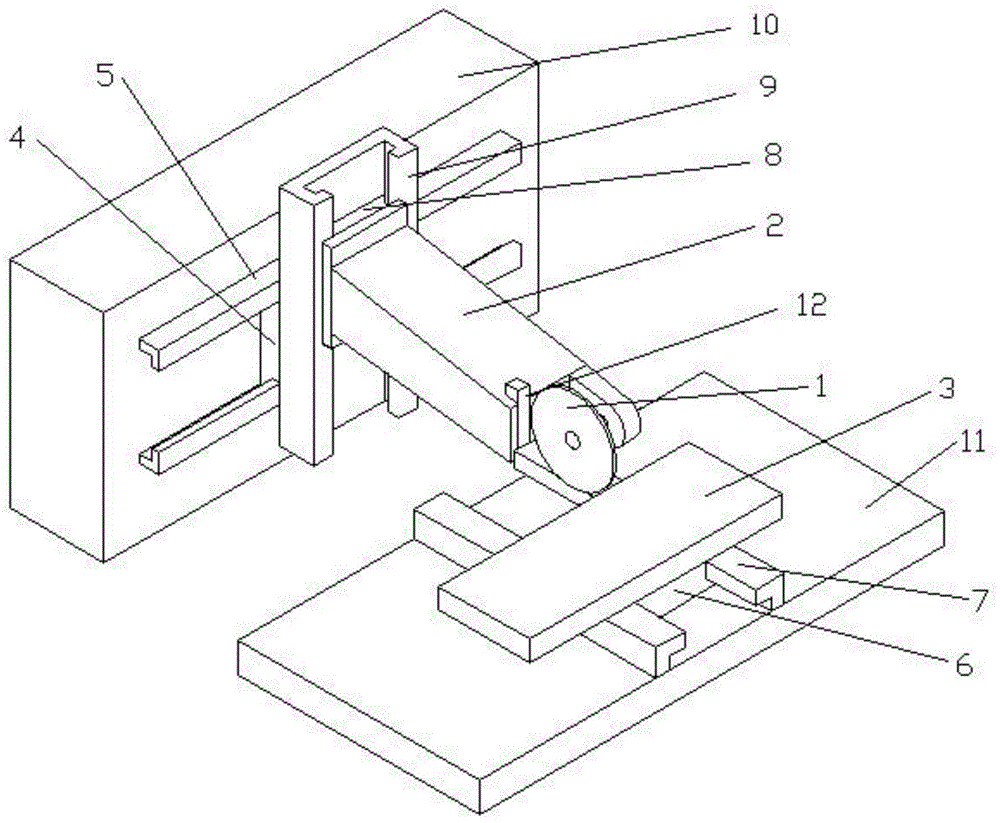

[0031] The grinding device for tile chamfering described in step C includes a grinding sheet 1, and also in...

Embodiment 1

[0035] The width of tiles to be chamfered by the enclosing blocks of pipe diameters of various sizes in embodiment 1, the table is as follows:

[0036] The outer diameter of the upper and lower water pipes

specific Embodiment 2

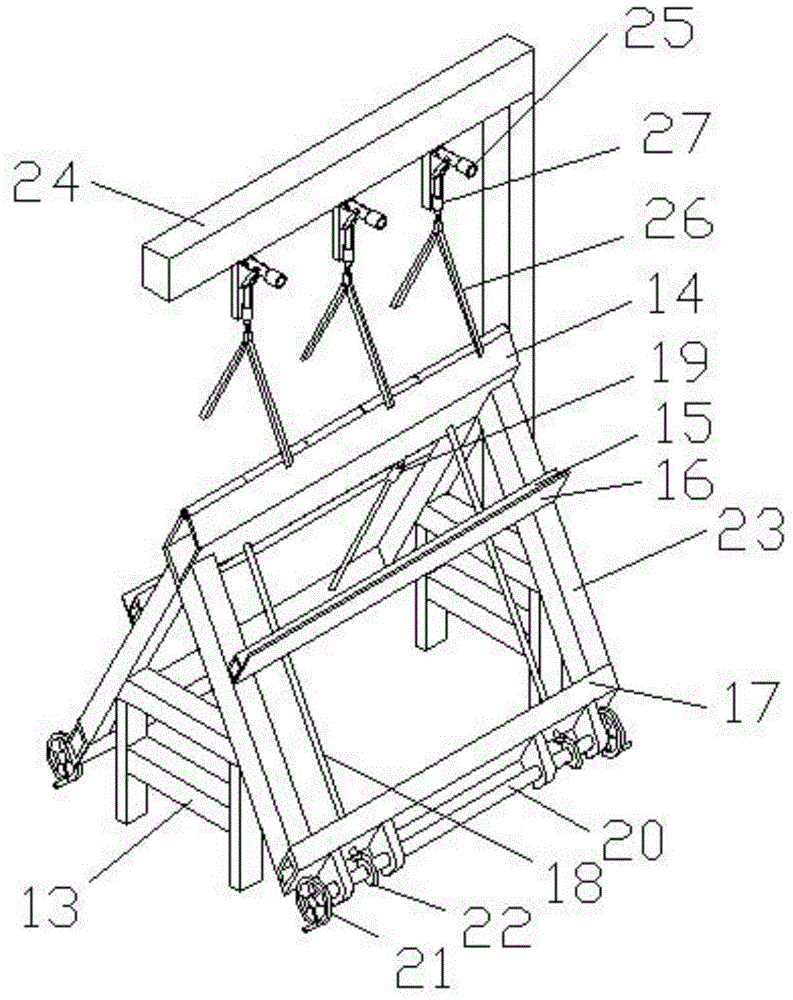

[0037] Specific embodiment 2, such as figure 1 , figure 2 and Figure 4 As shown, the key to the treatment method for the enclosure of the upper and lower water pipes in the living room is to include the following steps:

[0038] A. Measure the size of the location where tiles need to be installed on the outside of the upper and lower water pipes, and record the size data of the upper and lower water pipes;

[0039] B. Purchasing tiles for cutting, according to the size data of the upper and lower water pipes in step A, use the angle grinder to cut the tiles, and select the tiles to be chamfered;

[0040] C. Use the grinding device for tile chamfering to chamfer and polish the tiles to be chamfered in step B, add water during the grinding process, and the grinding angle is 45°, and use the heating tube to heat the surface of the tiles at a temperature of 70-80°C moisture drying;

[0041] D. Splice the chamfered tiles polished in step C, use glass glue or marble glue to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com