Capacitor platform for series compensator

A capacitor and capacitor bank technology, which is applied in circuit devices, substations/switchgear boards/panels/desks, electrical components, etc., can solve the problem that the platform layout of 1000kV/750kV capacitors cannot achieve the expected effect, and the installation technology and installation process requirements are relatively high. High, the capacity of the damping device is increased, etc., to achieve the effect of reasonable structure, balanced force, and compact layout of the layout plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

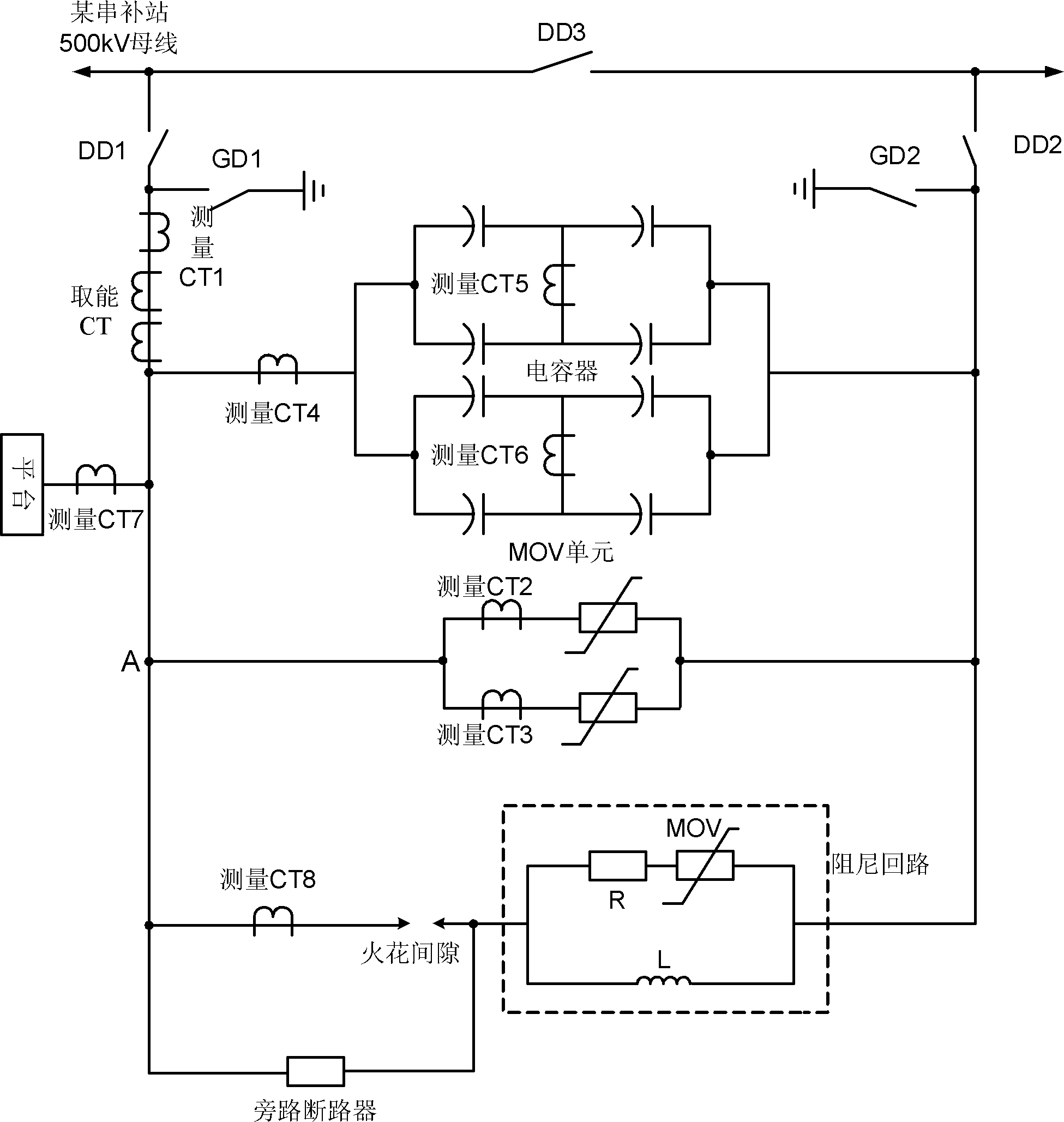

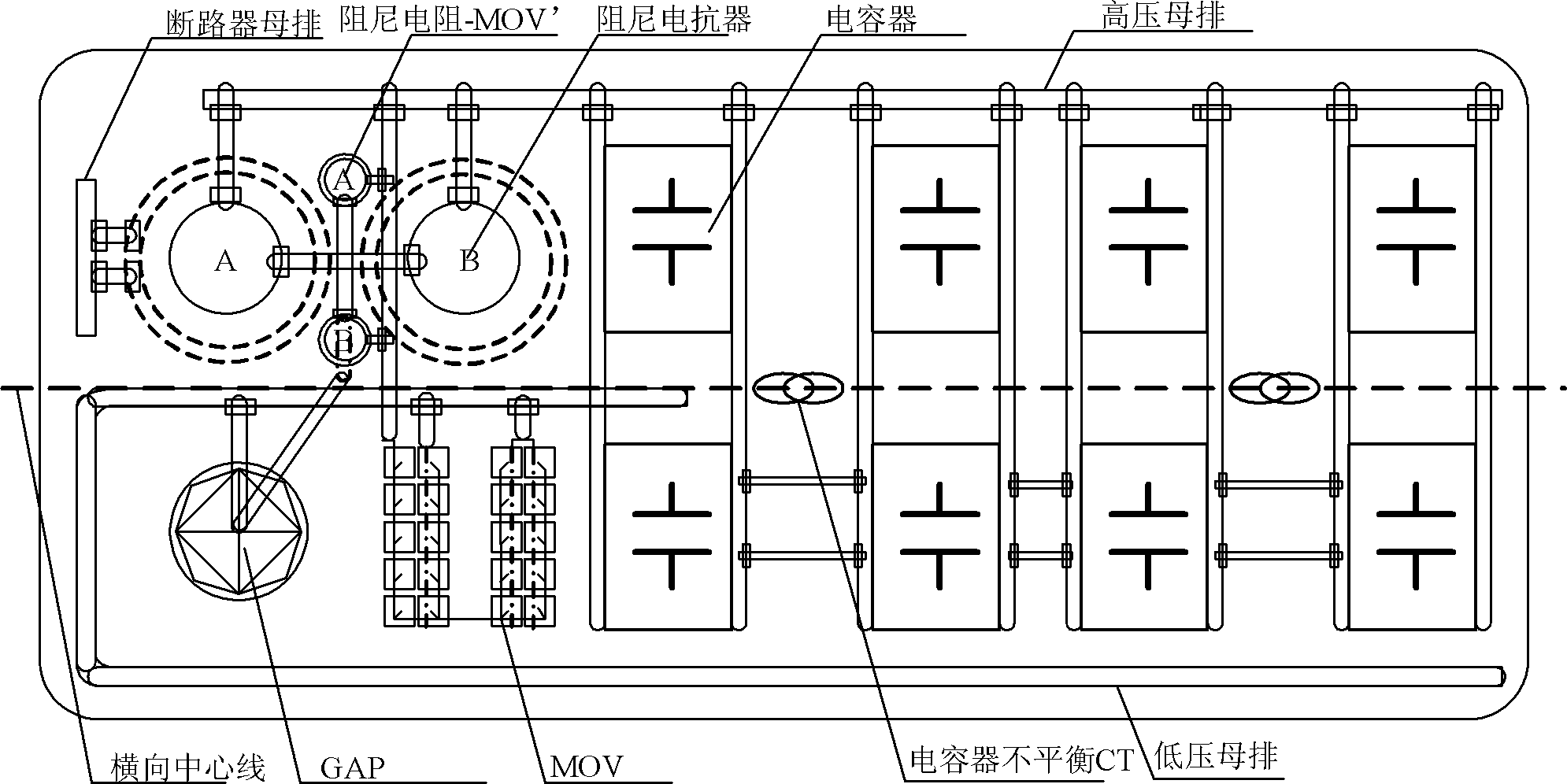

[0036] figure 1 The fixed series compensation single-phase schematic diagram using double H-bridge wiring for the capacitor bank, the top view of the platform layout is as follows figure 2 As shown in the figure, the outermost black rectangle with rounded corners represents the steel structure capacitor platform of the series compensation device. Among them, the double lines located on the edge of the long side of the platform are busbars. Among them, the busbars above the platform are arranged in a straight line, and the busbars are high-voltage busbars. Extend to the middle of the left short side of the platform and then extend to the horizontal centerline of the platform until the middle of the bridge arm of the capacitor bank placed on the far left. This busbar is a low-voltage busbar; there is a section on the upper half of the left short side of the platform for connecting the series compensation device The busbar of the bypass circuit breaker, this busbar is the circu...

Embodiment 2

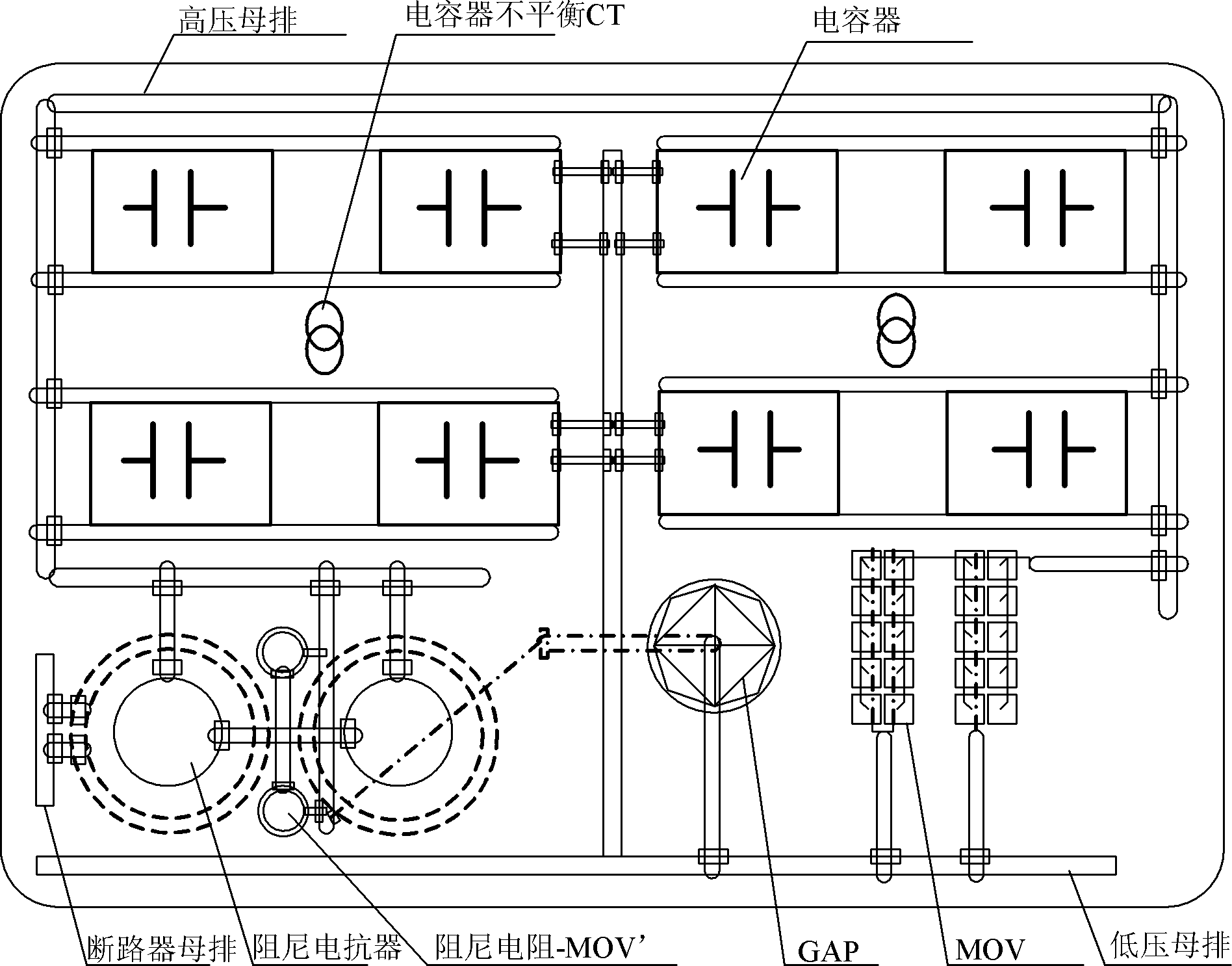

[0041] Taking the fixed series capacitor compensation device with double H-bridge connection as an example for the capacitor bank, the specific implementation method of the capacitor platform layout scheme 2 will be described in detail below:

[0042] The top view of the series compensation capacitor platform of Scheme 2 is as follows: image 3 As shown, among them, the difference from scheme 1 is:

[0043] The low-voltage busbars are arranged on the capacitor platform in an inverted T shape; the high-voltage busbars are arranged on the capacitor platform in the shape of a cover with hooks; the capacitor banks connected by double H bridges are arranged symmetrically on both sides of the inverted T-shaped low-voltage busbars; One end of the group is connected to the high-voltage busbar, and the other end is connected to the low-voltage busbar.

[0044] The damping device is arranged between the high-voltage busbar and the low-voltage busbar on the horizontal center line, on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com