Frictional resistance noise elimination device of windshield wiper

A friction resistance and noise elimination technology, applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve problems such as wear, shorten the service life of wipers, and cannot improve resistance and friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Cooperate with drawing and will enumerate preferred embodiment hereby, the content of the present invention in detail is as follows:

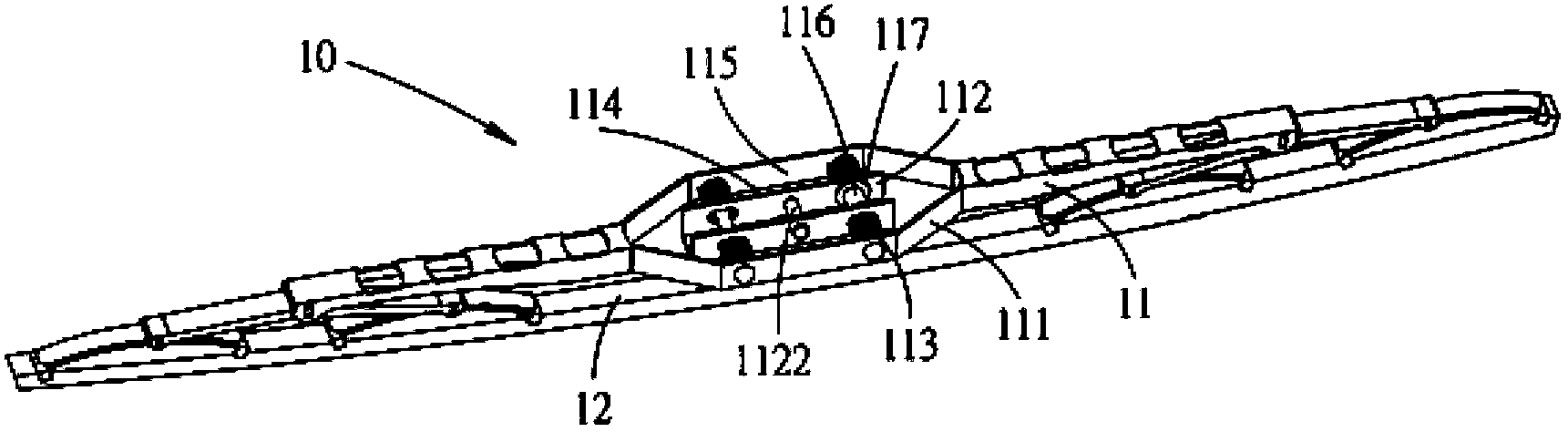

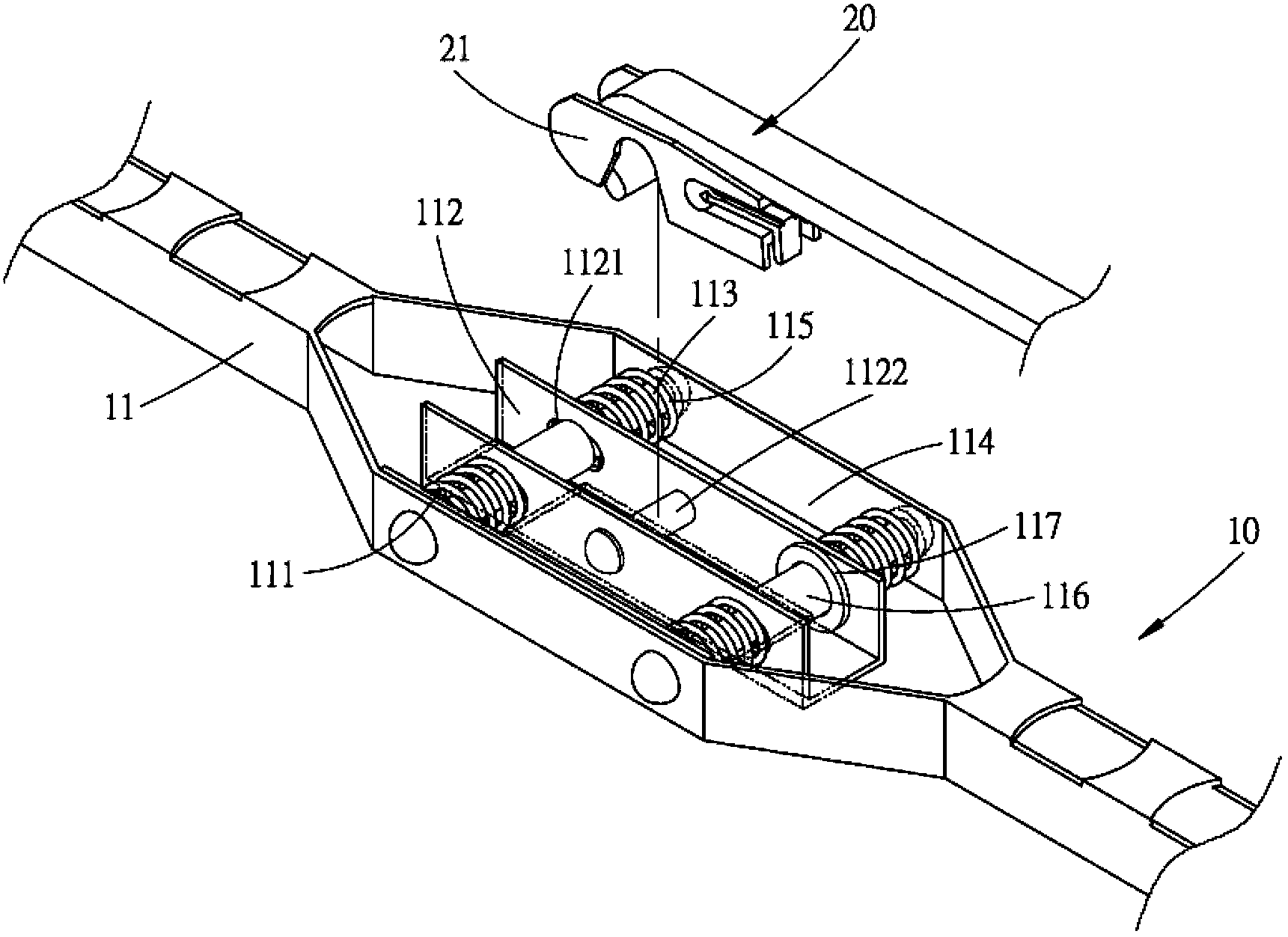

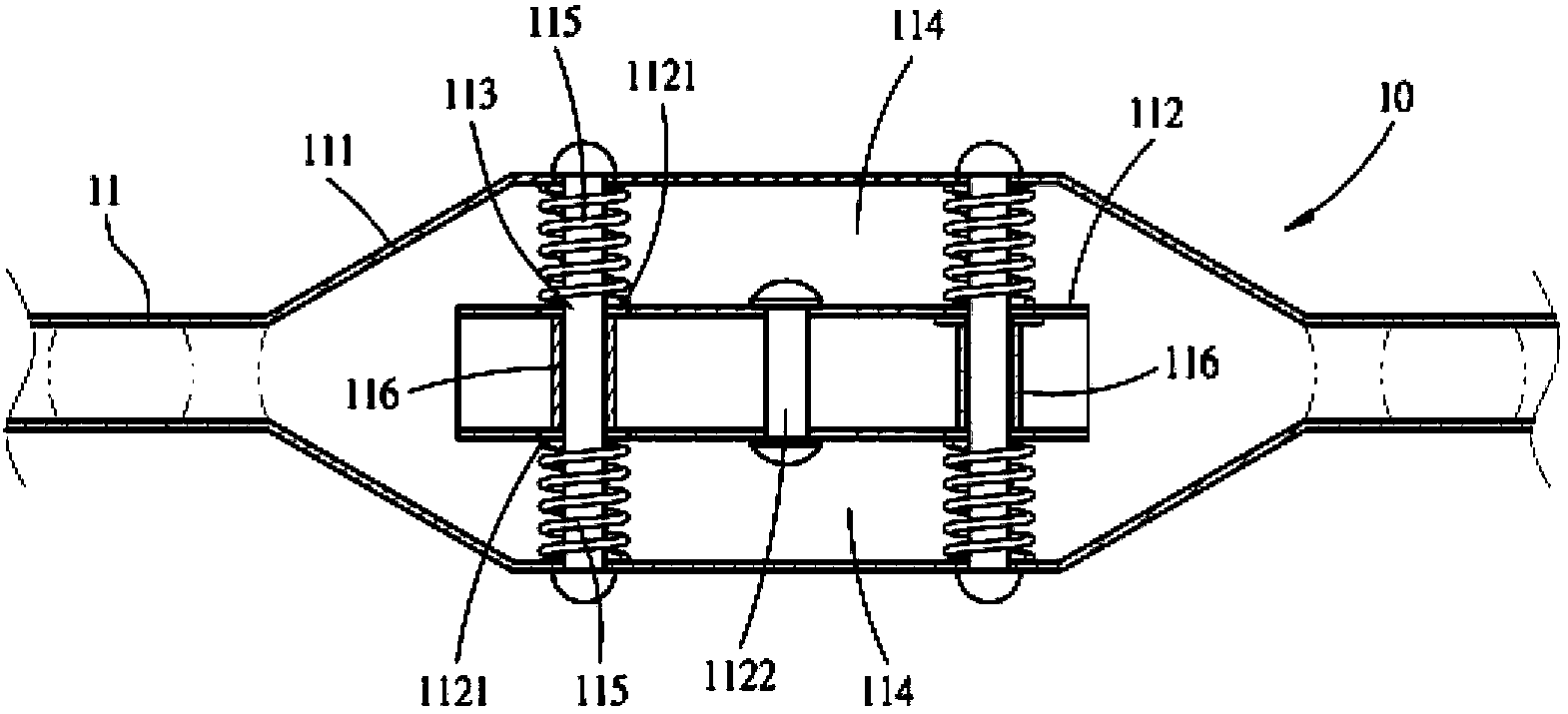

[0033] Such as figure 1 Shown is the combination stereogram of the present invention (please refer to simultaneously Figure 2-6 As shown), the wiper 10 is assembled with the connector 21 of the wiper arm 20, including: a main frame 11, an elastic bead scraper 12, wherein the main frame 11 is expanded in the center with a vertical wall on both sides and the main frame 11 The hollow pivotal wall 111 connected by the sides is extended in the center of the pivotal wall 111, and a U-shaped groove movable seat 112 is connected with a buckle type or a locking type connector 1122 in the middle, and the movable seat 112 is on the two long sides. Two pairs of corresponding oval-shaped lateral actuation holes 1121 are opened on the wall toward the appropriate positions on both sides of the connecting piece 1122, and two pairs of actuation holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com