A kind of preparation method of composite calcium carbonate

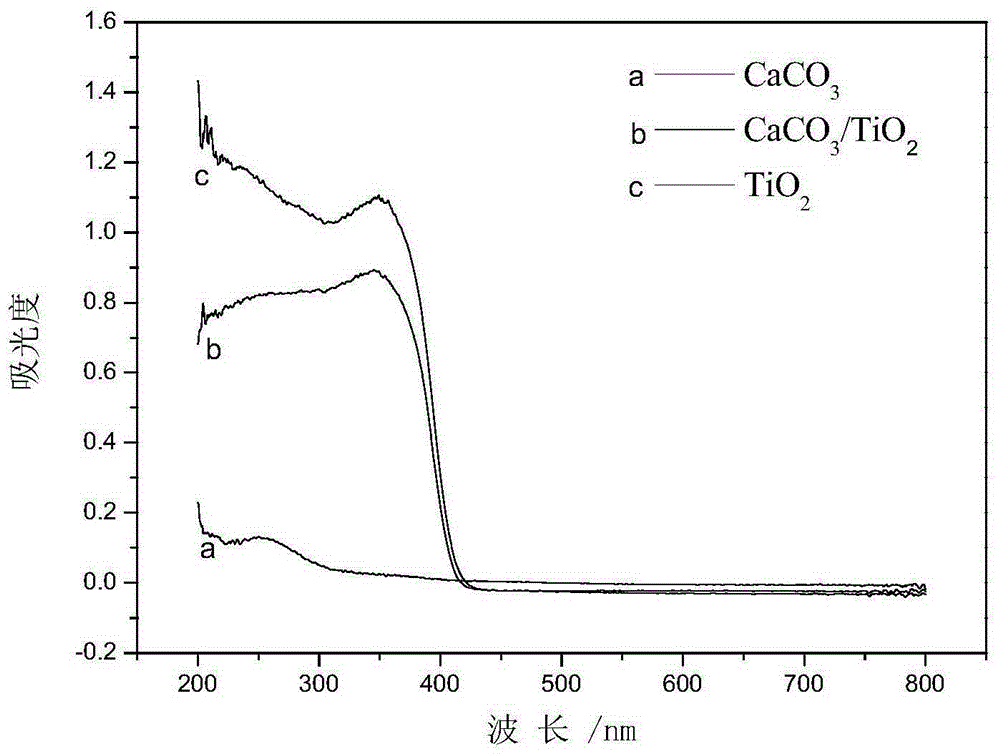

A technology of compounding calcium carbonate and calcium hydroxide, which is applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous fillers, etc., can solve the problems of low coating rate, easy peeling, and difference in coating rate of titanium dioxide , to achieve the effects of simple production process, improved hiding power, and high UV absorption intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Under the conditions of 40°C and a stirring speed of 800 rpm, add 7.4% rutile titanium dioxide and 0.074% polyethylene glycol or polyethylene two to the calcium hydroxide slurry with a mass fraction of 10%. Alcohol ester (molecular weight 1000), mechanically stirred for 30 minutes, and then at a rate of 120 liters / minute, a mixture of carbon dioxide and nitrogen in a volume ratio of 1:2 is introduced for carbonization reaction. When the pH of the solution is 7, the reaction is stopped. A white water slurry is obtained; the white water slurry is subjected to centrifugal dehydration and dried at 120°C for 4 hours.

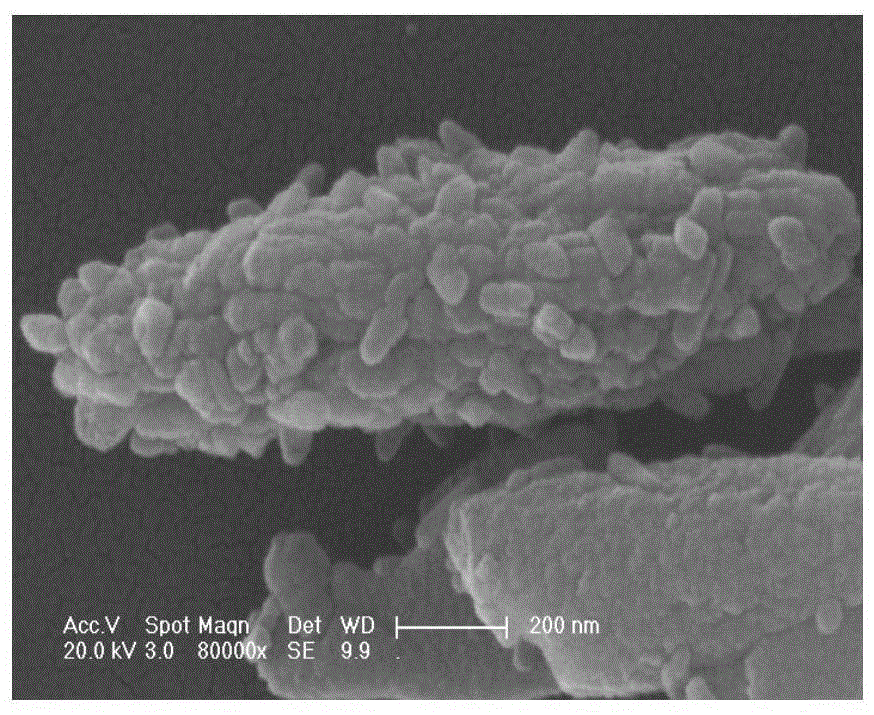

[0018] The whiteness value of composite calcium carbonate is 96.3, the yield is 97%, and the coating rate of calcium carbonate is 94%. When observing the composite calcium carbonate with a scanning electron microscope, rutile titanium dioxide is coated on the surface of the calcium carbonate, and there is no separate titanium dioxide.

Embodiment 2

[0020] Under the conditions of 50°C and stirring speed of 800 rpm, add 11.1% of the calcium hydroxide mass and 0.296% of polyethylene glycol or polyethylene to the calcium hydroxide slurry with a mass fraction of 10%. Alcohol ester (molecular weight 2000), mechanically stirred for 40 minutes, and then at a rate of 90 liters / minute, a mixed gas of carbon dioxide and nitrogen with a volume ratio of 1:2 is introduced for carbonation reaction. When the pH of the reaction solution is 7, stop After the reaction, a white water slurry was obtained; the white water slurry was subjected to centrifugal dehydration, and then dried at 120°C for 4 hours.

[0021] The whiteness value of the composite calcium carbonate is 97.2, the yield is 98%, and the coating rate of calcium carbonate is 96%. When observing the composite calcium carbonate with a scanning electron microscope, rutile titanium dioxide is coated on the surface of the calcium carbonate, and there is no separate titanium dioxide.

Embodiment 3

[0023] Under the conditions of 50℃ and 900 rpm stirring speed, add 14.8% rutile titanium dioxide and 0.518% polyethylene glycol or polyethylene two to the calcium hydroxide slurry with a mass fraction of 15%. Alcohol ester (molecular weight 6000), mechanically stirred for 50 minutes, and then at a rate of 80 liters / minute, a mixture of carbon dioxide and nitrogen with a volume of 1:2 is introduced to carry out the carbonation reaction. When the pH of the reaction solution is 7, stop The reaction yields a white water slurry; the white slurry is subjected to centrifugal dehydration, and then dried at 120°C for 4 hours.

[0024] The whiteness value of the composite calcium carbonate is 96.8, the yield is 97%, and the coating rate of calcium carbonate is 94%. When observing the composite calcium carbonate with a scanning electron microscope, rutile titanium dioxide is coated on the surface of the calcium carbonate, and there is no separate titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com