An up-conversion luminescent material doped with erbium dichloride and its preparation, use and application

A technology of erbium barium dichloride and luminescent materials, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve problems such as difficulty in functioning, meet the requirements of reducing light source power density, and reduce energy level difference mismatch , The effect of improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

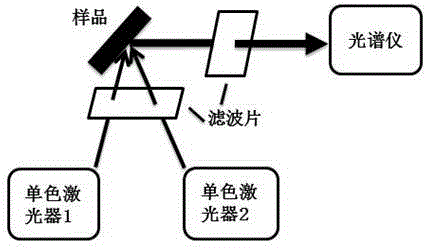

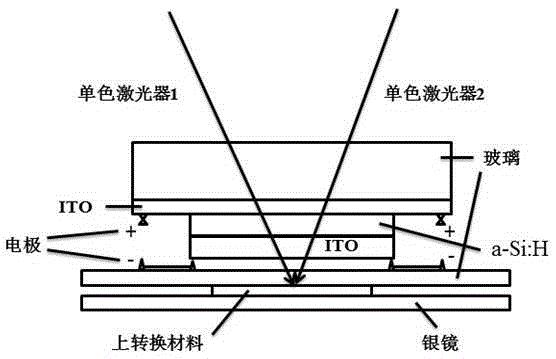

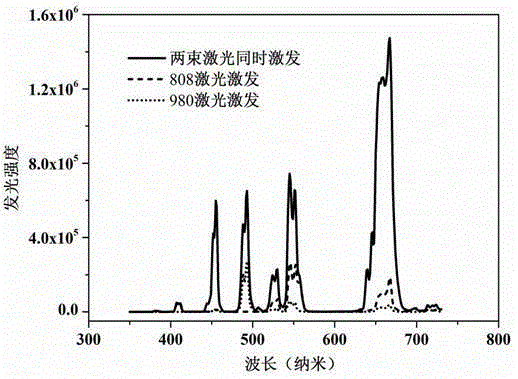

[0025] The molar ratio of barium dichloride and erbium trichloride is 72:28, and the ammonium chloride is 24 times the total molar number of barium dichloride and erbium trichloride for raw material weighing. The ammonium chloride was divided into three equal parts, the first part was placed on the bottom of the crucible, and the second part was mixed with barium dichloride and erbium trichloride by grinding and mixing with an agate mortar in a nitrogen-filled glove box. Evenly put it on the first part, and then spread the last part of ammonium chloride on the second part of the mixture of ammonium chloride, barium dichloride and erbium trichloride. Move the crucible with the above mixture into the corundum ark, then put the corundum ark into a high-temperature tubular atmosphere furnace, pass it into an argon atmosphere for protection, and keep it at 950°C for 1 hour to prepare the up-conversion luminescent material. Simultaneously irradiate the sample with 808nm (monochromat...

Embodiment 2

[0027] The molar ratio of barium dichloride and erbium trichloride is 80:20, and the ammonium chloride is 20 times the total molar number of barium dichloride and erbium trichloride for raw material weighing. The ammonium chloride was divided into three equal parts, the first part was placed on the bottom of the crucible, and the second part was mixed with barium dichloride and erbium trichloride by grinding and mixing with an agate mortar in a nitrogen-filled glove box. Evenly put it on the first part, and then spread the last part of ammonium chloride on the second part of the mixture of ammonium chloride, barium dichloride and erbium trichloride. Move the crucible with the above mixture into the corundum ark, then put the corundum ark into a high-temperature tubular atmosphere furnace, pass it into an argon atmosphere for protection, and keep it at 800°C for 3 hours to prepare the up-conversion luminescent material. Simultaneously irradiate the sample with 800nm (monochro...

Embodiment 3

[0029] The molar ratio of barium dichloride and erbium trichloride is 65:35, and the ammonium chloride is 30 times the total molar number of barium dichloride and erbium trichloride for raw material weighing. The ammonium chloride was divided into three equal parts, the first part was placed on the bottom of the crucible, and the second part was mixed with barium dichloride and erbium trichloride by grinding and mixing with an agate mortar in a nitrogen-filled glove box. Evenly put it on the first part, and then spread the last part of ammonium chloride on the second part of the mixture of ammonium chloride, barium dichloride and erbium trichloride. Move the crucible with the above mixture into the corundum ark, then put the corundum ark into a high-temperature tubular atmosphere furnace, pass it into an argon atmosphere for protection, and keep it at 1100°C for 2 hours to prepare the up-conversion luminescent material. Simultaneously irradiate the sample with 808nm (monochrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com