Auxiliary device for secondary cable plugging

A technology for secondary cables and auxiliary devices, which is applied in the direction of electrical components, pipes, pipes/pipe joints/fittings, etc., and can solve the problems of fireproof mud falling, poor cable sealing effect, and difficult filling of secondary cable gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below:

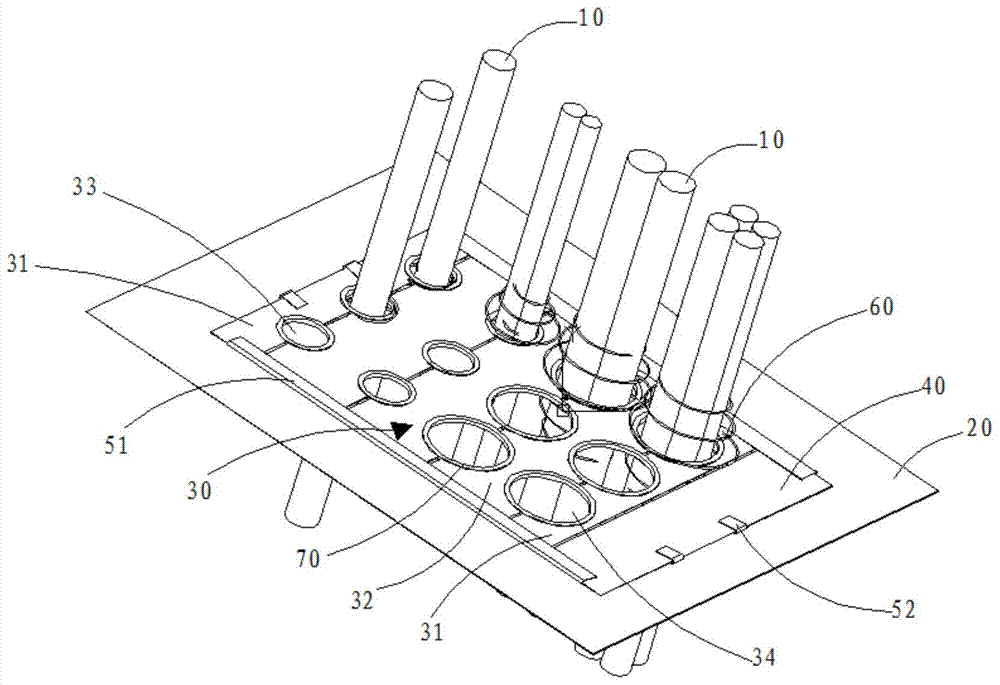

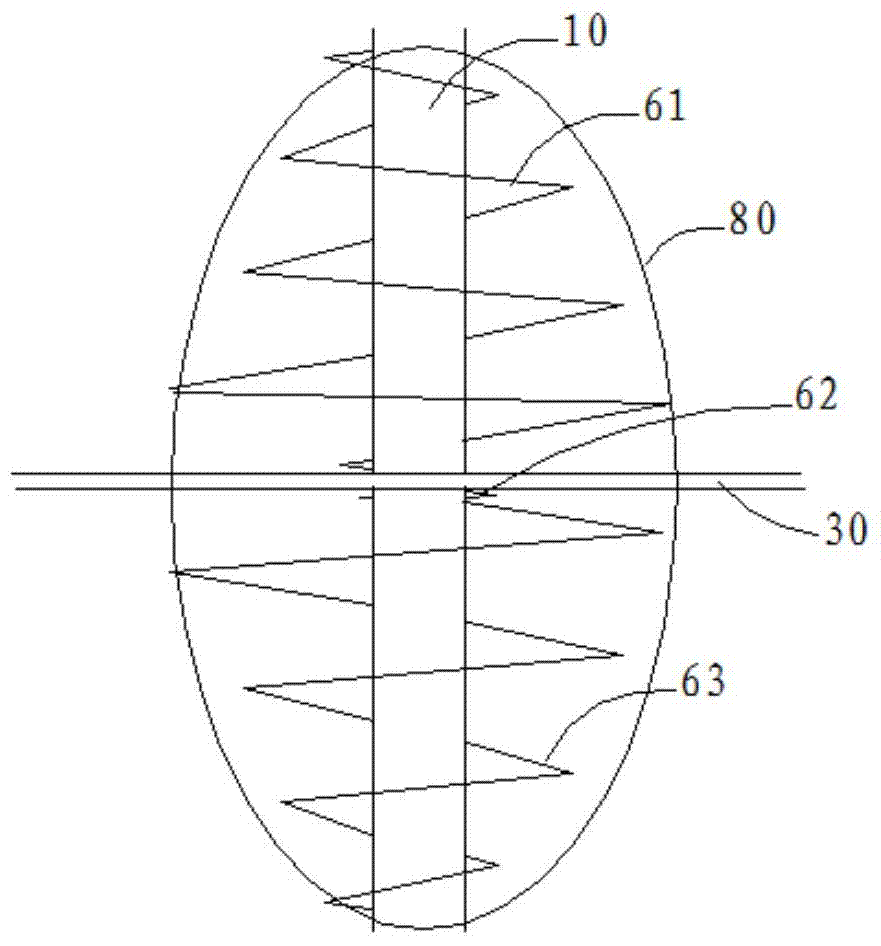

[0036] Such as figure 1 and figure 2 As shown, an auxiliary device for secondary cable plugging according to the present invention includes a panel 30, and the panel 30 has one or more installation holes, and each installation hole is spirally wound with a spiral coil portion 60 , the spiral coiled part 60 is wound outside the secondary cable 10, and the secondary cable 10 is coated with fireproof mud 80, and the fireproof 80 mud is wrapped around the spiral coiled part 60 and sealed with the installation hole connect. In the embodiment of the present invention, the helical winding part 60 is made of steel wire.

[0037] The panel 30 described in the present invention that is used for the secondary cable plugging auxiliary device is installed at the plugging opening of the cabinet panel 20, and the secondary cables in the cabinet are first divided into several parts, and then pass through the pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com