Automatic deviation rectification control method for pipeline cleaning device

A pipeline cleaning and automatic deviation correction technology, which is applied to special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve problems such as difficult operation and low cleaning efficiency, achieve standard deviation correction actions, improve work efficiency, and speed up deviation correction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

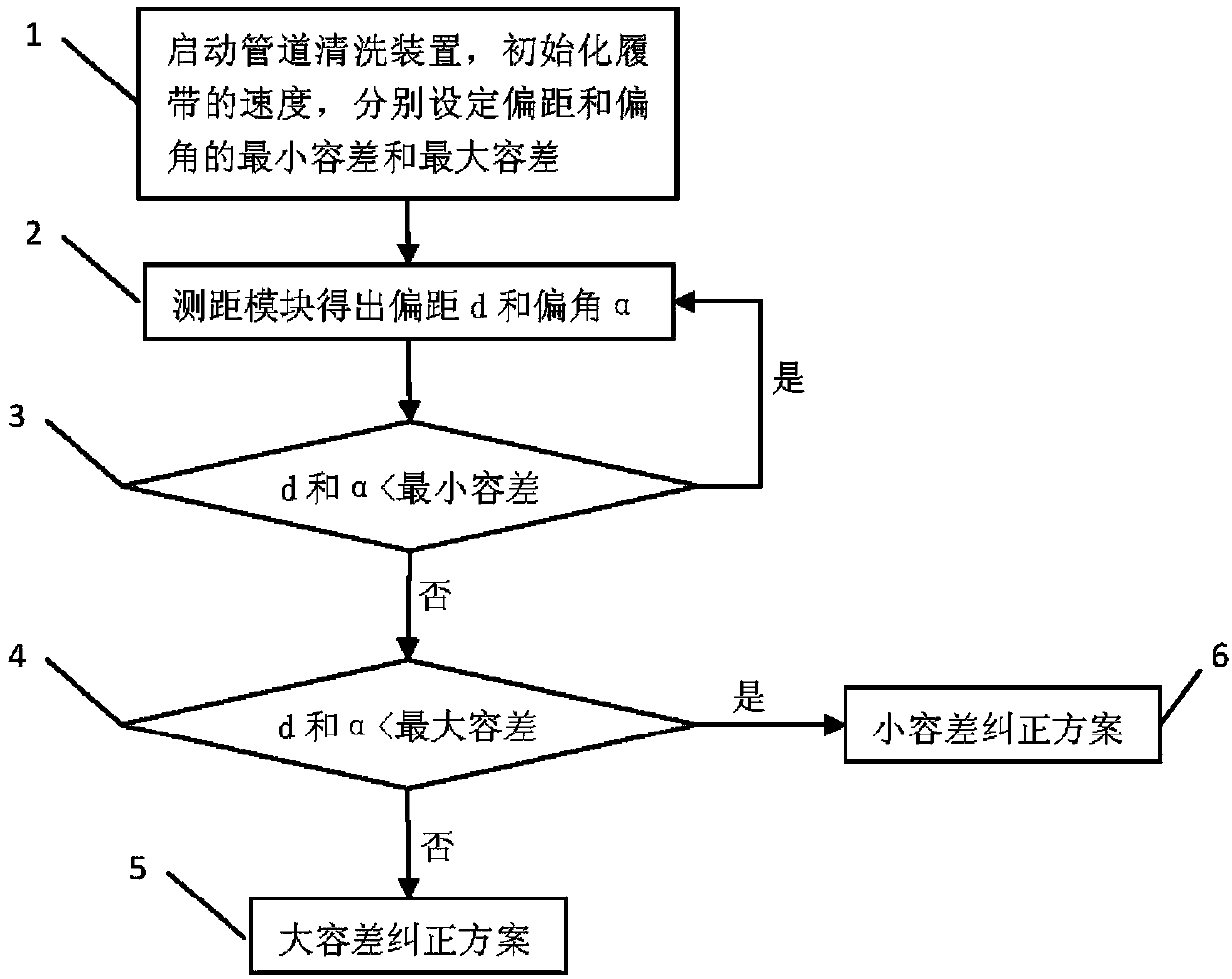

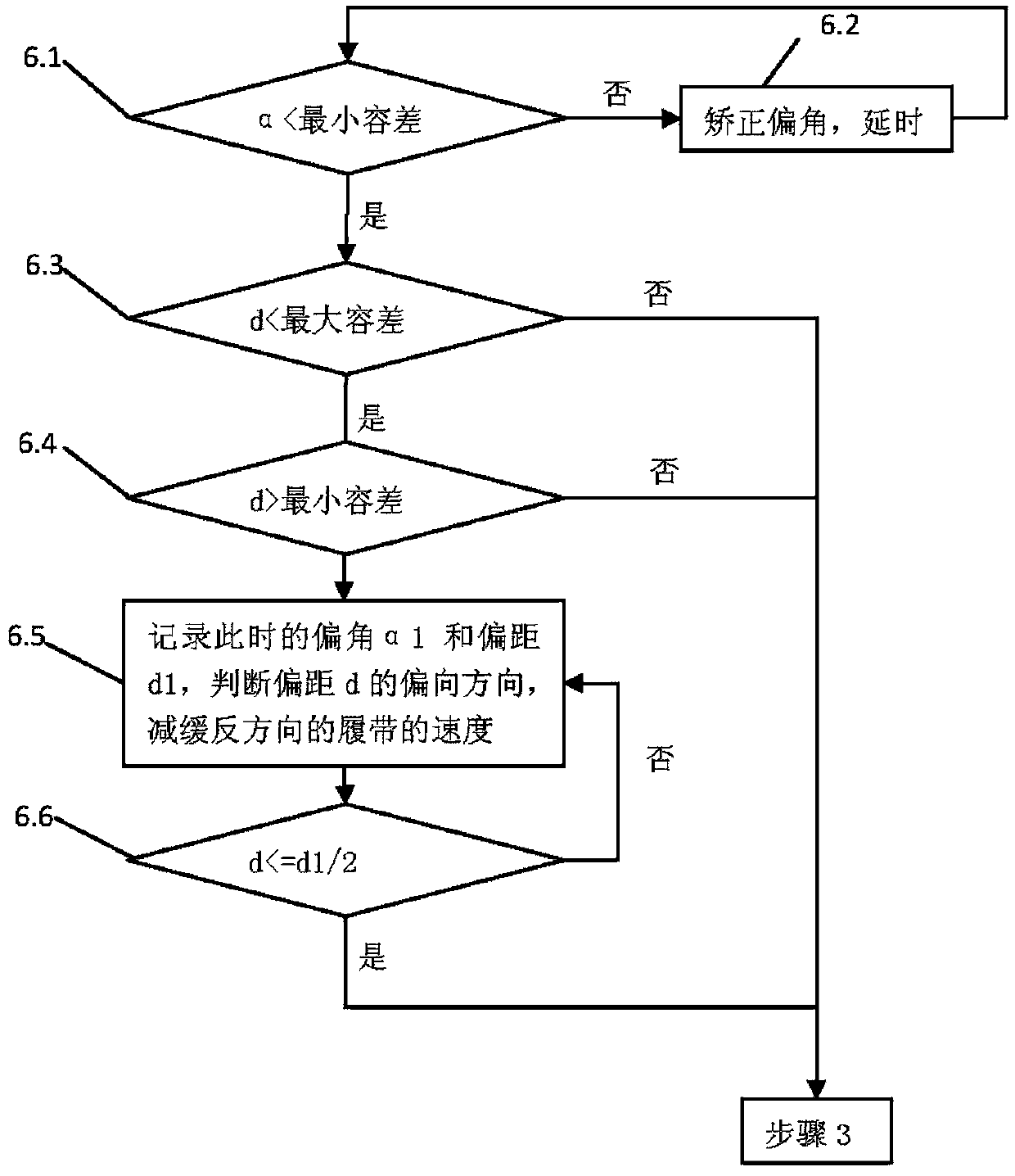

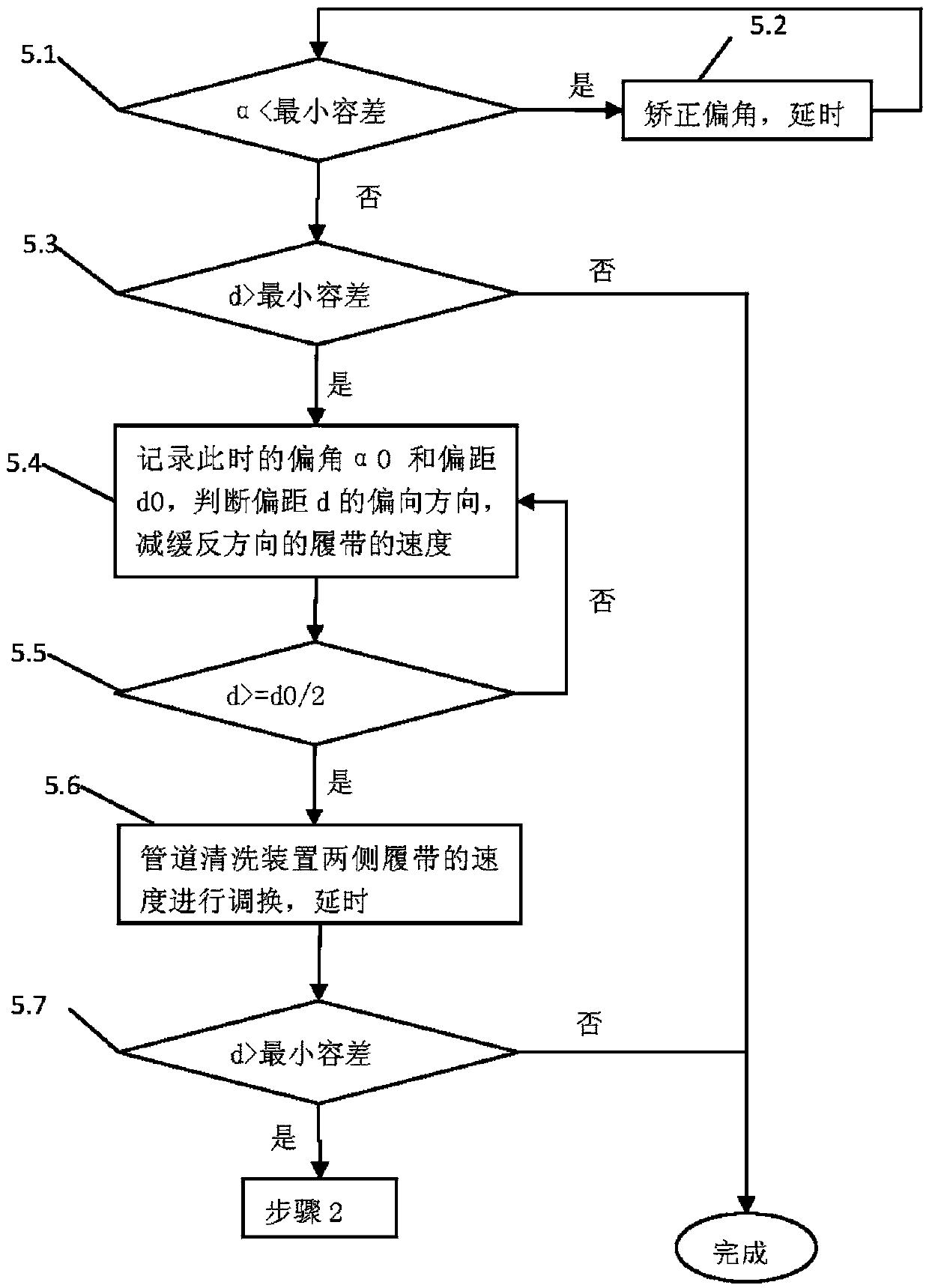

[0017] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the descriptions of the specific embodiments are only used to explain the technical solutions proposed by the present invention, not to limit the present invention.

[0018] The ranging module of the present invention adopts two laser ranging sensors, which are respectively installed at the front end and the rear end of the same side of the pipeline cleaning device. Based on the principle of determining a straight line at two points, and according to the distance information returned by the two sensors and the appropriate sensor installation position information, the offset angle (referred to as the deflection angle α) of the pipeline cleaning device from the central axis of the pipeline during its travel can be calculated. ) and the offset axis distance of the axis center of the pipeline cleaning device (referred to as the offset d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com