Rolling bearing fault diagnosis method based on EEMD and distribution fitting testing

A technology of distribution fitting test and rolling bearing, which is applied in the field of fault diagnosis of rolling bearings based on EEMD and distribution fitting test, can solve problems such as modal aliasing, and achieve the goal of reducing modal aliasing, good theoretical basis, and obvious fault characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

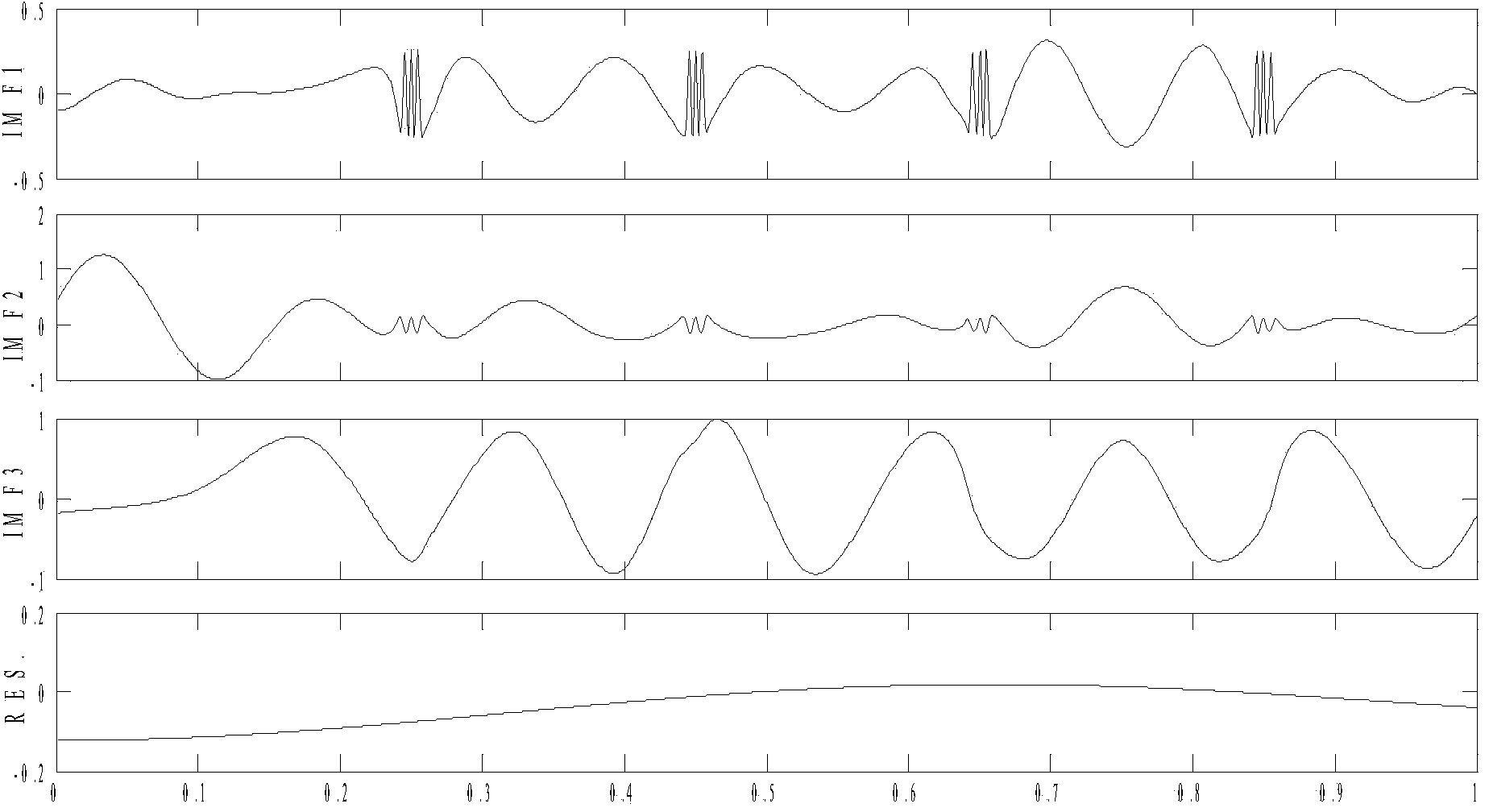

[0025] 1. Assuming a simulation signal s(t), its composition is the superposition of 7Hz sinusoidal component and Gauspuls pulse component, figure 1 is the result of s(t) after EMD decomposition.

[0026] from figure 1 It can be clearly seen that the modal aliasing phenomenon has obviously occurred in IMF1 and IMF2, and it is difficult to see the physical meanings represented by IMF1 and IMF2 from the figure.

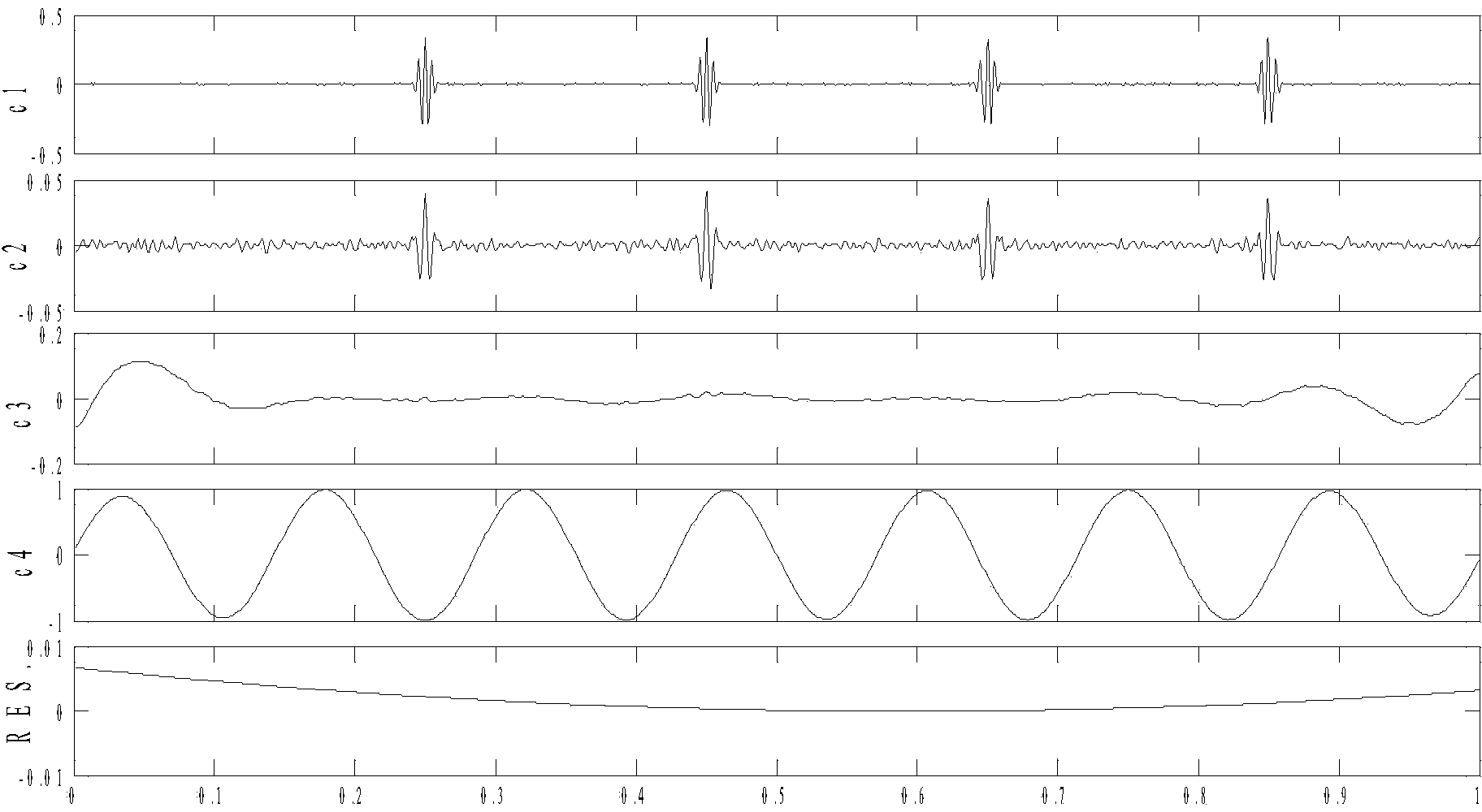

[0027] 2. Perform EEMD decomposition on the simulation signal s(t) in 1, the result is as follows figure 2 shown. from figure 2 It can be seen from s(t) that after EEMD decomposition, 4 IMF components and 1 margin are obtained, where c1 and c2 represent the decomposed Gauspuls pulse components, and c4 well represents the 7Hz sine component. Therefore, after After EEMD decomposition, the components contained in the original signal can be well decomposed, and each IMF component has its own physical meaning. Therefore, EEMD can well solve the problem of mode mixing,...

Embodiment 2

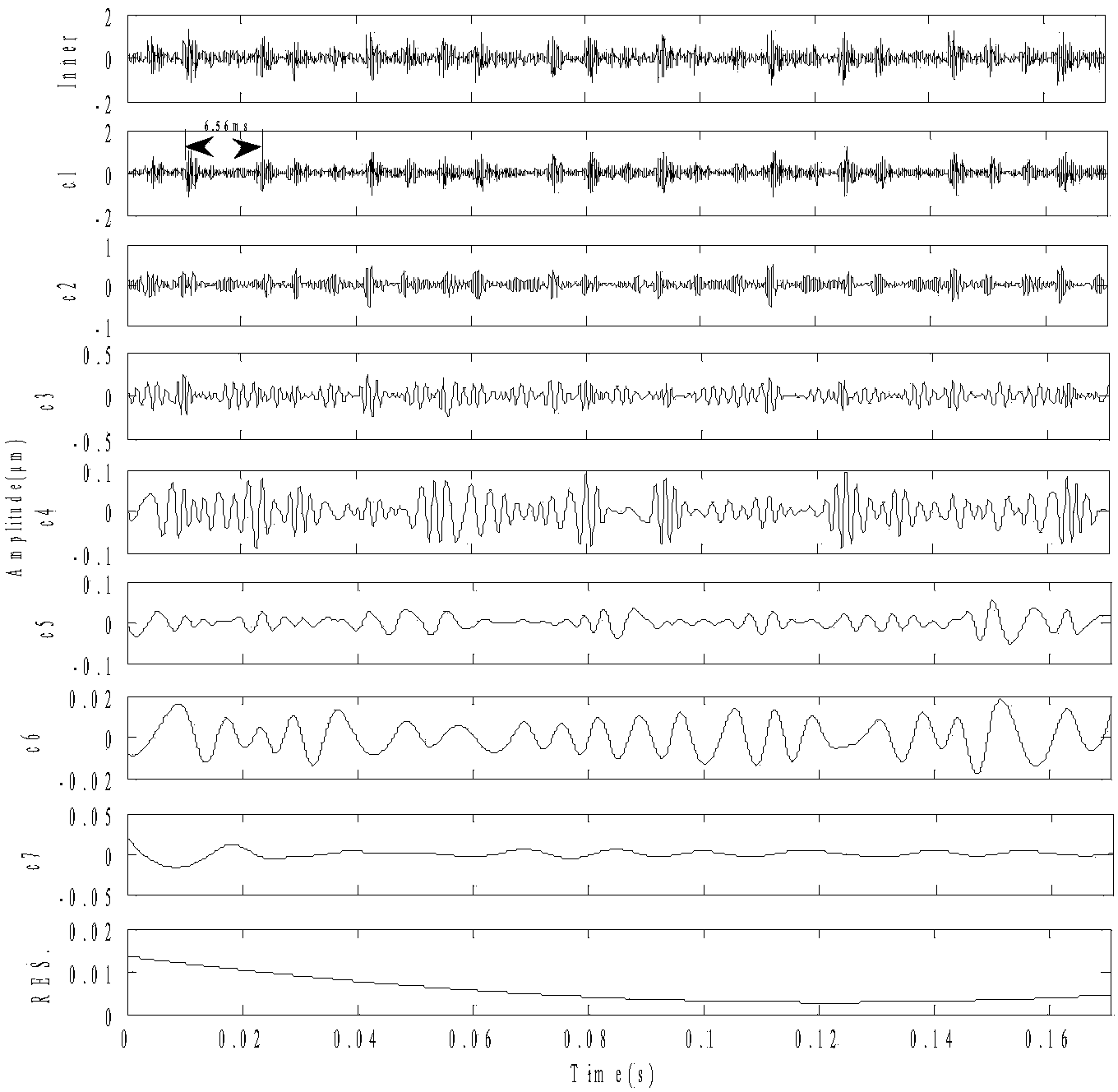

[0029] The fault signal of the inner ring of the rolling bearing comes from the Bearing Data Center of Case Western Reserve University in the United States, where the sampling frequency is 12000Hz and the motor speed is 1750r / min. Firstly, the EEMD decomposition is performed on the fault signal of the inner ring of the rolling bearing, and several intrinsic mode function components are obtained. Then, according to the probability distribution characteristics of IMF components, the selection of useful IMF components and the removal of useless IMF components are carried out by using normal probability graph and Jarque-Bera test method. The useful IMF component is reconstructed to obtain the noise-reduced inner ring fault signal, and finally the characteristic frequency of the rolling bearing fault is identified by using the envelope spectrum.

[0030] image 3 It is the result of the EEMD decomposition of the fault signal of the inner ring of the rolling bearing. Figure 4 Nor...

Embodiment 3

[0036] The fault signal of the rolling bearing outer ring still comes from the Bearing Data Center of Case Western Reserve University in the United States, where the sampling frequency is 12000Hz and the motor speed is 1750r / min. Firstly, the EEMD decomposition is performed on the fault signal of the outer ring of the rolling bearing to obtain several eigenmode function components. Then, according to the probability distribution characteristics of IMF components, the selection of useful IMF components and the removal of useless IMF components are carried out by using normal probability graph and Jarque-Bera test method. The useful IMF component is reconstructed to obtain the noise-reduced outer ring fault signal, and finally the characteristic frequency of the rolling bearing fault is identified by using the envelope spectrum.

[0037] Figure 7 It is the result of the EEMD decomposition of the rolling bearing outer ring fault signal. Figure 8Normal probability plot of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com