Method for measuring material complex permittivity based on substrate integrated waveguide round resonant cavities

A substrate-integrated waveguide and complex permittivity technology, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as inaccurate measurement, large radiation loss, and low quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A method for measuring the complex permittivity of a material based on a substrate-integrated waveguide circular resonator, comprising the following steps:

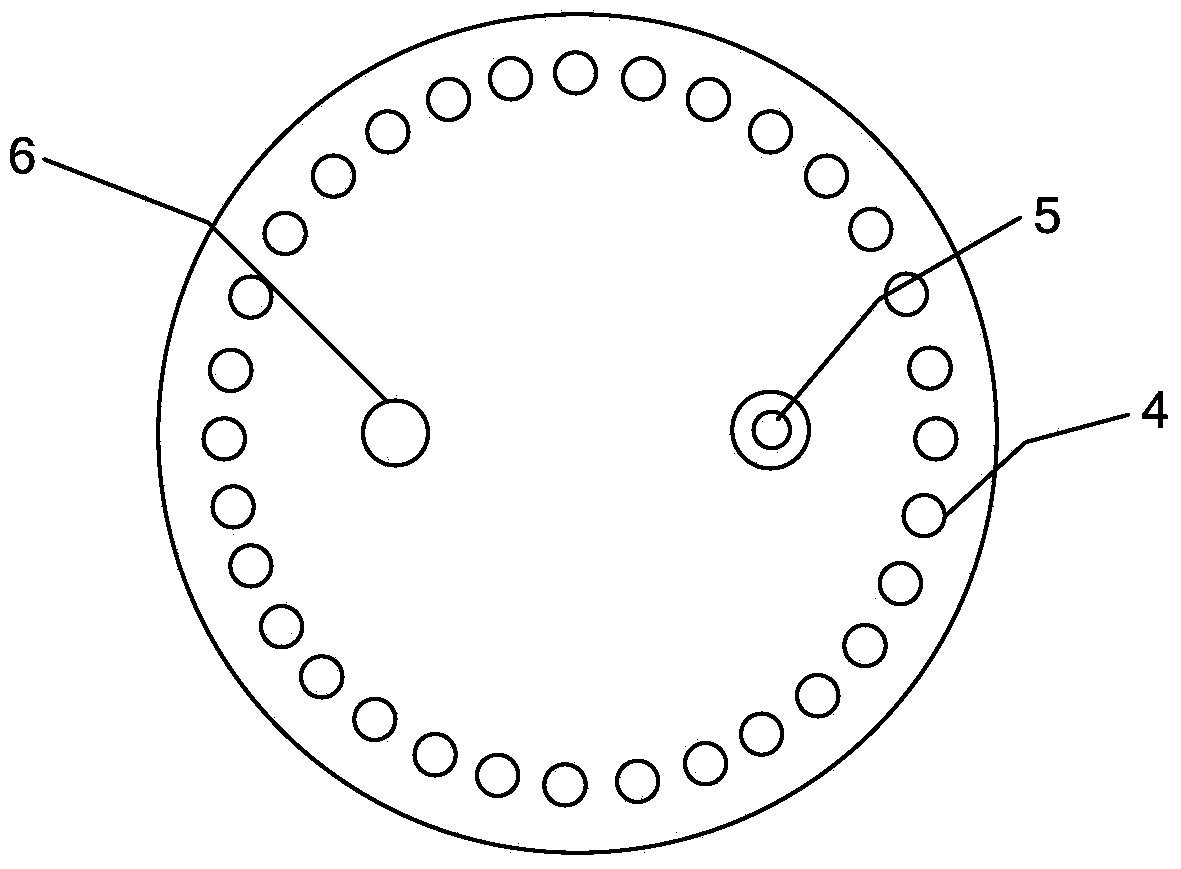

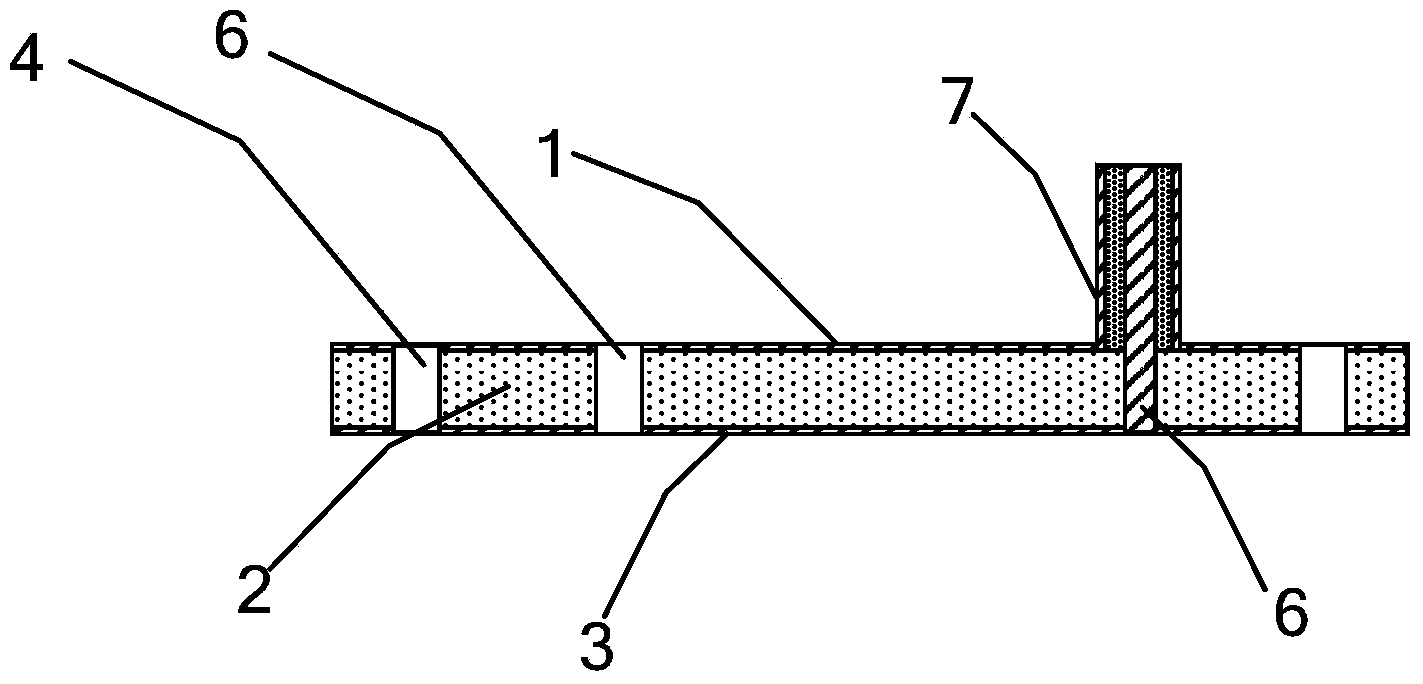

[0044] Step 1: Process substrate-integrated waveguide circular resonators with different resonant frequencies. The structure of the substrate integrated waveguide circular resonant cavity is as follows figure 1 , 2 As shown, it is processed from a dielectric plate covered with metal conductive layers on both sides, including an upper metal conductive layer 1, a dielectric layer 2, and a lower metal conductive layer 3. The dielectric layer 2 is located between the upper metal conductive layer 1 and the lower metal conductive layer. Between the conductive metal layers 3 , several metallized through holes 4 uniformly distributed in a circular shape connect the upper conductive metal layer 1 and the lower conductive metal layer 3 together. The working mode of the substrate-integrated waveguide circular resonator adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com