An optical system structure

An optical system and optical technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of lack of reach, thick thickness and large size of the optical imaging system, and achieve the effect of strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

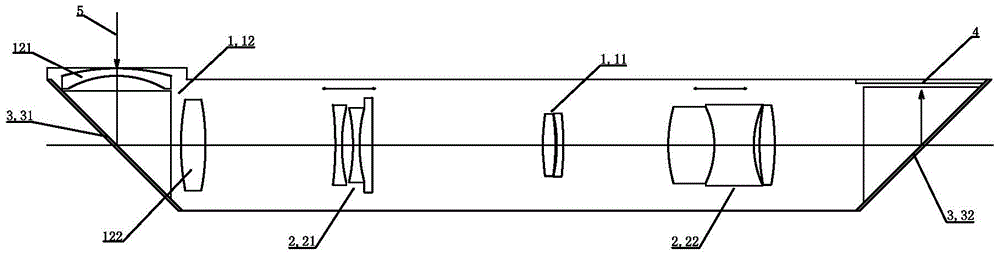

[0034] After the incident light 5 passes through the first lens 121 of the second fixed lens group 12, it is reflected by the reflective optical element 31 on the object side, and the light angle turns to 45 degrees. After passing through the second lens 122 of the second fixed lens group 12, it passes through the variable focus After passing through the first fixed lens group 11 and the focusable second movable lens group 22, the light is turned 45 degrees upward by the reflection of the reflective optical element 32 on the image side, forming an image parallel to the incident light on the optical sensing imaging surface 4 .

[0035] In this optical system structure, the zooming of the optical system is realized through the forward and backward movement on the optical axis of the first movable lens group 21 that can focus and the second movable lens group 22 that can focus. When the first moving lens group 21 moves toward the object side, the focal length becomes smaller; whe...

example 2

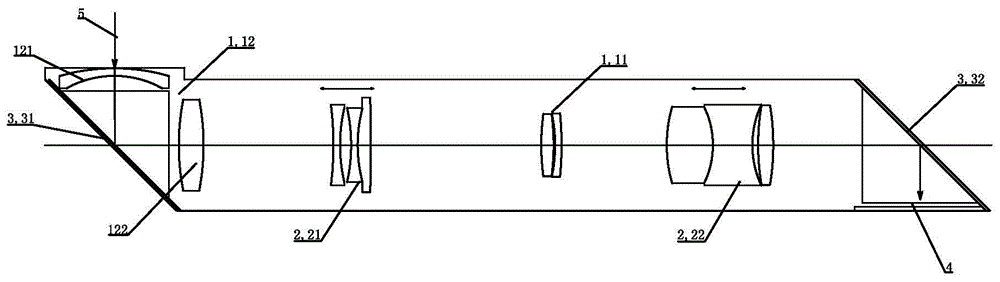

[0037] After the incident light 5 passes through the first lens 121 of the second fixed lens group 12, it is reflected by the reflective optical element 31 on the object side, and the light angle turns to 45 degrees. After passing through the second lens 122 of the second fixed lens group 12, it passes through the variable focus The first moving lens group 21, and then through the first fixed lens group 11, and the focusable second moving lens group 22, through the reflection of the image side reflective optical element 32, the light turns 45 degrees downward, parallel to the incident light The image is formed on the optical sensing imaging surface 4 .

[0038] In this optical system structure, the zooming of the optical system is realized through the forward and backward movement of the first moving lens group 21 and the second moving lens group 22 on the optical axis. When the first moving lens group 21 moves toward the object side, the focal length becomes smaller; when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com