A low-profile power module for high-frequency applications

A power module, a thin technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, high-efficiency power electronic conversion, etc., can solve problems such as chip breakdown, burning modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

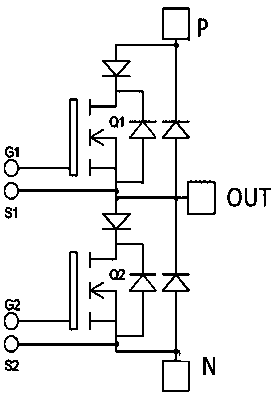

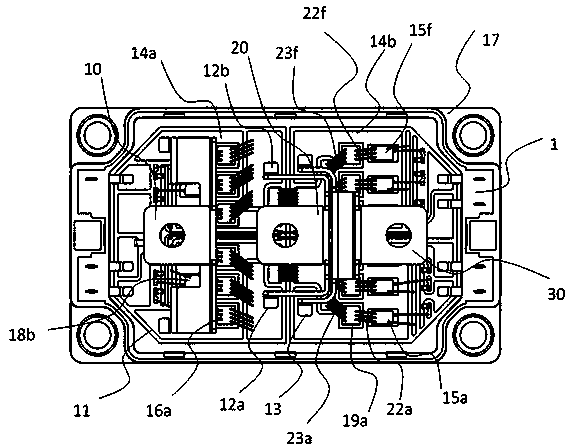

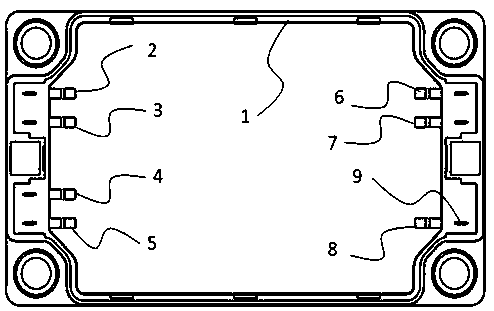

[0020] The present invention is a power module suitable for high-frequency applications. It balances the distributed inductance of the gate control loop and power loop of each chip for wide-bandgap semiconductor chips, such as silicon carbide MOSFETs, so that when the module is turned on, The current borne by each chip is basically balanced, and when the module is turned off, the voltage borne by each chip is also basically balanced. The invention is illustrated with the most common half-bridge power module. Such as figure 1 As shown, the half-bridge power module includes two silicon carbide MOSFET power units, the upper-bridge MOSFET1 and the lower-bridge MOSFET2. In actual operation, the silicon carbide MOSFETs in the upper and lower bridge arms are turned on and off alternately to control the output current. The gate loop of the upper bridge arm is G1-S1, and the gate loop of the lower bridge arm is G2-S2. The corresponding power loop of the upper bridge arm is the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com