Industrial product detection method based on machine vision

A detection method and machine vision technology, applied in the field of computer vision, can solve problems such as unreasonable threshold setting, failure of detection accuracy to meet requirements, lack of intelligence and learning judgment ability of detection technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

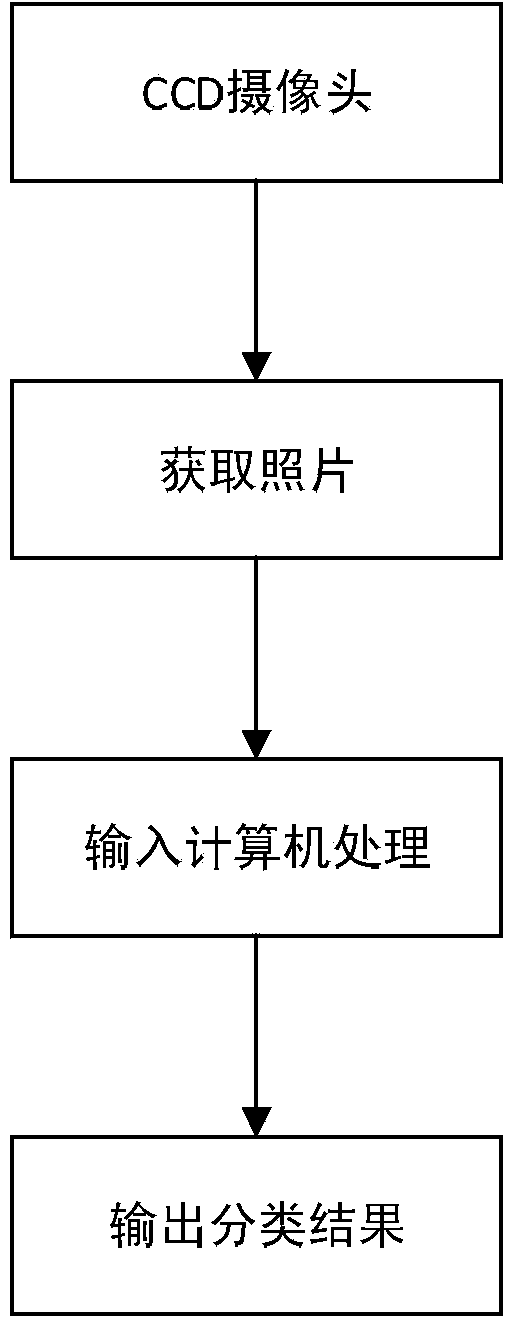

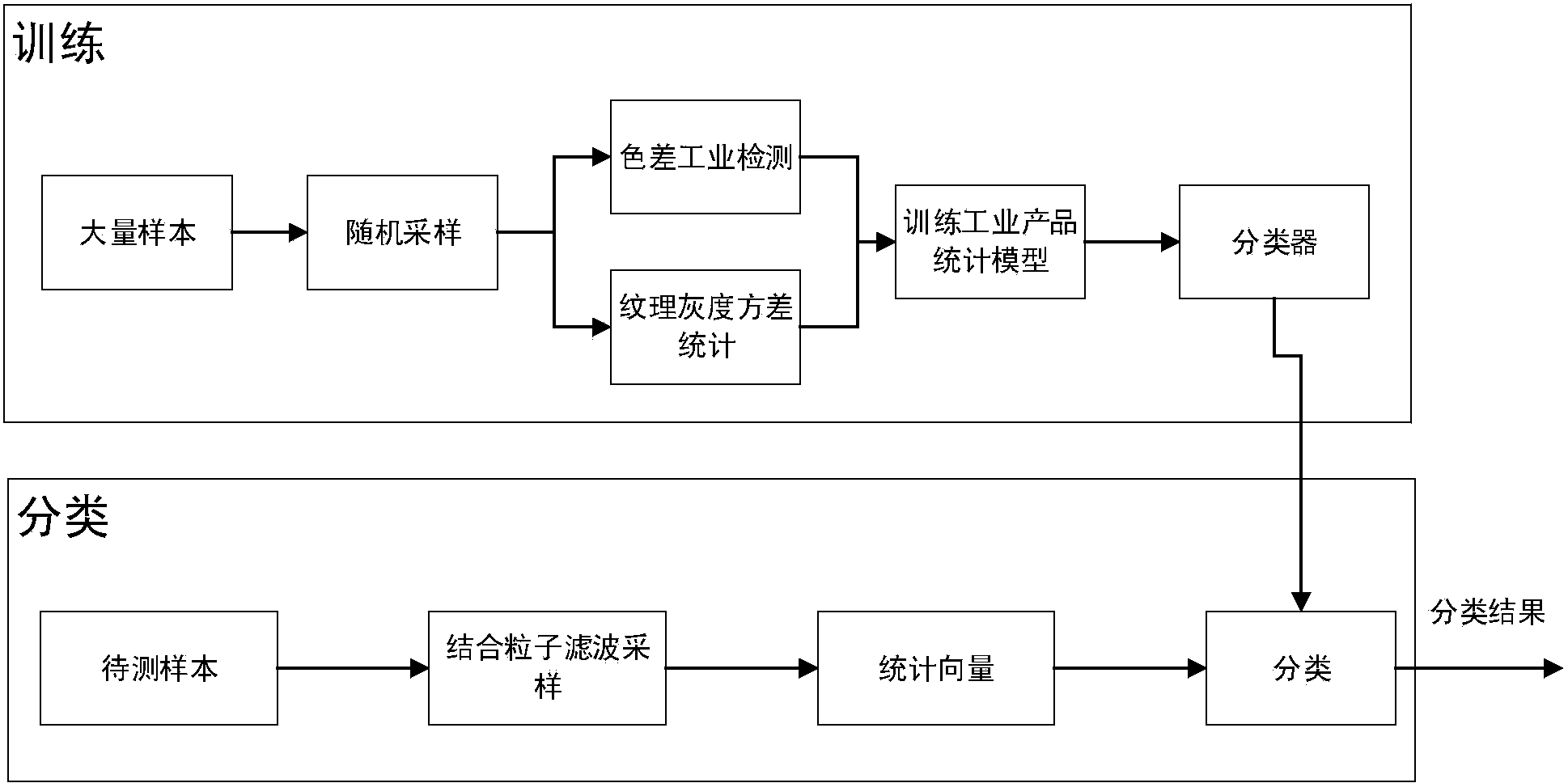

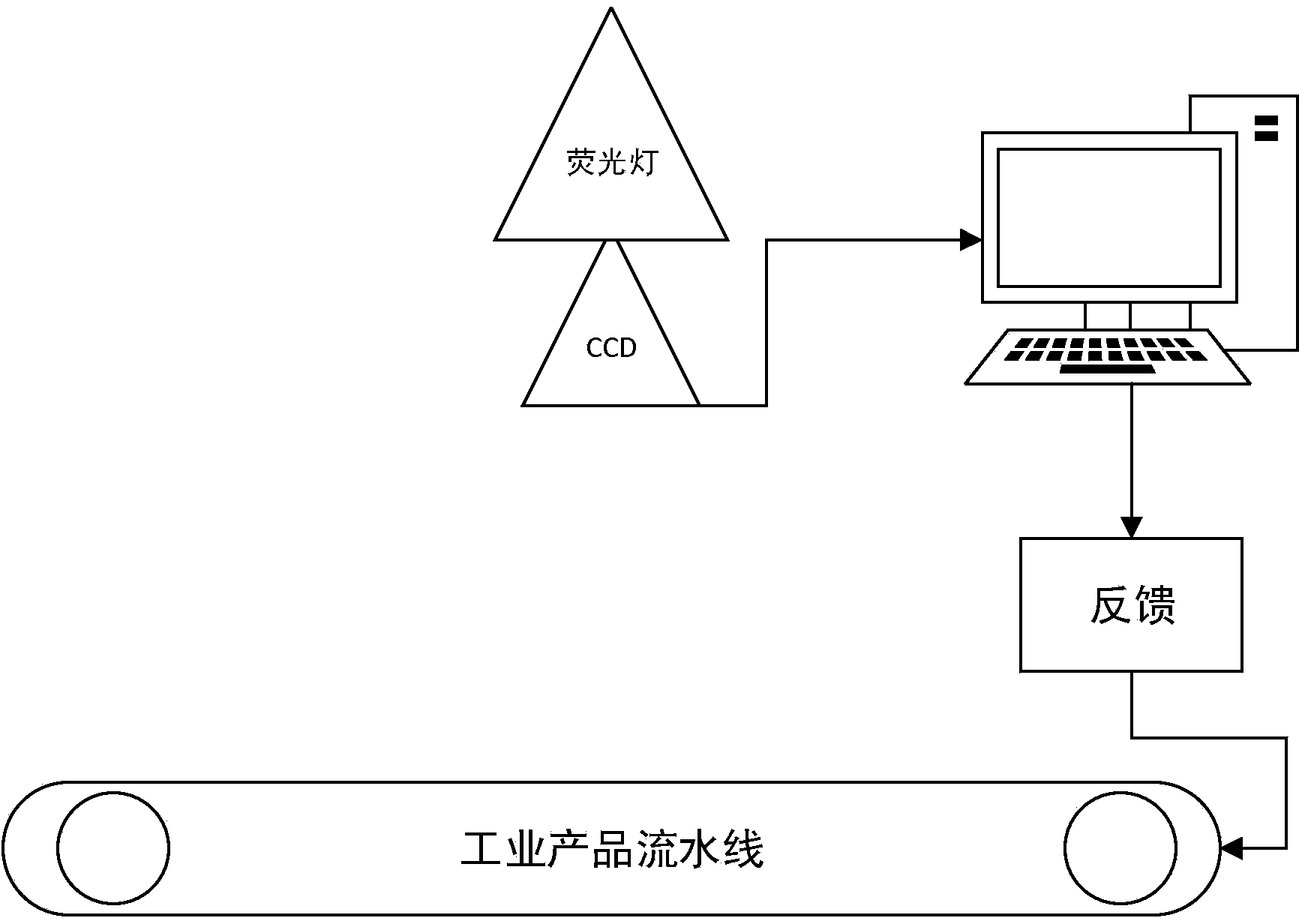

[0084] The main content of the present invention mainly focuses on the detection mechanism of machine vision, and we have adopted a simple and reliable way to realize the system of the invention. Flowchart such as figure 2 As shown, the system integration scheme is as follows ( image 3 ):

[0085] 1. Image acquisition module

[0086] The module consists of a camera and a light source, which can obtain the input of industrial product images, and the light source can ensure the clarity and accuracy of the obtained images. The camera sends the acquired image to a computer capable of image processing for information processing

[0087] 2. Image processing module

[0088] This module is the key point of the whole invention, and the technical promotion of the machine has greatly improved the reliability of the present invention, such as figure 1 As shown, this module can be divided into two key technologies of template training and sample detection. For template training, we ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com