Linear moving device

A direct-acting device and sliding plate technology, which is applied to transmission devices, electromechanical devices, and electric components, etc., can solve the problems of large motor load, large sliding resistance, and complex structure of the driving device, so as to prevent large-scale and dust intrusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

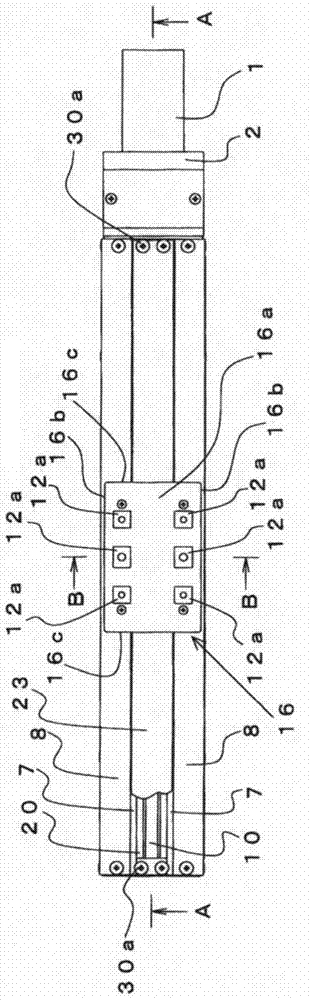

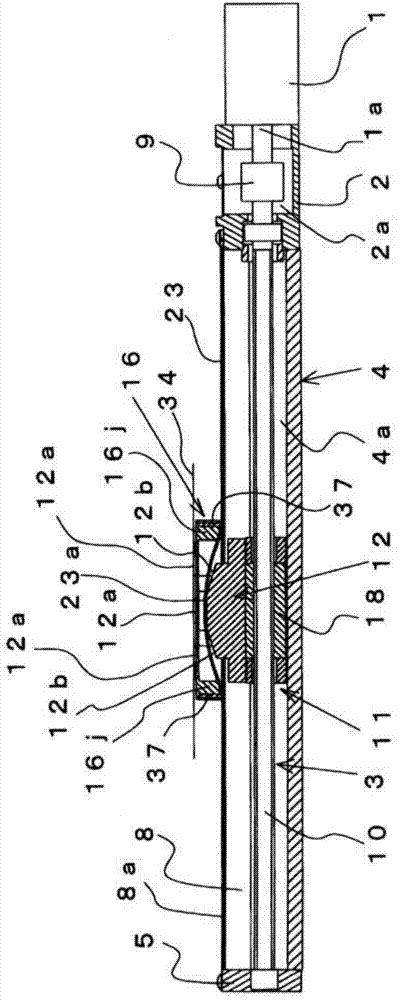

[0096] Figure 1 to Figure 13 A direct motion (direct motion) device according to the first embodiment of the present invention is shown.

[0097] In the figure, 1 is a motor, 2 is a bracket which connects the ball screw 3 accommodated in the case 4, and the motor 1.

[0098] bracket 2 as figure 1 , figure 2 As shown, one end is connected to the motor 1 via a screw. In addition, the bracket 2 is provided with a hollow portion 2 a along the axial direction of the housing 4 , and a coupling portion 9 such as a coupling is provided in the hollow portion 2 a. The motor shaft 1 a is connected to the screw shaft 10 of the ball screw 3 at the connecting portion 9 .

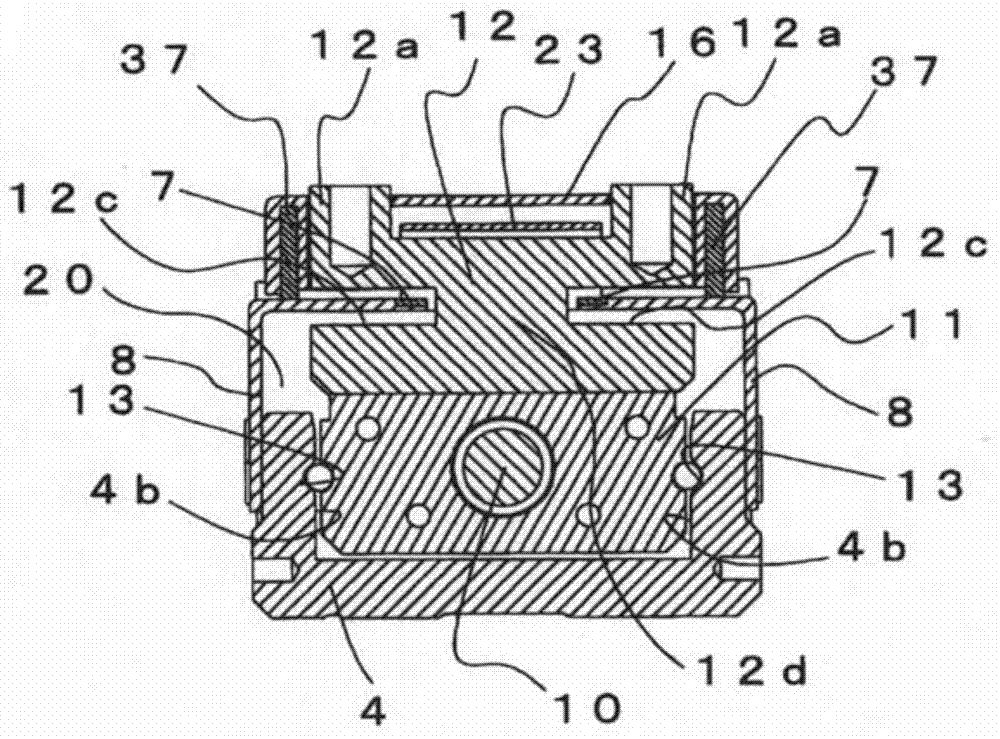

[0099] Housing 4 as figure 2 , image 3 As shown, an opening 20 is formed at the top in the axial direction along the moving direction of the slider 11 , that is, in the axial direction, and both ends in the axial direction are open. The recess 4a formed by the opening 20 is formed with a guide groove 13 for fre...

no. 2 approach )

[0165] Figure 15 to Figure 18 A linear motion device according to a second embodiment of the present invention is shown.

[0166] The linear motion device may require the length of the table 12 to be increased in order to increase the bearing capacity of the table 12 .

[0167] However, in the linear motion device related to the first embodiment, if it is desired to increase the bearing capacity of the workbench 12, the workbench 12 such as image 3 As shown, since the recesses 12c into which the side covers 8 enter are formed on both sides in the longitudinal direction, the table 12 is formed with narrowed portions 12d, and the strength of the table 12 may decrease.

[0168] Therefore, in this embodiment, the bearing capacity of the workbench 12 can be increased by lengthening the length of the workbench 12 and increasing the cross-sectional area of the narrowed portion 12d.

[0169] And, if the bending portion 23a of the belt-shaped sealing ring 23 passing through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com