Maybush pitter

A hawthorn and de-nucleating technology, applied in fruit de-nucleating device, food science, application and other directions, can solve the problems of high labor intensity, low production efficiency, backward processing methods, etc., to ensure safety and hygiene, improve work efficiency, and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

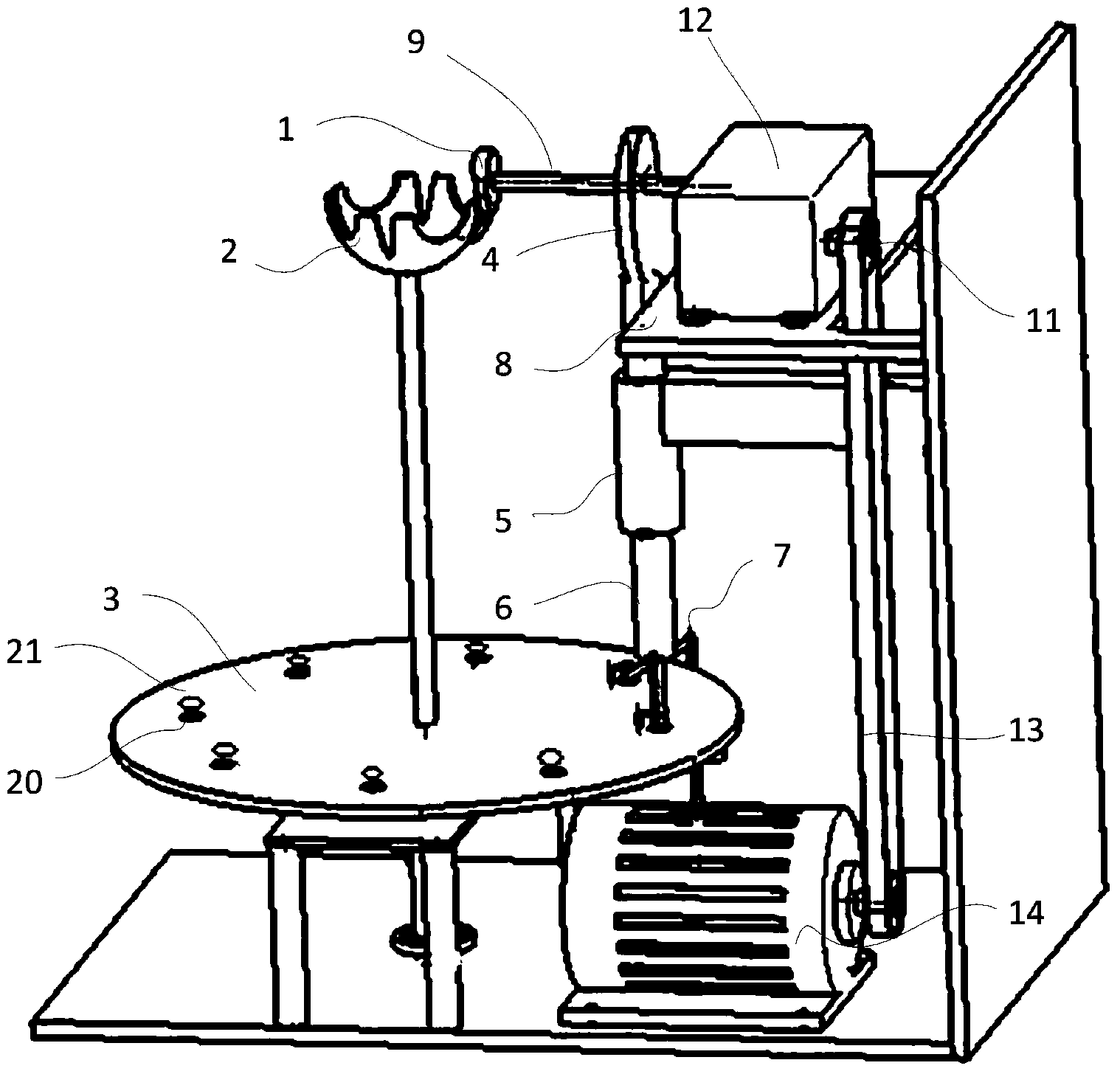

[0019] Below in conjunction with embodiment and attached figure 1 The present invention is further described.

[0020] Please refer to figure 1 , figure 1 It is a structural representation of the hawthorn corer of the present invention, figure 1 Among them, the hawthorn coring device includes a table rotary mechanism, a nuclear mechanism and a driving mechanism.

[0021] The denucleating mechanism includes a cam 4, a tool holder 5 and a cutter 6 connected in sequence, the cutter head of the cutter 6 is a single cutter head or a double cutter head, the cam 4 is connected to the main shaft 9, and the worktable rotary mechanism has The indexing workbench 3 of hawthorn is placed at the preset position, and the driving mechanism has a main shaft 9 connecting the turning mechanism of the worktable and the denucleating mechanism at the same time, and the rotation of the main shaft 9 drives the indexing work The rotation of table 3 and the operation of the denucleating mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com