Method for processing coiling block rope race

A processing method and drum rope groove technology, applied in the field of machinery, can solve problems such as low processing efficiency, messy rope, stuck rope, etc., and achieve the effect of improving processing efficiency and chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

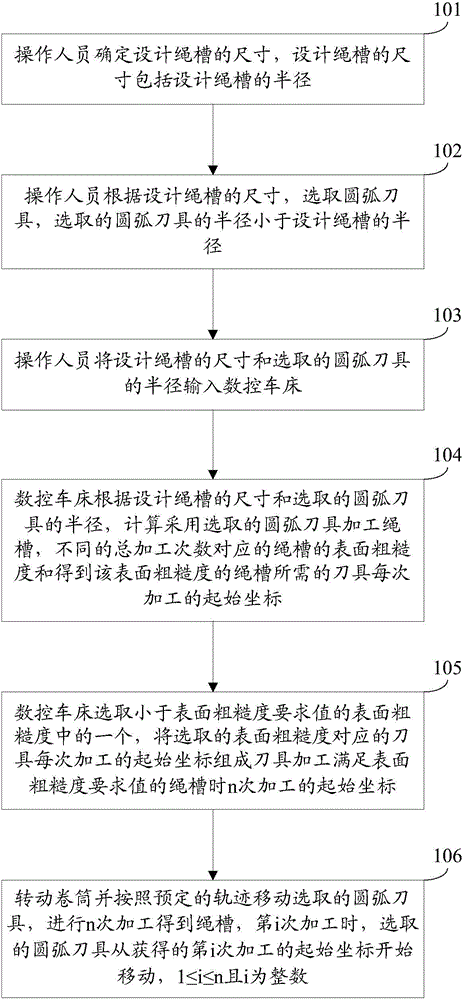

[0041] The embodiment of the present invention provides a method for processing the rope groove of the drum, which is especially suitable for processing the rope groove of the drum of the ultra-large offshore crane. The method can be realized by using a numerical control machine tool, see figure 1 , the method includes:

[0042] Step 101: The operator determines the size of the designed rope groove, and the designed size of the rope groove includes the radius of the designed rope groove.

[0043] In this embodiment, the designed rope groove is an ideal rope groove with a surface roughness of 0. The section of the ideal rope groove is a standard arc shape, and the surface roughness is the maximum distance between the non-coincident points of the rope groove section and the standard arc surface of the same radius when the center of the circle coincides. The size of the designed rope groove also includes the depth of the designed rope groove and / or the included angle of the arc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com