Patents

Literature

87 results about "Start coordinates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

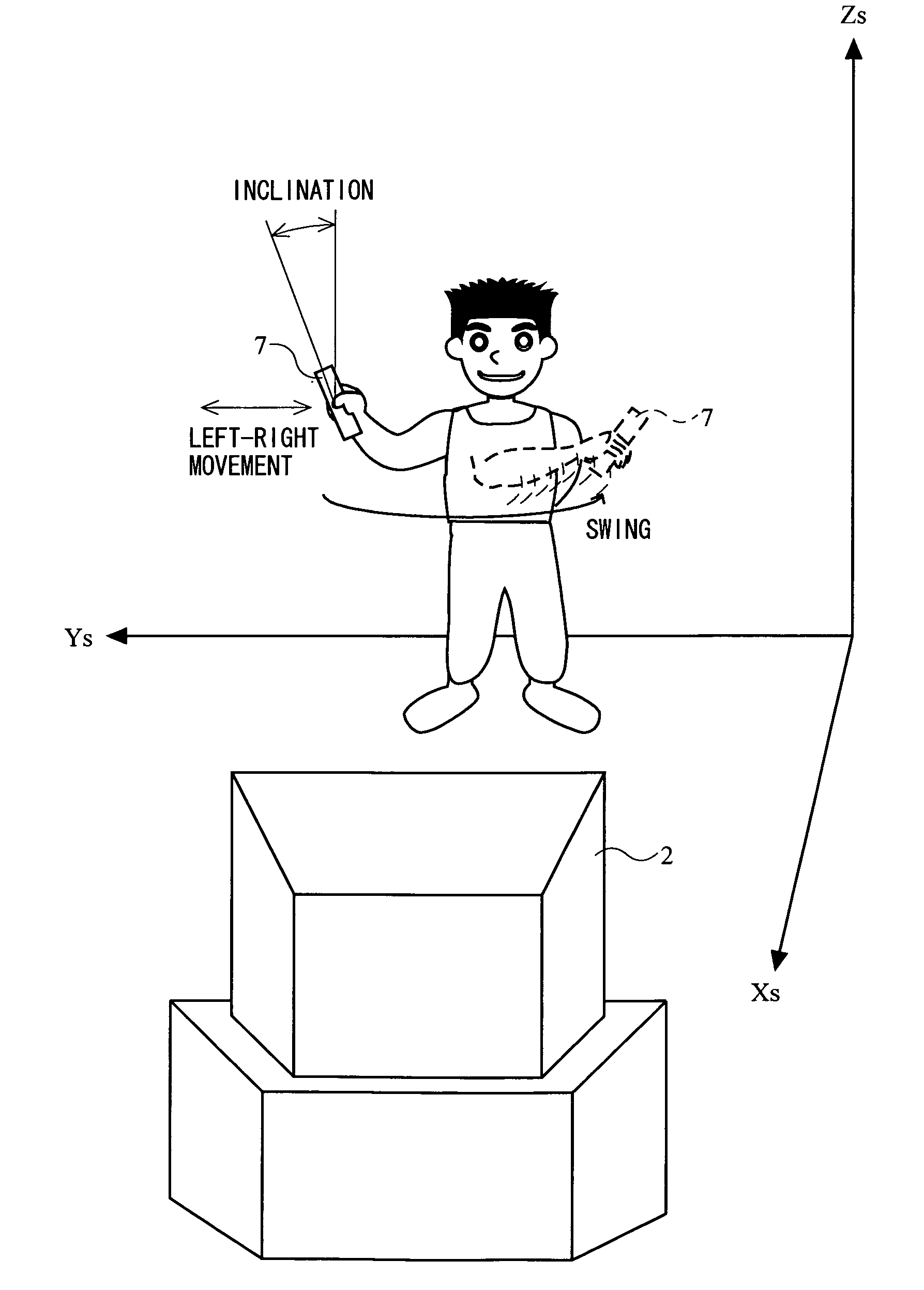

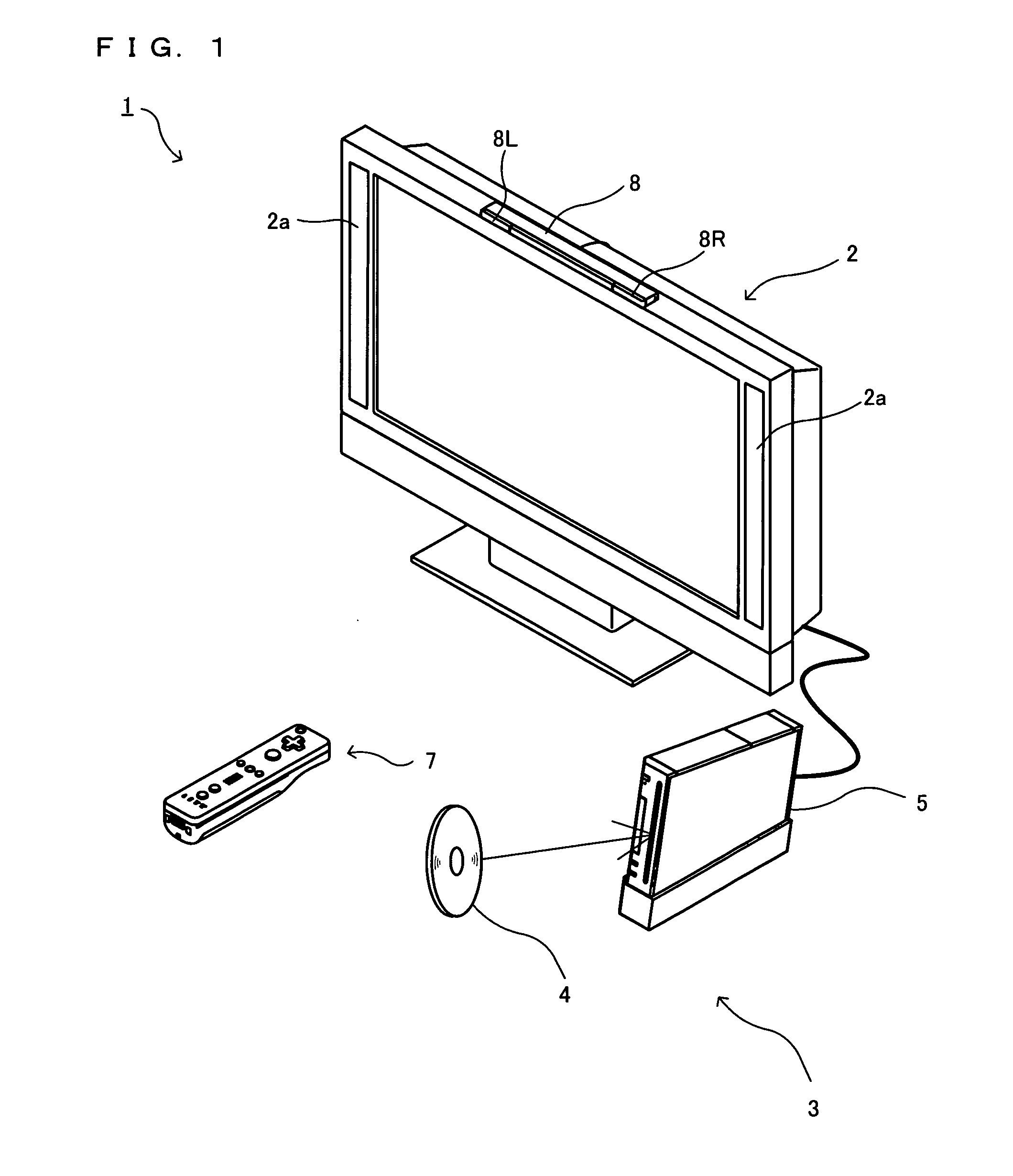

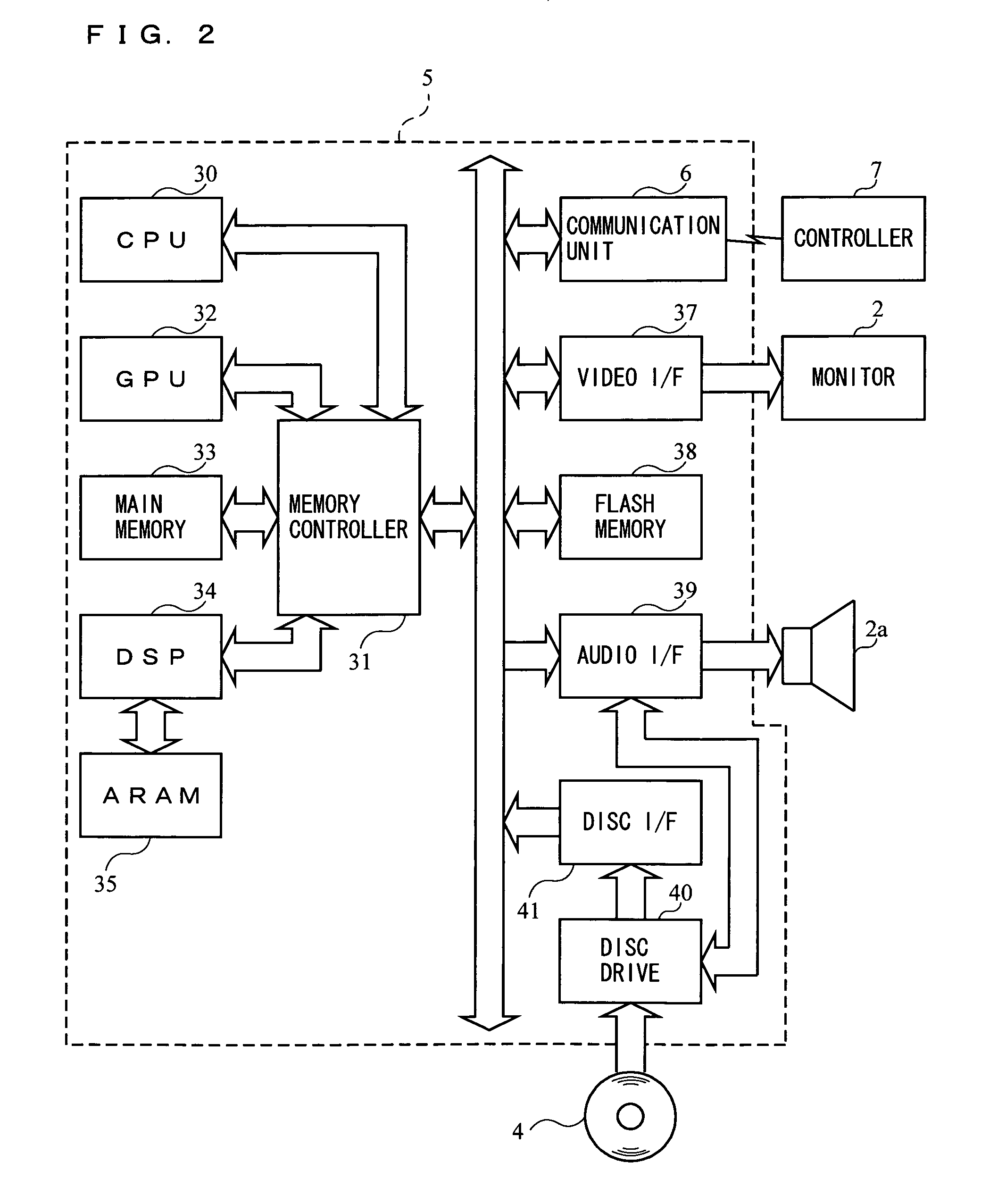

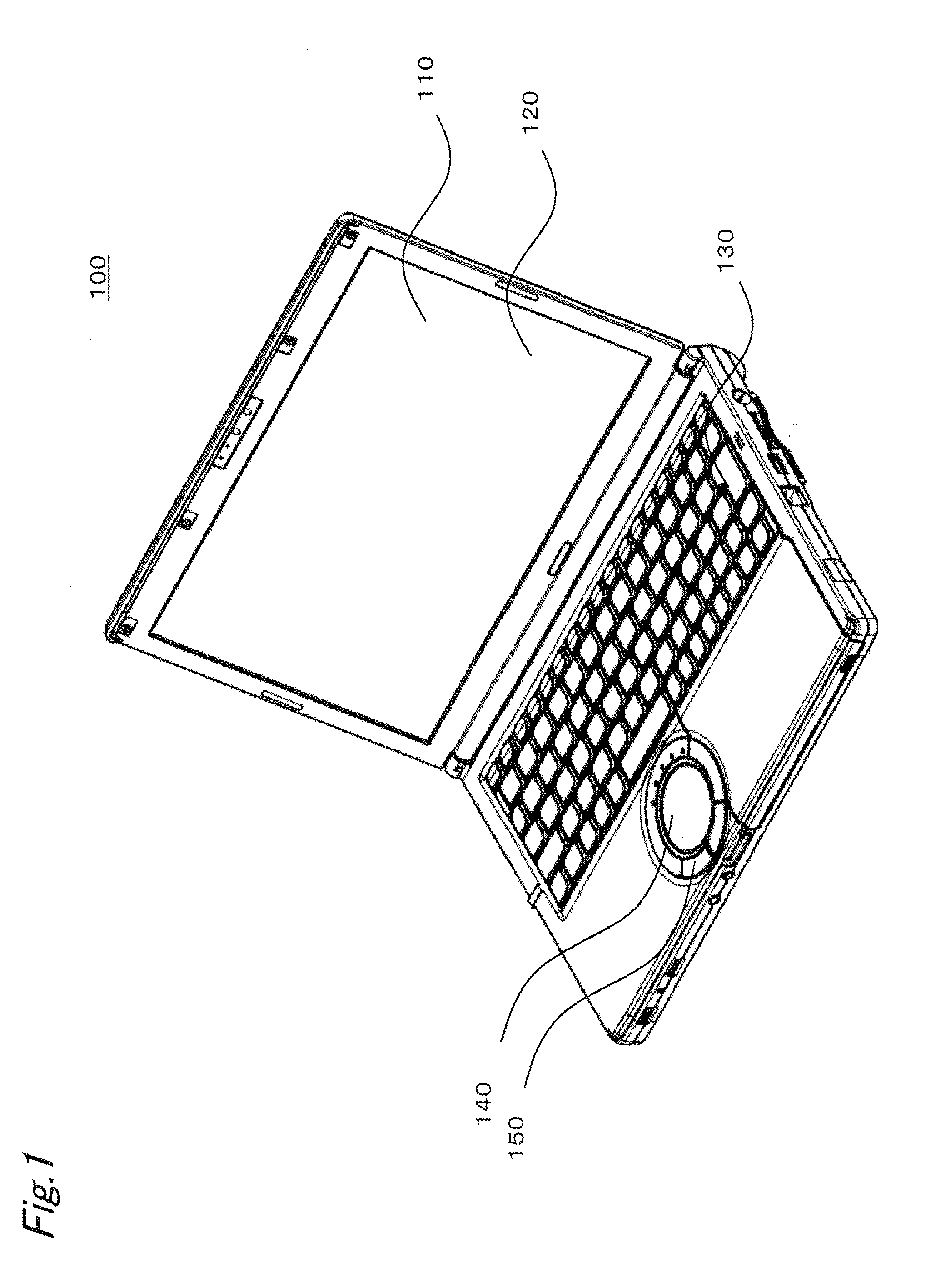

Storage medium having game program stored thereon and game apparatus

InactiveUS20080076566A1Reduce processing loadVideo gamesSpecial data processing applicationsDisplay deviceVirtual game

A moving start coordinate set associated with an object is calculated based on motion data output from a motion sensor for outputting the motion data in accordance with a motion of an input device, and a first difference coordinate set, as a difference between the moving start coordinate set and a reference trajectory, is calculated. A target coordinate set associated with the object is calculated, and a second difference coordinate set, as a difference between the target coordinate set and a reference trajectory, is calculated. A change difference coordinate set changing from the first difference coordinate set to the second difference coordinate set in accordance with time is calculated. The change difference coordinate set is added to the reference trajectory to calculate a correction coordinate set. The object is located at a position corresponding to the correction coordinate set in the virtual game space and displayed on the display device.

Owner:NINTENDO CO LTD

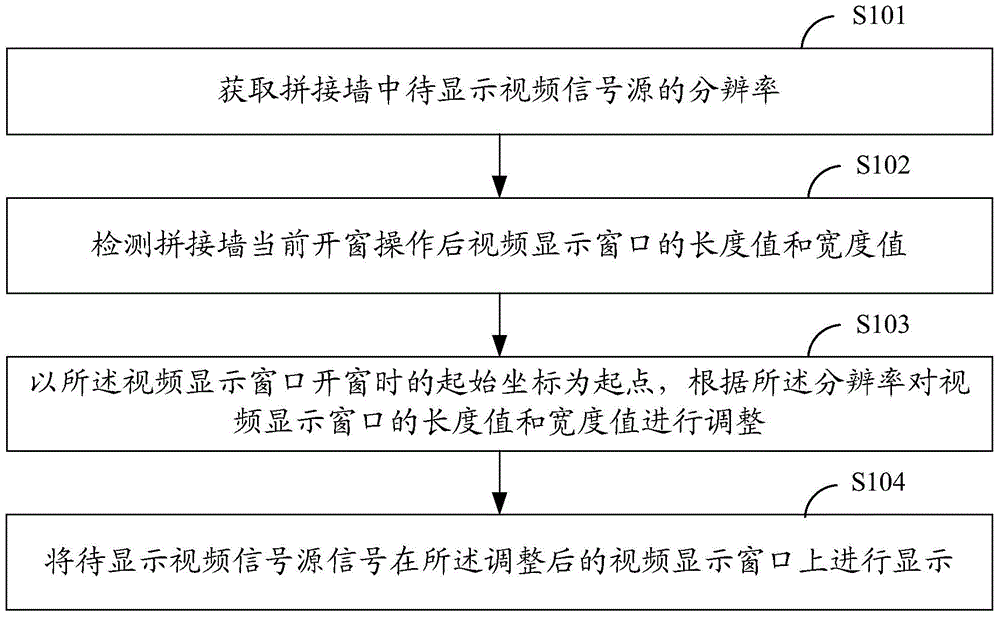

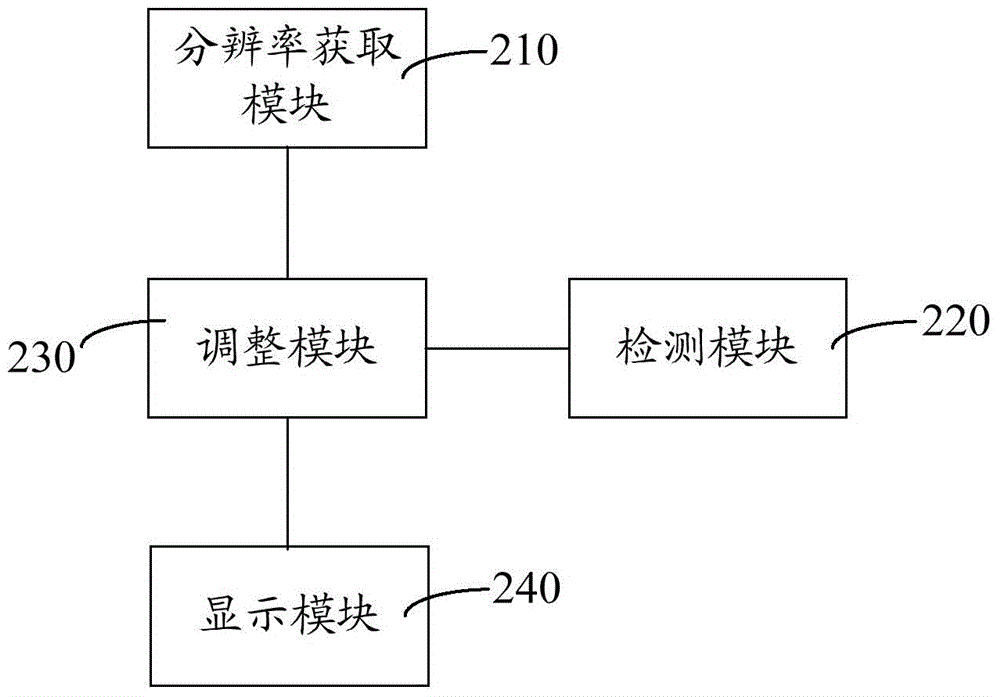

Method and system for regulating video display window of jointing wall

InactiveCN104461295AAvoid distortionInput/output processes for data processingImage resolutionSignal source

The invention discloses a method and a system for regulating a video display window of a jointing wall. The method comprises the following steps: obtaining resolution of a video signal source to be displayed in the jointing wall; detecting the length value and the width value of the video display window after the existing windowing operation of the jointing wall, wherein the video display window is a window for displaying the video signal source to be displayed; regulating the length value and the width value of the video display window according to the resolution by taking the starting coordinates of the video display window during windowing as a starting point; displaying the video signal source to be displayed on the regulated video display window. The scheme adopted by the invention can be used for avoiding display frame distortion of the window due to a length-width ratio.

Owner:GUANGDONG VTRON TECH CO LTD

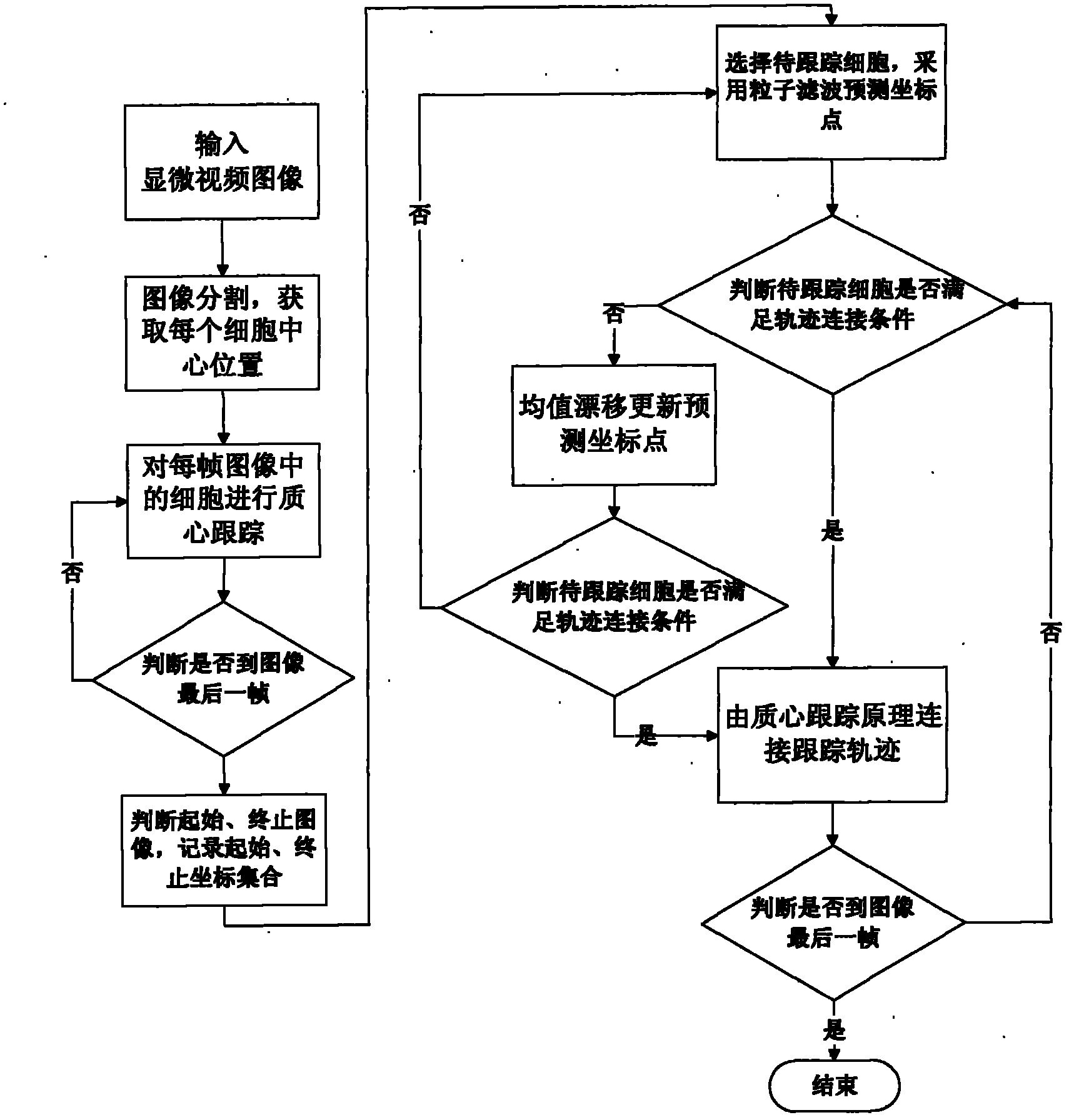

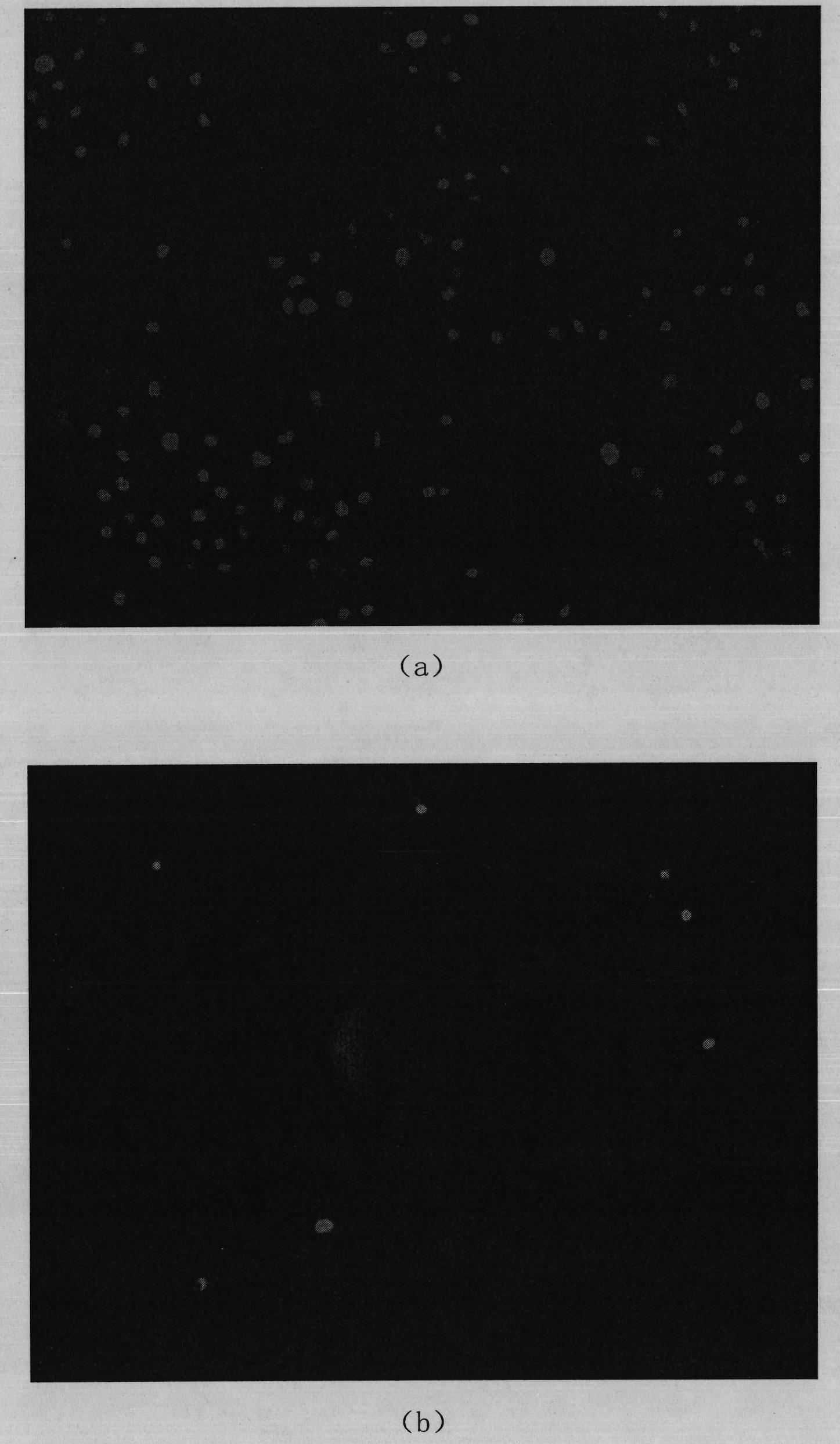

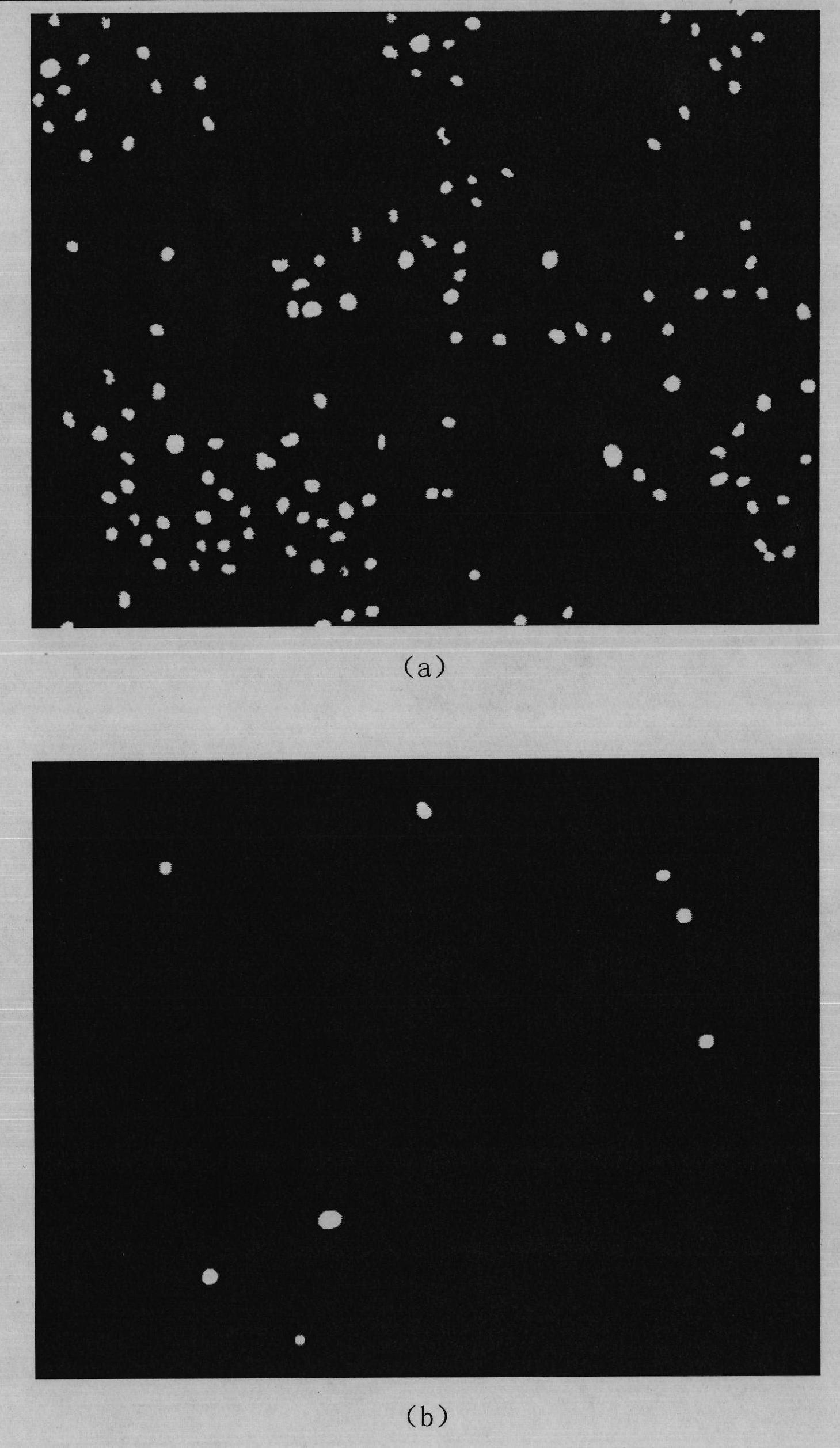

Centroid tracking framework based particle filter and mean shift cell tracking method

The invention discloses a centroid tracking framework based particle filter and mean shift cell tracking method, which mainly solves the problem of low accuracy rate of the traditional cell tracking method. The cell tracking method comprises the following steps of: performing binary segmentation to a video image, and extracting the central position of each cell; tracking the centroid of the cell, and recording the tracking trace of the cell; respectively recording the starting coordinates and the terminating coordinates of the trace into a starting coordinate set and a terminating coordinate set, and selecting a cell to be tracked; further predicting the trace of the cell to be tracked by using particle filter to obtain a predicted coordinate point in the next frame of image; selecting the subsequent tracking trace of the cell to be tracked by using the mean shift method in good time according to the predicted coordinate point; and circulating the steps of prediction and selection till the last frame of image, and completing the tracking of all cells. Compared with other traditional tracking methods, the cell tracking method has improvement in the aspects of tracking effect and accuracy rate and can be used for analyzing motor cells in a medical microscope video image.

Owner:XIDIAN UNIV

Unlocking method and terminal

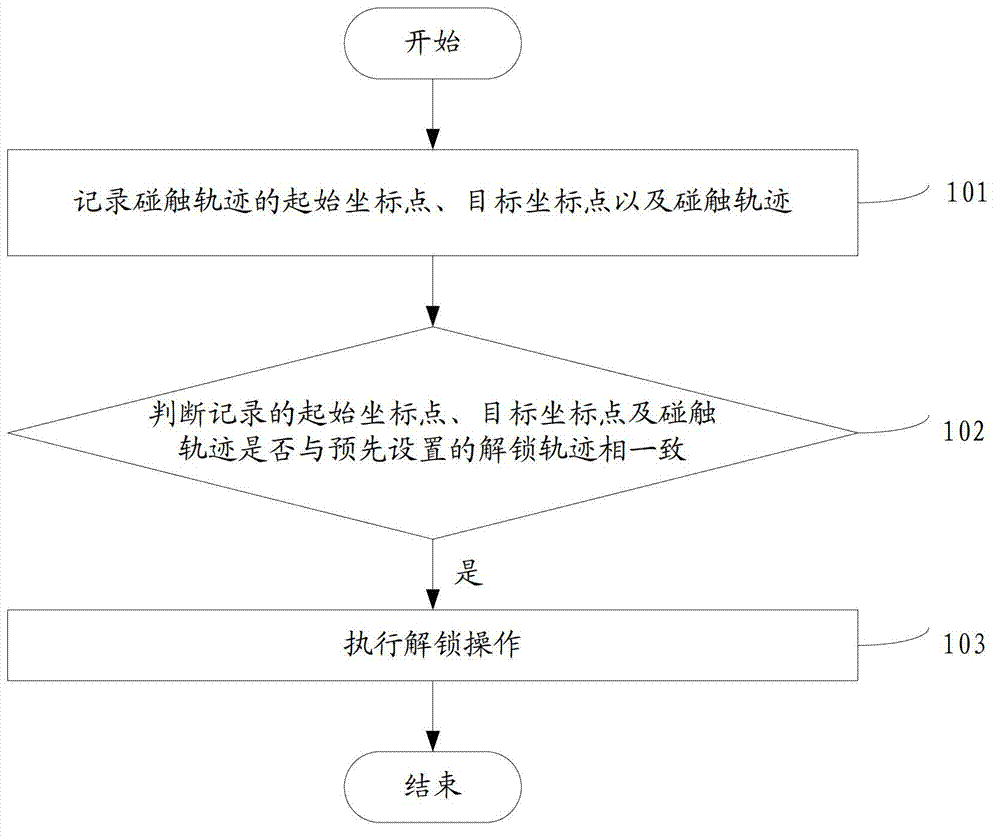

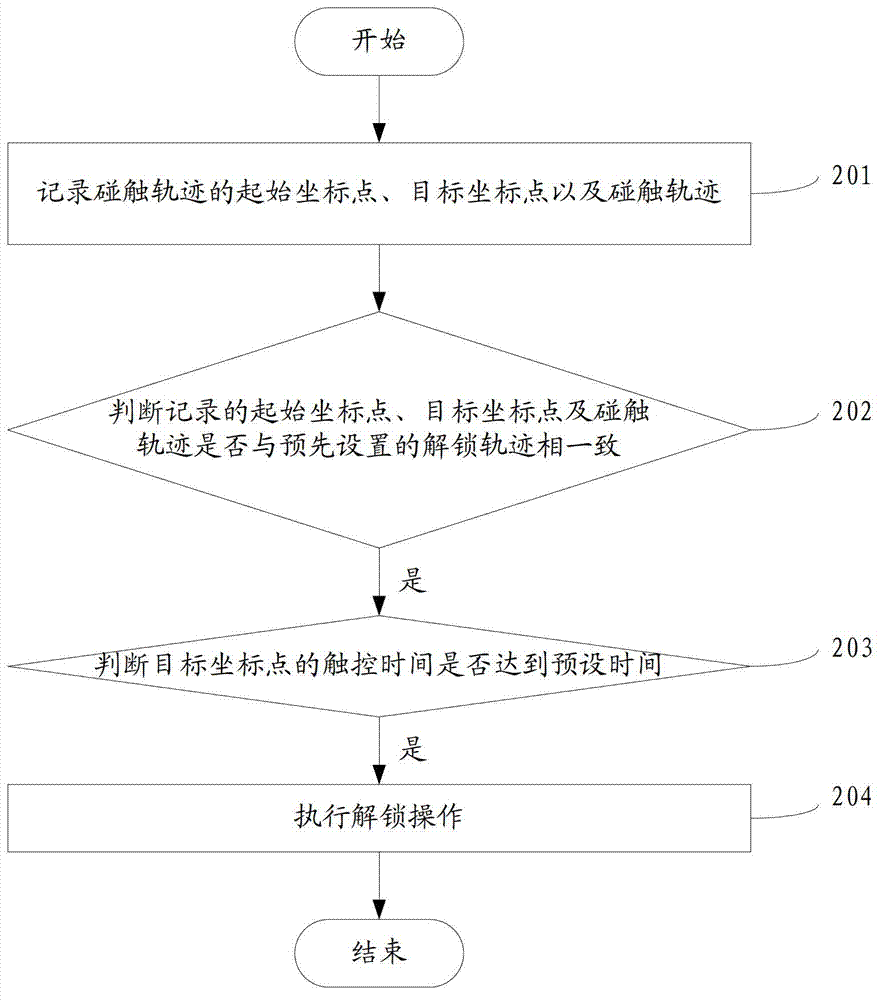

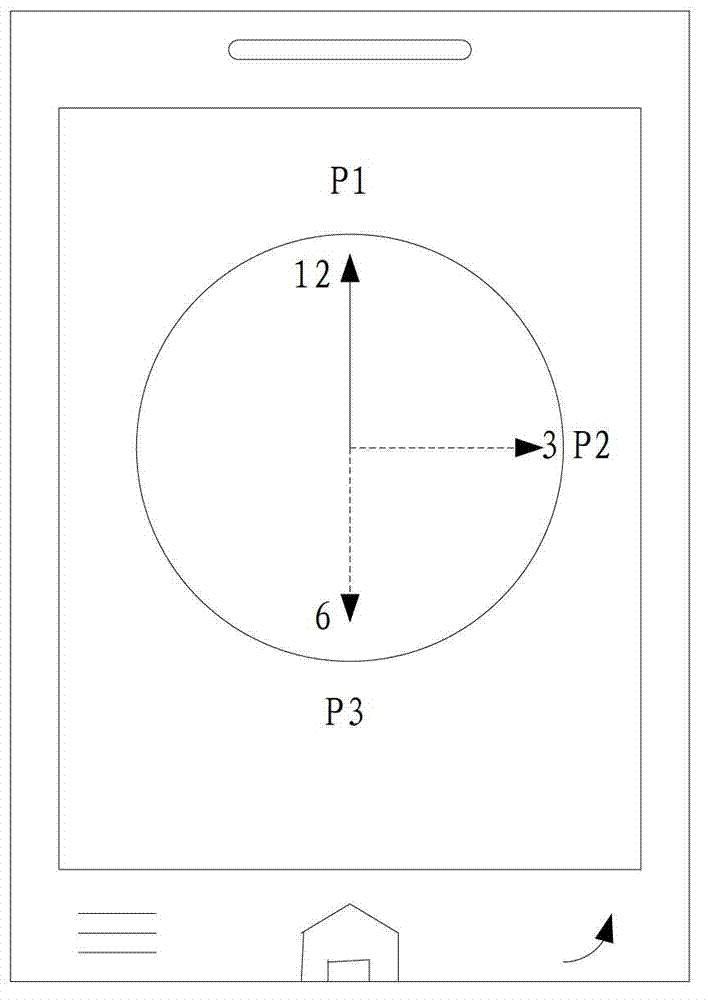

ActiveCN103034448AIncrease diversityAdd funInput/output processes for data processingInformation processingConfidentiality

The invention discloses an unlocking method and a terminal, belonging to the technical field of information processing. The unlocking method comprises the following steps of: recording a start coordinate point and an object coordinate point of a touch track and the touch track; judging whether the recorded start coordinate point, object coordinate point and touch track are consistent to a preset unlocking track; and if the recorded start coordinate point, object coordinate point and touch track are consistent to the preset unlocking track, executing unlocking operation. The invention has the advantages that by recording the touch track and executing the unlocking operation after judging that the touch track is consistent to the preset unlocking track, not only are the diversity and the interestingness of unlocking added, but also the confidentiality is enhanced simultaneously when the prevention of misoperation is realized.

Owner:XIAOMI INC

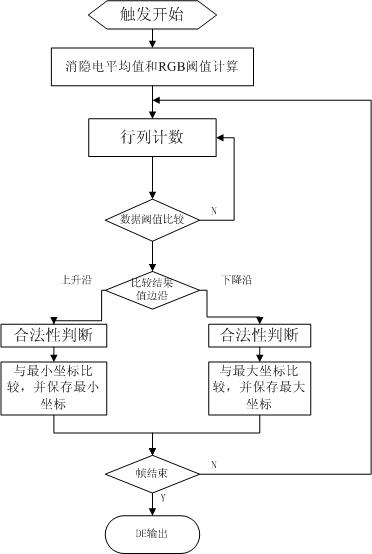

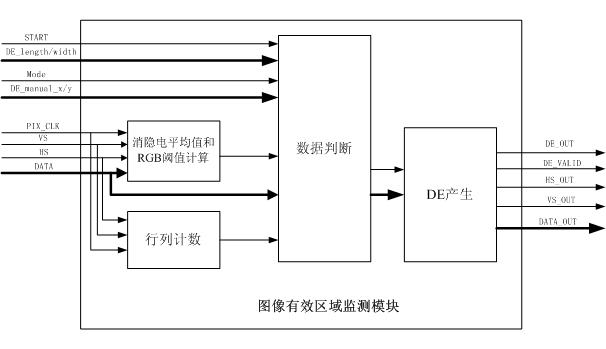

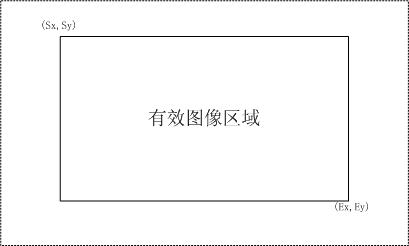

Effective image area detection method and system

The invention discloses an effective image area detection method and an effective image area detection system. By the method and the system, the aims of automatically identifying the effective area of an analogue signal and regulating an optimal display position are fulfilled, and the problem of blackedging in the display of the analogue image signal is effectively solved. The method comprises the following steps of: detecting whether image data corresponding to each pixel clock belongs to an effective image or not, and recording coordinate values of the image data; taking counted minimum row and column coordinates as starting coordinates of the effective image area, and taking counted maximum row and column coordinates as the ending coordinates of the effective image area; and finally making a range judgment on a detection result, and outputting an effective signal if a range is legal.

Owner:GUANGDONG VTRON TECH CO LTD

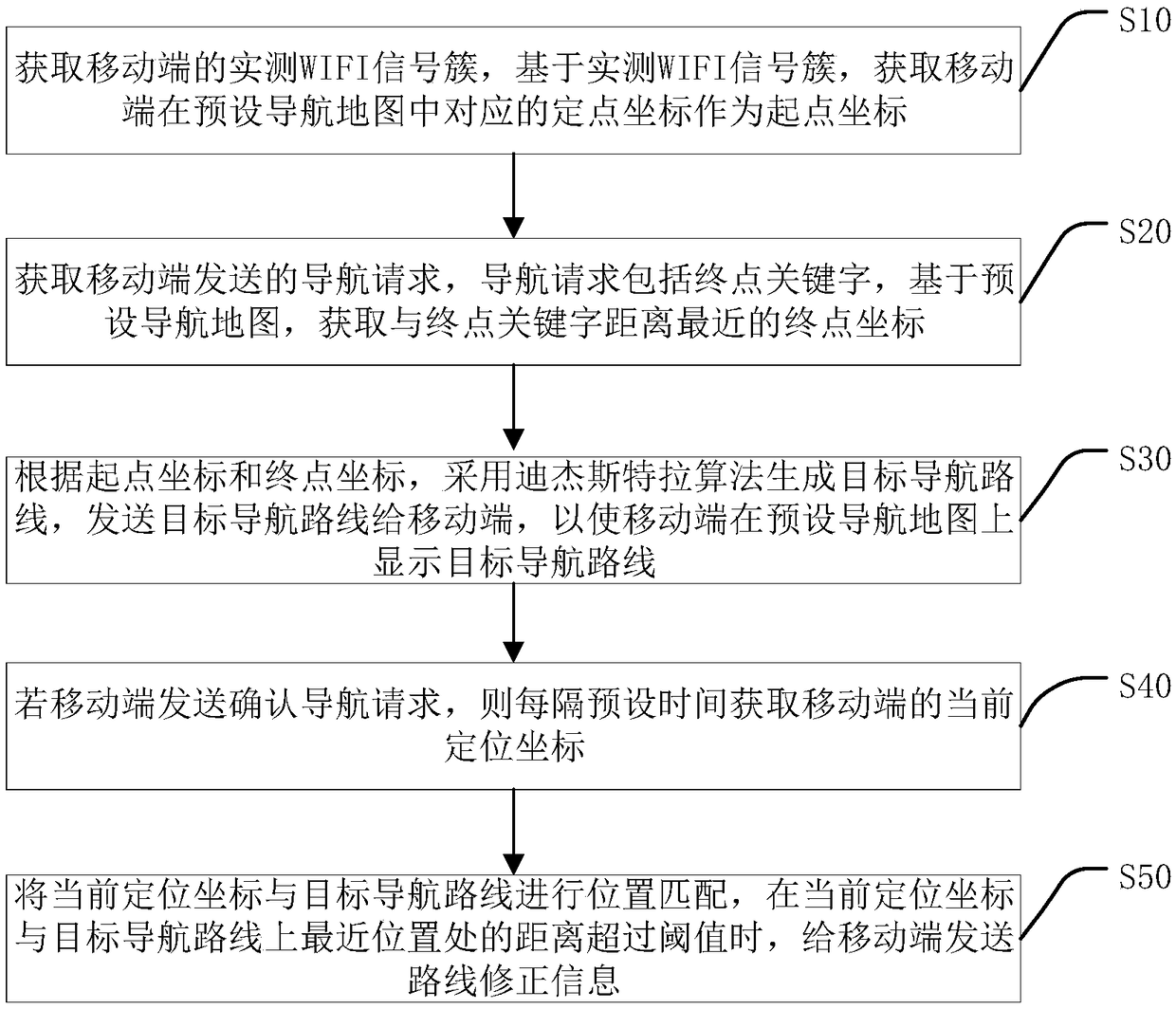

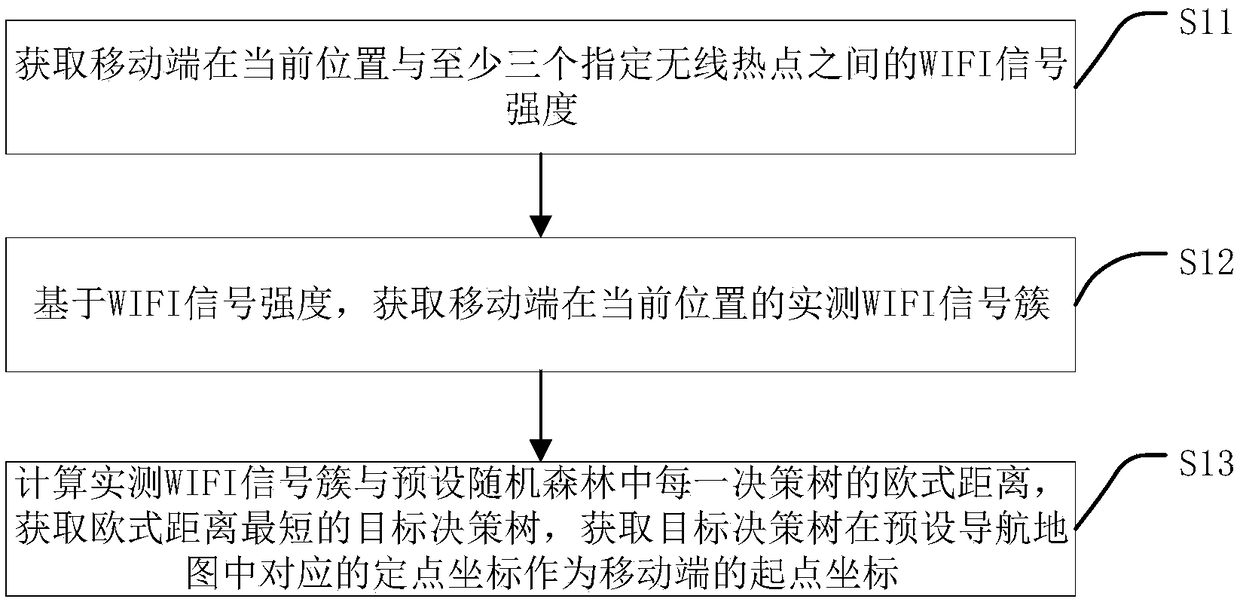

Indoor navigation method, device, computer equipment and storage medium

PendingCN109239660AFind exactlyUnaffected by strengthNavigational calculation instrumentsParticular environment based servicesMobile endMarine navigation

The invention discloses an indoor navigation method and device, and a computer equipment and storage medium. The indoor navigation method comprises the following steps of: obtaining a corresponding pointing coordinate of a mobile terminal in a preset navigation map as a start coordinate; obtaining an end coordinate closest to an end point keyword distance; adopting the Dijkstra algorithm to generate a target navigation route according to the start coordinate and the end coordinate, and sending a target navigation route to the mobile terminal; acquiring the current positioning coordinates of the mobile terminal every preset time if the mobile terminal sends a confirmation navigation request; and matching the current positioning coordinate with the target navigation route, and sending the route correction information to the mobile terminal when the distance between the current positioning coordinate and the nearest position on the target navigation route exceeds the threshold. The methodcan track the moving route of the mobile terminal and give the route correction information in time, thereby ensuring that the mobile terminal can quickly and accurately find an indoor destination.

Owner:PING AN TECH (SHENZHEN) CO LTD

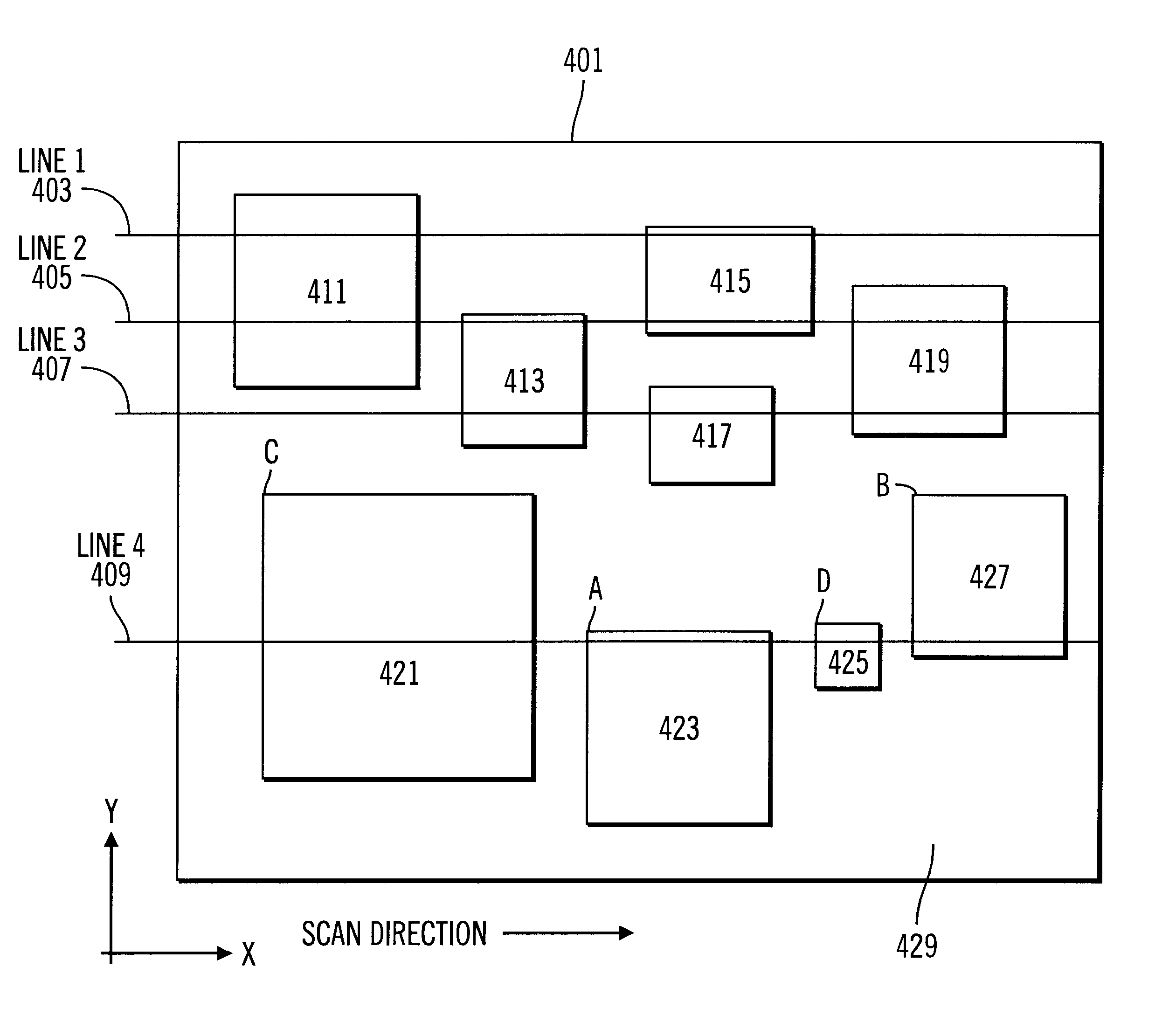

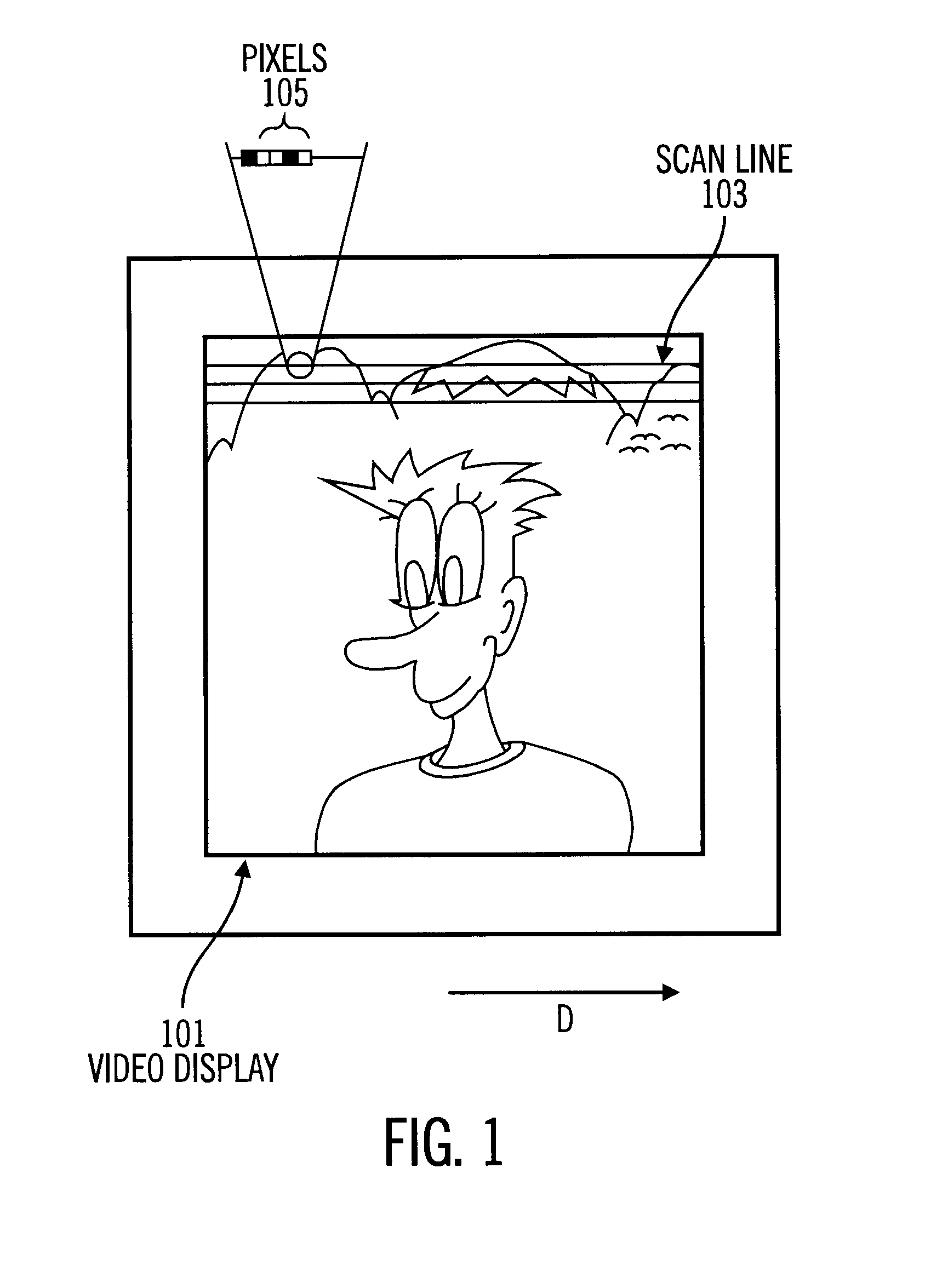

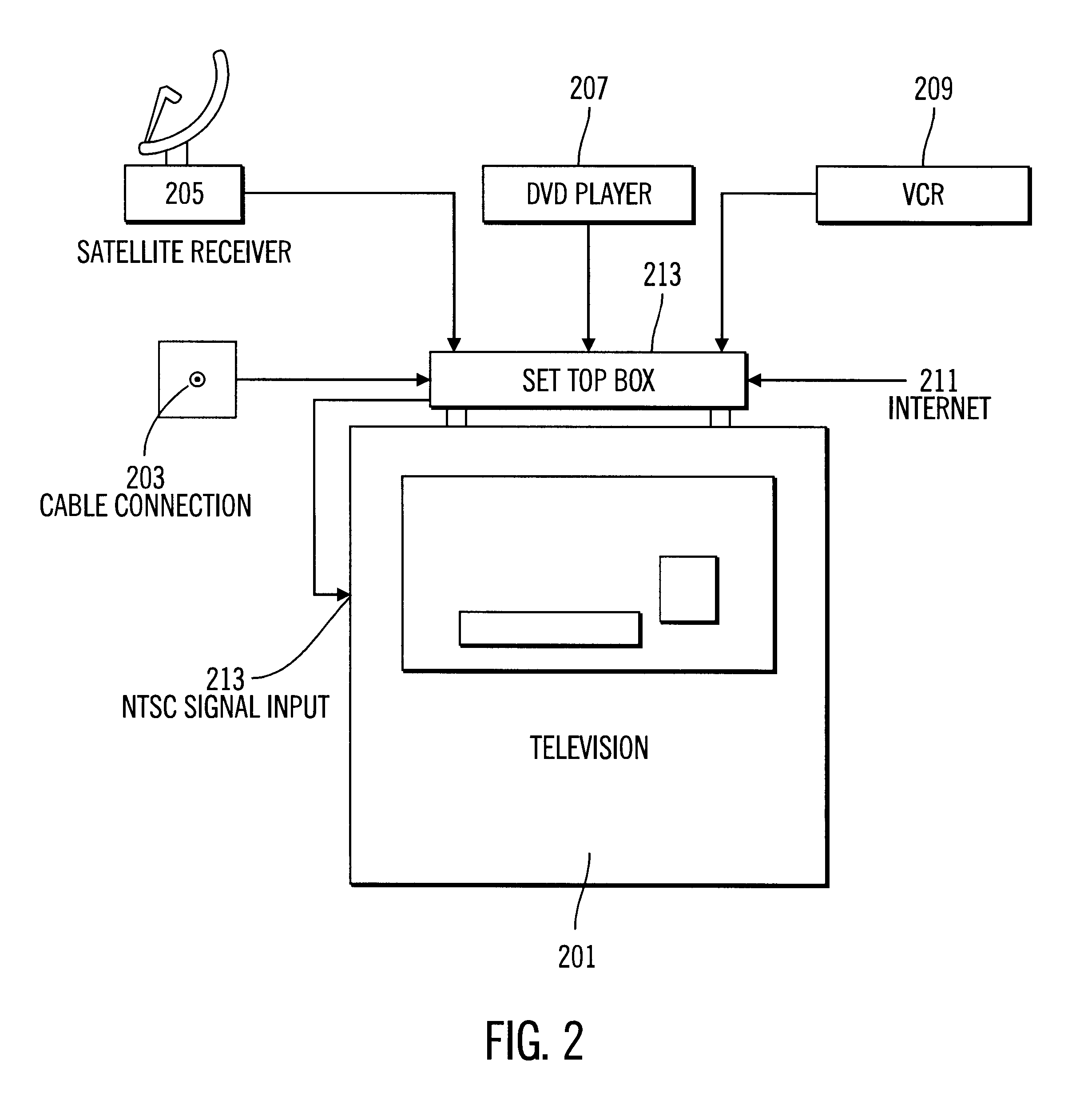

Adding method for ordered sorting of a group of windows on a display

InactiveUS6392672B1Alter its performanceSpeed up determinationInput/output processes for data processingDisplay deviceFrequent use

In modern display systems, such as cable boxes, there is often a requirement to create displays with several windows containing independent content. The content may come from different programs running within the system and may also come from real time video inputs such as satellite TV signals, DVD players, cable companies, and the like. In such applications the on screen display can be created on a line by line basis. Often the display lines can be created as they are being used. To create these display lines it is necessary to sequence the data to the display in the order which it will be displayed. To sequence the data to the display in the order which it will be displayed the windows must be sorted by their position on the screen. To sort the windows by their position on the screen such methods as doing a bubble sort of the window's starting coordinates is often used. The present invention presents a method and apparatus that compares the position of the window to the others on the same line and then numerically adds the results. The numerical value of the results then directly gives the order in which the window will be displayed.

Owner:CONEXANT SYST INC

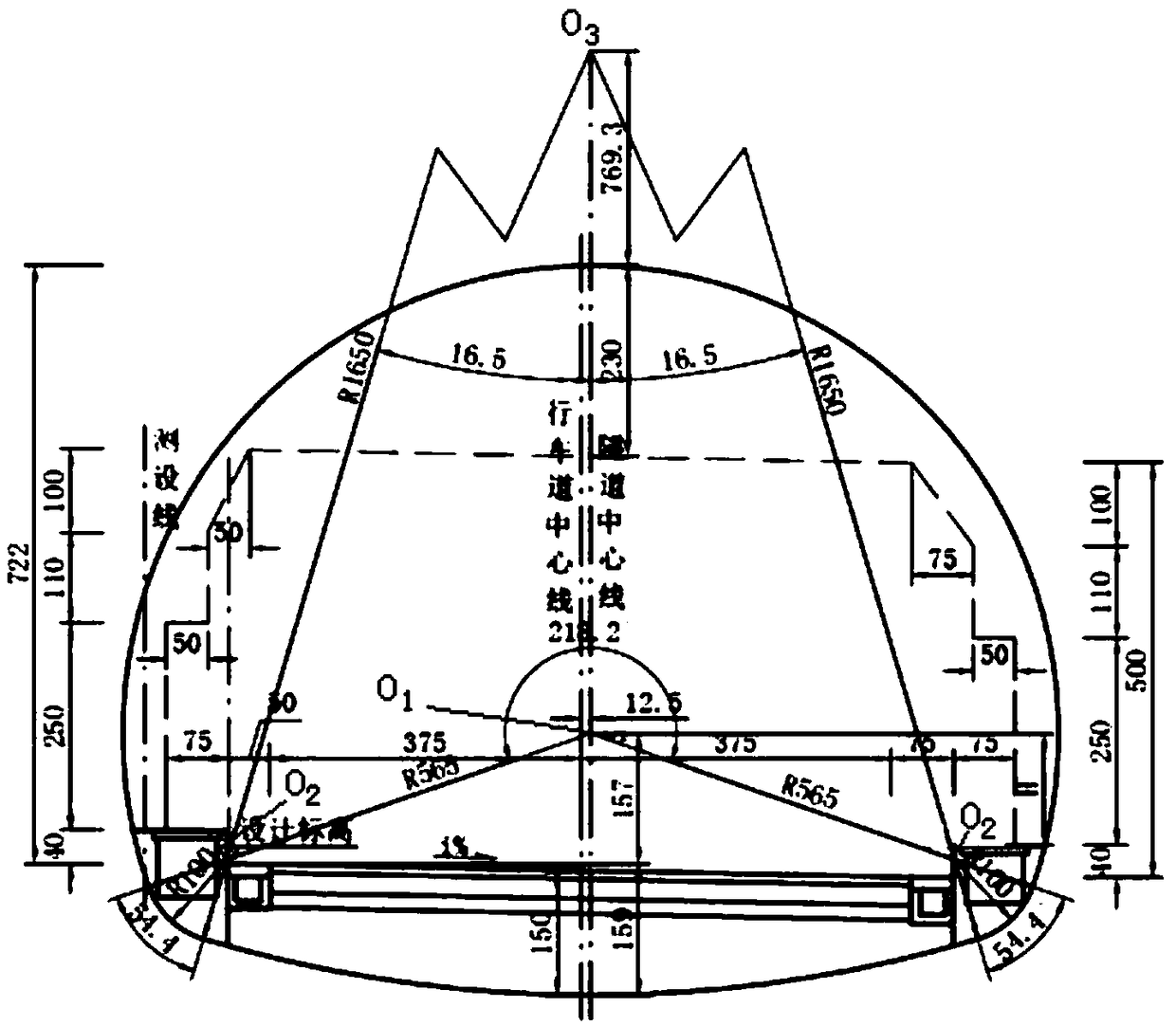

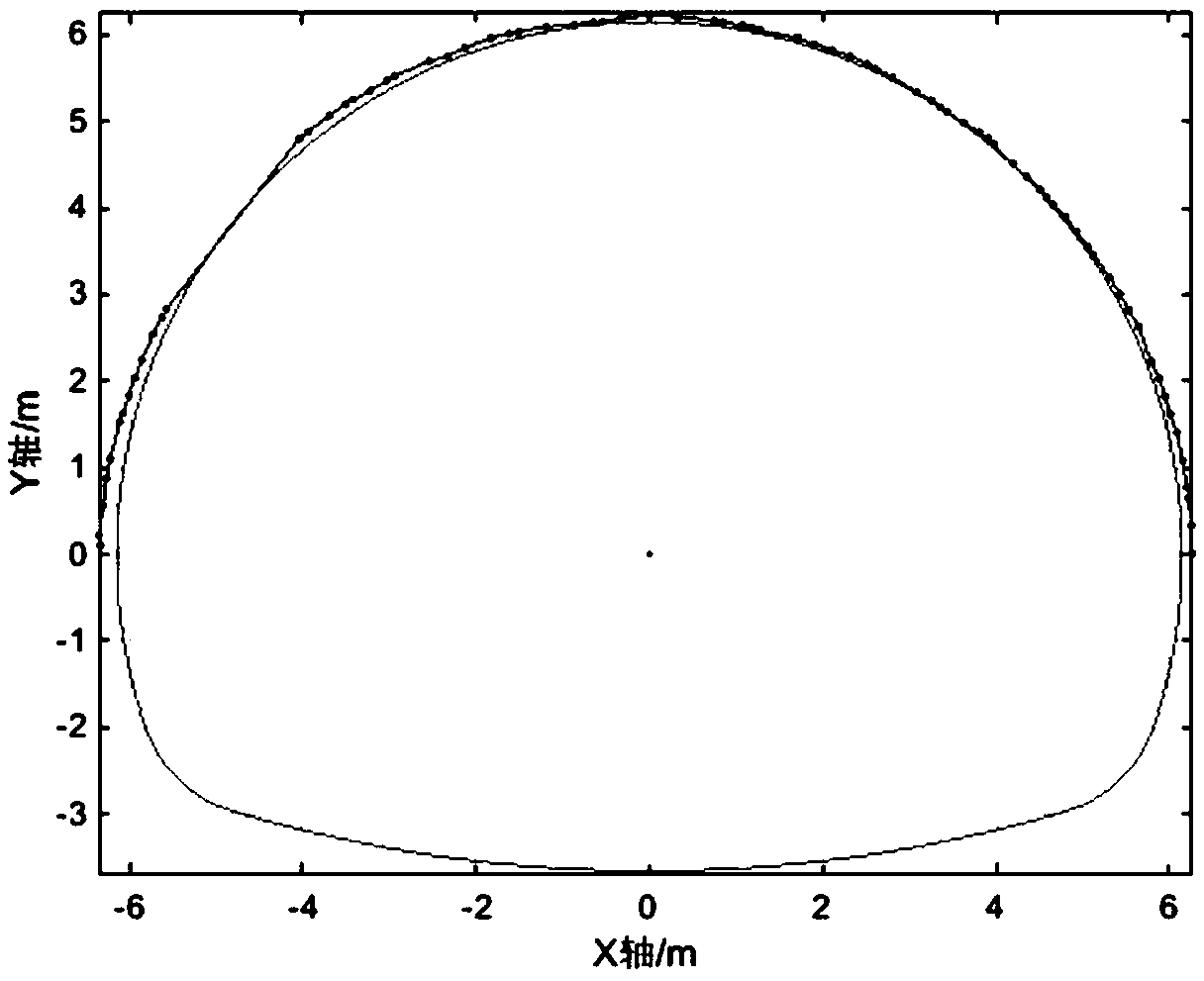

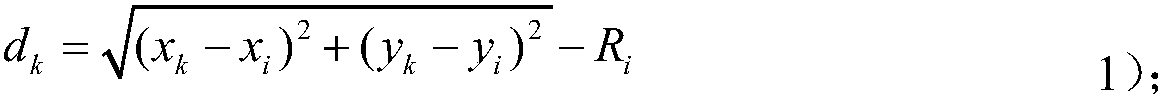

Tunnel back break numerical computation method based on laser point cloud

The invention provides a tunnel back break numerical computation method based on laser point cloud. The method comprises the following steps: obtaining the design drawing of a tunnel section profile,and establishing a plane coordinate system; calculating the circle center coordinate, radius and starting coordinate azimuth of each arc segment; obtaining the laser point cloud data of the tunnel section profile, and converting the laser point cloud data into the plane coordinate system; calculating the coordinate azimuth of each laser point cloud datum, obtaining the arc segment where the lasercloud datum is positioned, and calculating the back break numerical value of the laser point cloud datum through a unique expression formula. According to the tunnel back break numerical computation method, the calculation process is simplified, and results can be quickly obtained; the position where the laser cloud datum is positioned and the accurate back break numerical value can be accuratelyobtained, and an effective guarantee is provided for tunnel construction quality.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

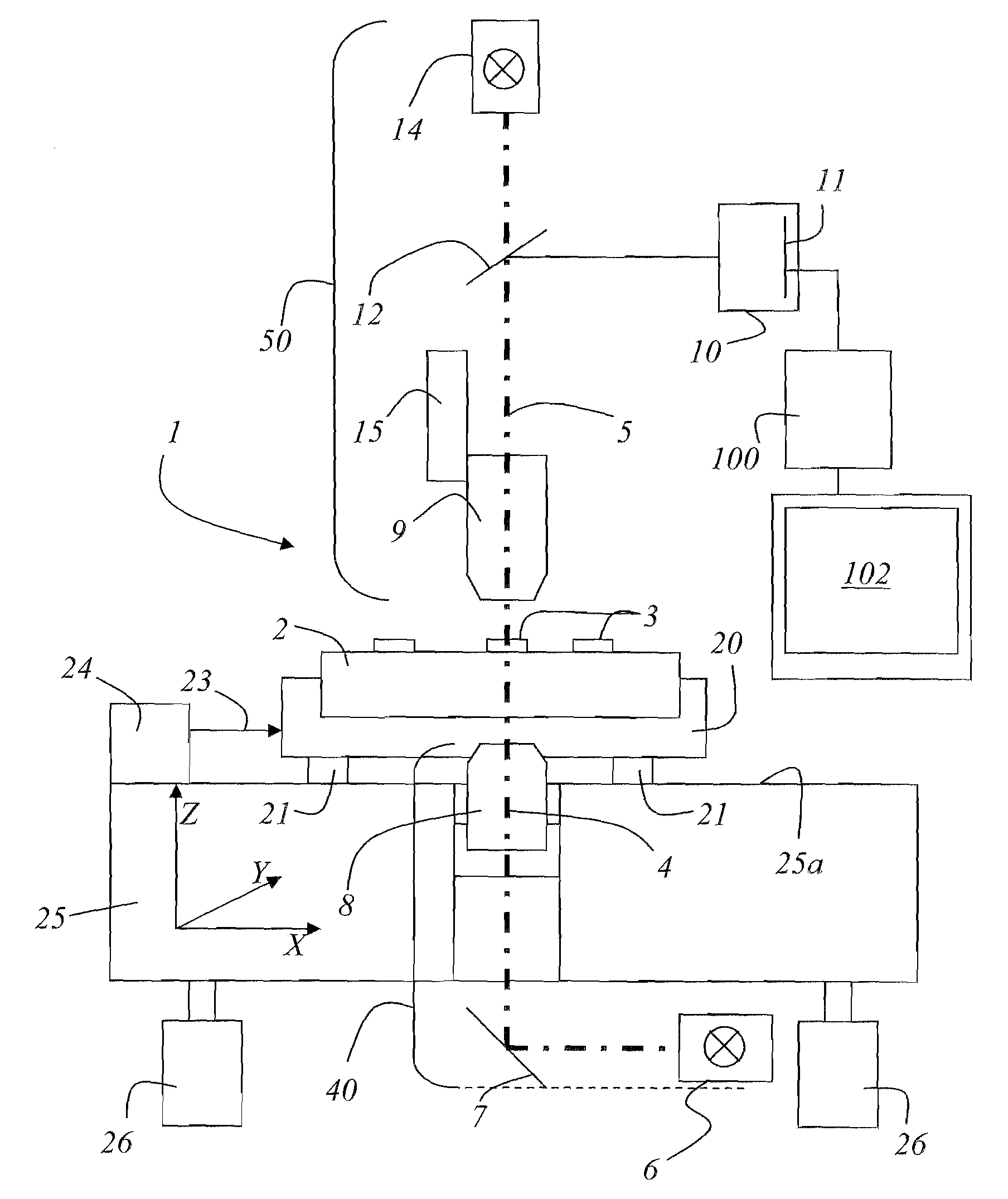

Method for eliminating sources of error in the system correction of a coordinate measuring machine

ActiveUS7694426B2Accurate measurementEliminate errorsUsing electrical meansElectric/magnetic contours/curvatures measurementsSources of errorCoordinate-measuring machine

A method is disclosed for eliminating sources of error in the system correction of a coordinate measuring machine. Herein, a number j of reference structures 33 on a rigid reference object 30 are measured in a starting orientation k=0, and the starting coordinates and the reference coordinates of the reference structures 33 on the reference object 30 are determined in a number k≧3 of mutually different orientations.

Owner:VISTEC SEMICON SYST

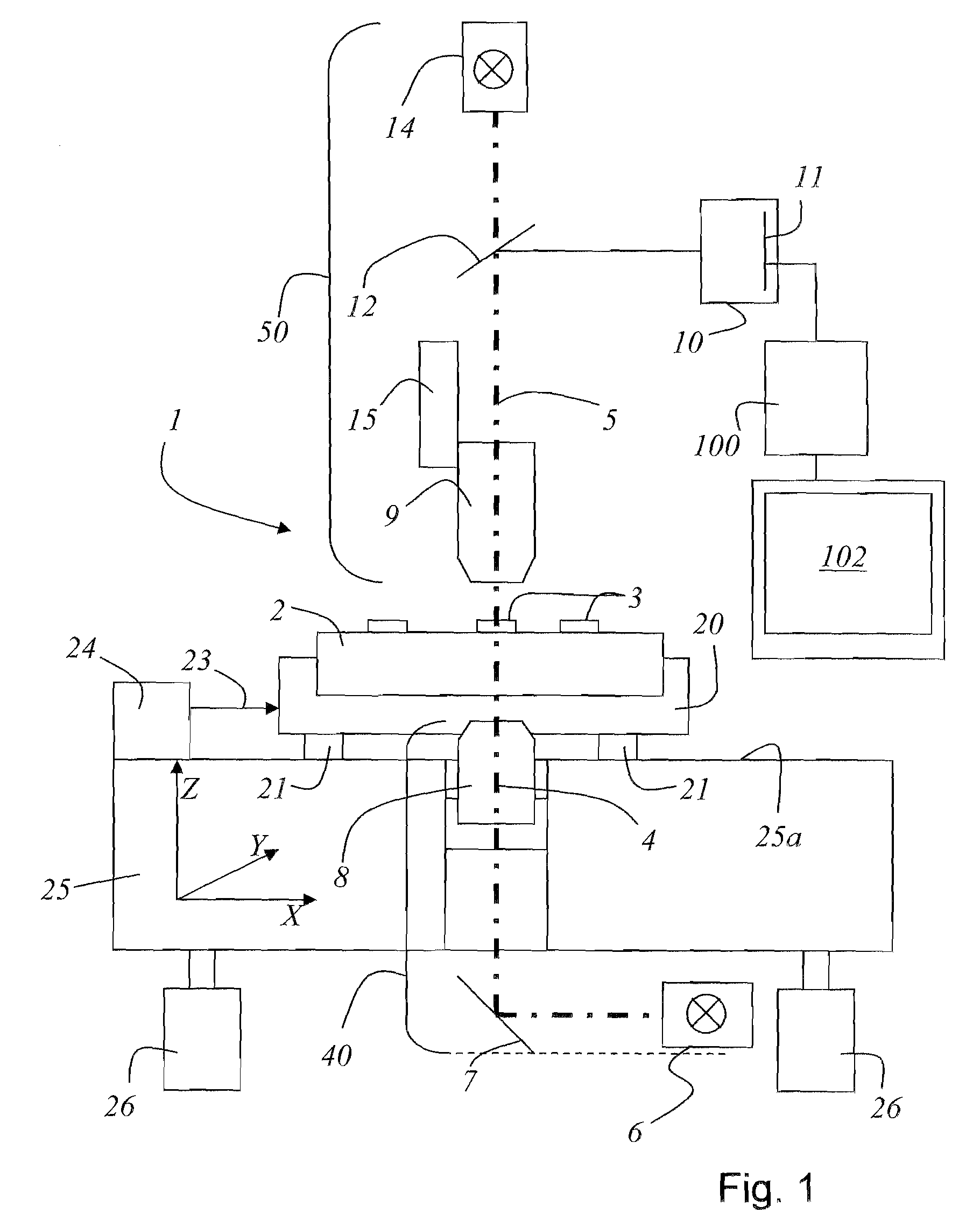

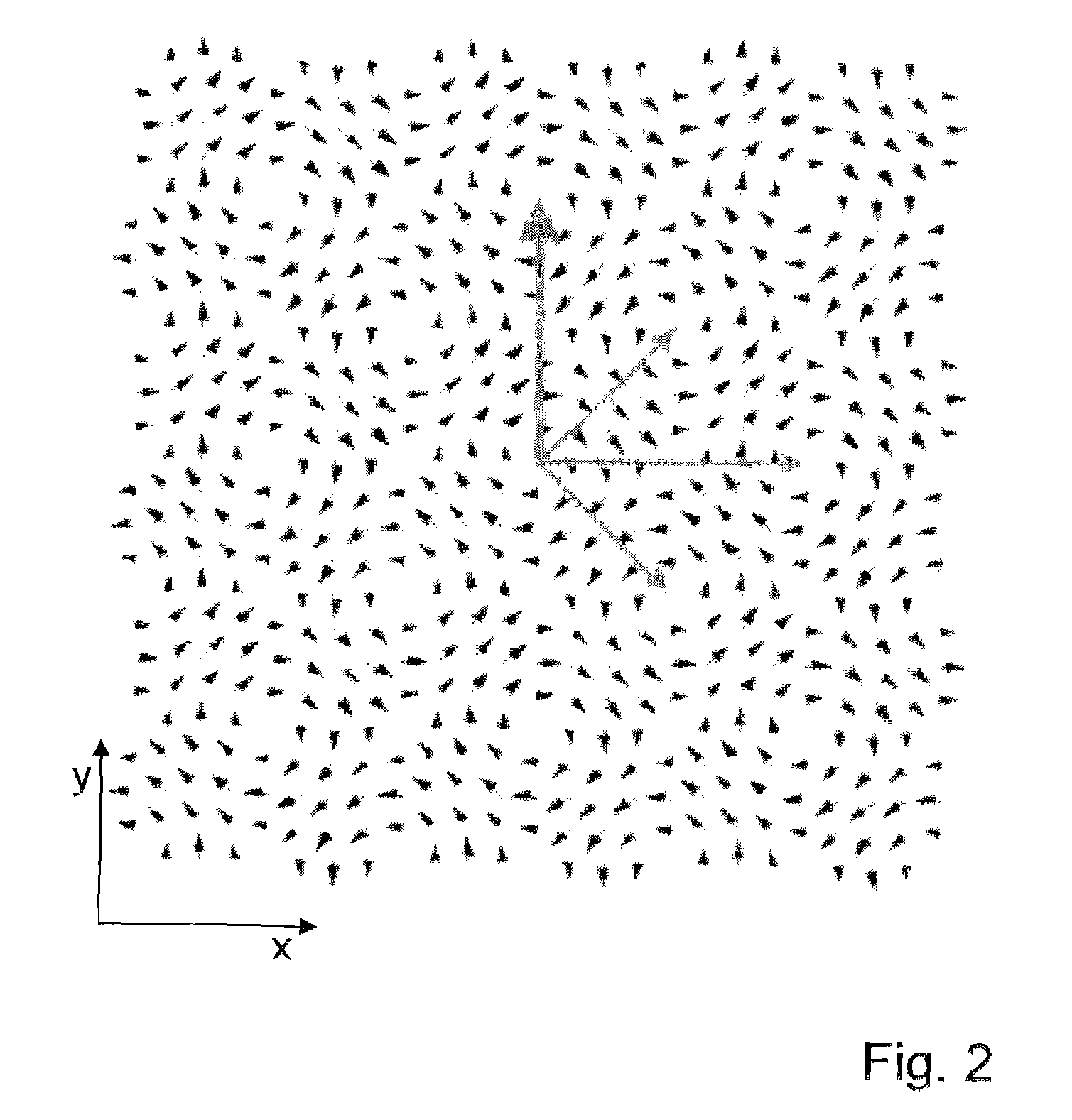

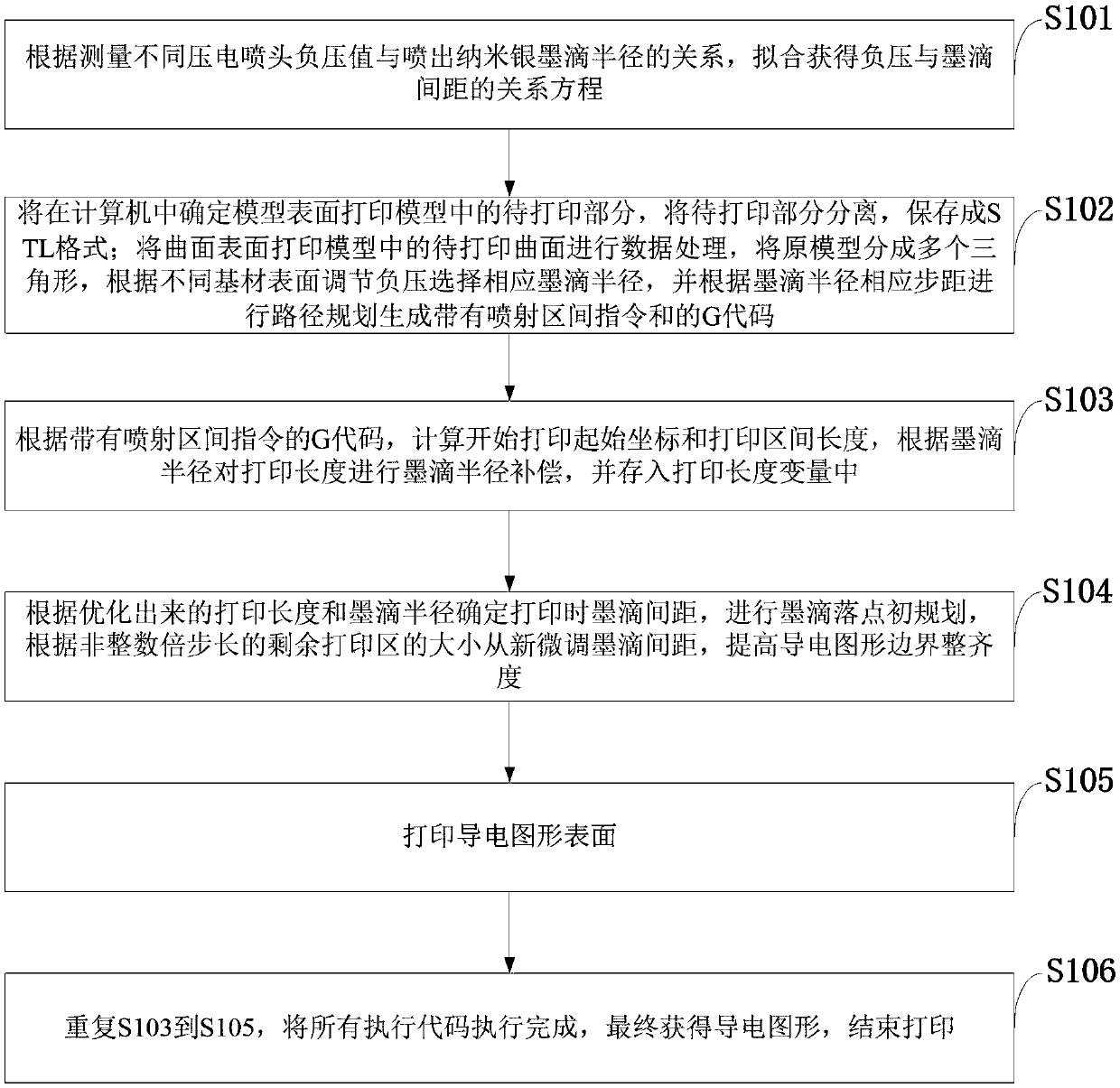

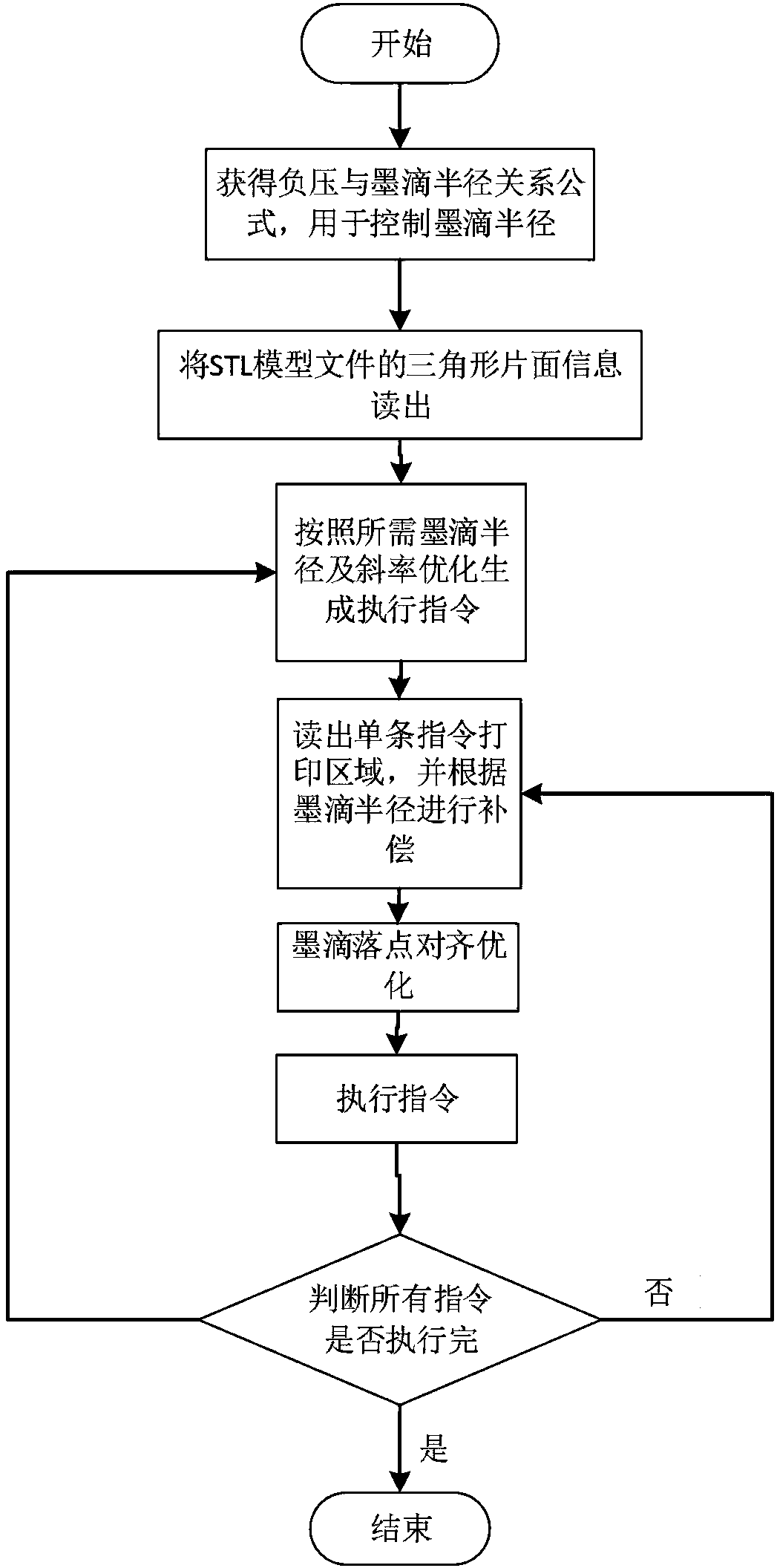

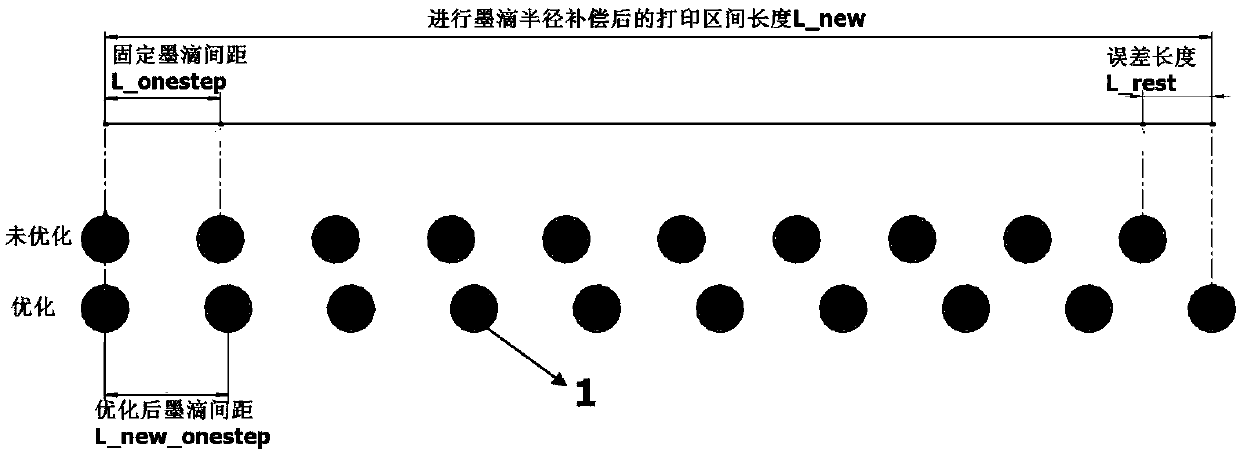

Ink droplet border aligning optimizing method for nano silver inkjet printing and printer

The invention belongs to the technical field of inkjet printing micro-manufacturing, and discloses an ink droplet border aligning optimizing method for nano silver inkjet printing and a printer. The ink droplet boarder aligning optimizing method includes the steps that a relationship equation of the negative pressure and the ink droplet distance is obtained by fitting according to measuring the relationship between negative pressure values of different piezoelectric nozzles and the radius of a jetted nano silver ink droplet; a to-be-printed part in a printing model of the model surface is determined in a computer, and the to-be-printed part is separated and stored in a STL format; a beginning printing start coordinate and the printing interval length are calculated according to a G code provided with a jet interval command, the ink droplet radius supplementation is conducted on the printing length according to the radius of the ink droplet, and the ink droplet radius is stored in printing length variable values; the ink droplet distance in the printing process is determined according to the optimized printing length and the ink droplet radius, and the ink droplet falling point initial planning is conducted; a conductive figure surface is printed; and execution of all execution codes is completed, and a conductive figure is obtained. According to different base materials, the negative pressure is adjusted so as to change the size of the ink droplet to adapt to the base materials, and thus the uniformity of the border of the conductive figure is improved effectively.

Owner:XIDIAN UNIV

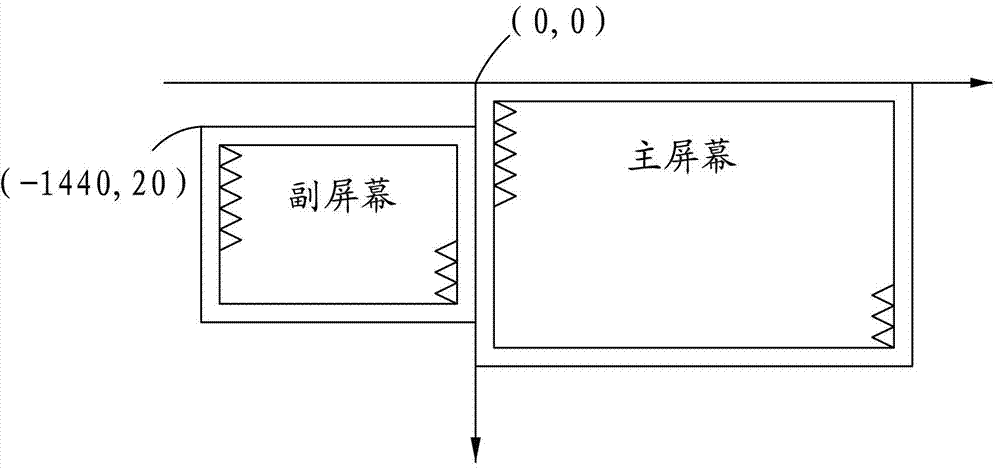

Double-board interaction implementation method on basis of electronic white boards

ActiveCN103049136AEasy to explainCathode-ray tube indicatorsDigital output to display deviceWhiteboardImage resolution

The invention provides a double-board interaction implementation method on the basis of electronic white boards. The double-board interaction implementation method includes that an electronic white board driving unit acquires the resolution and start coordinates of a main screen and the resolution and start coordinates of an auxiliary screen, the main screen and the auxiliary screen are respectively corrected by a positioning algorithm, and then an electronic white board software unit informs the electronic white board driving unit that a current service mode is a double-board interaction mode; and the electronic white board driving unit establishes a global coordinate system, when a mouse is operated on a main window of the electronic white board software unit, an analog function MOUSEEVENT of the mouse utilizes the global coordinate system for computation via an analog formula of the mouse, so that coordinates of the mouse are obtained, and mouse operation is executed. The other screen can be used for freely displaying contents for a user, double-board interaction is implemented, the user can simultaneously operate differently on the main electronic white board and the auxiliary electronic white board, the main electronic white board and the auxiliary electronic white board cannot affect each other, double-pen writing can be implemented on the main window of electronic white board software, and window dragging between the main screen and the auxiliary screen is supported.

Owner:RETURNSTAR INTERACTIVE TECH GRP

Domestic cleaning robot control method

InactiveCN106541403AAdd intelligent functionsWide coverageProgramme-controlled manipulatorFloor sweeping machinesStopped workGyroscope

The invention discloses a domestic cleaning robot control method. The domestic cleaning robot control method comprises the following steps that (1) a robot is normally in a standby sleeping status and can be awakened by a controller through two modes; (2) the robot is made to enter a pre-working mode through any awakening mode in the step (1); (3) the controller manually inputs a cleaning range, and the robot determines the working range with a start coordinate as the center; (4) the robot builds a pathfinding navigation positioning system through the indoor GPS positioning technology in cooperation with tools such as an embedded processor and a gyroscope, simulates a cleaning path, and records the cleaning path; (5) after the robot reaches a dead corner in the travelling process, a random collision mechanism is started, and the dead corner coordinate is recorded in case of repetitive collision; (6) the robot is internally provided with temperature and smoke sensors and stops working and sends out a sound-light alarm when encountering an emergency in the cleaning process; and (7) the robot returns to the starting coordinate point and enters the pre-working mode after completing a cleaning project.

Owner:HECHI UNIV

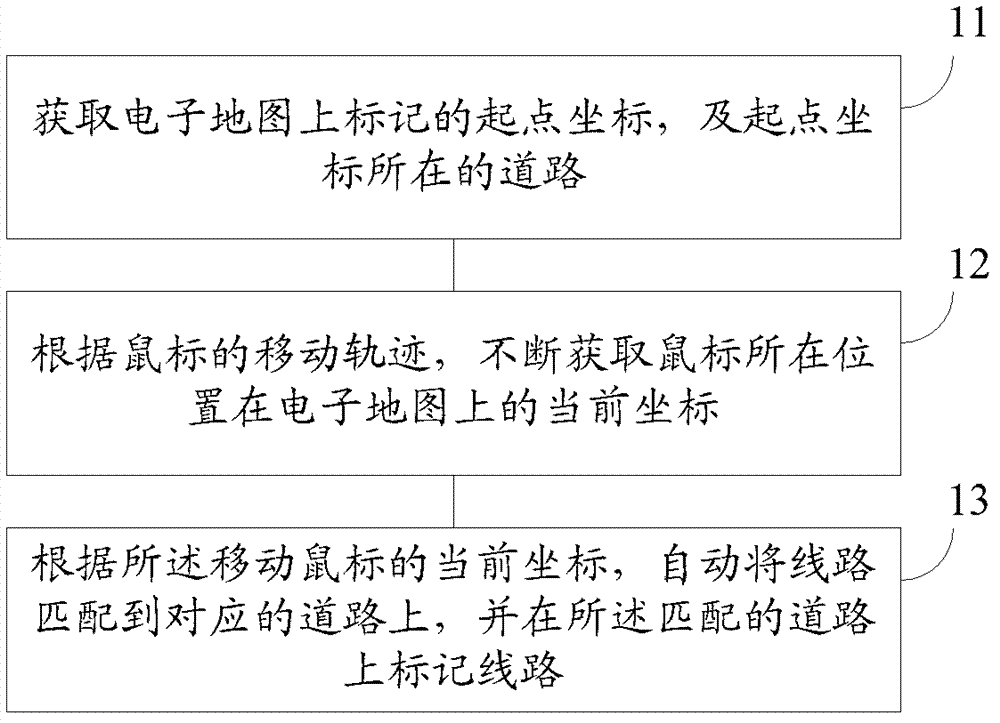

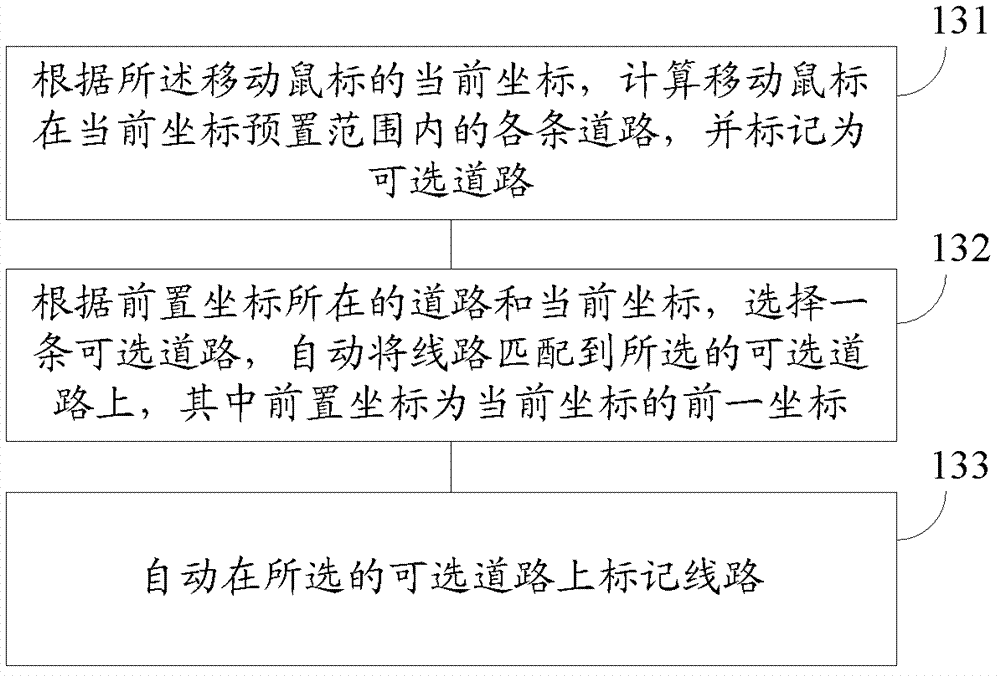

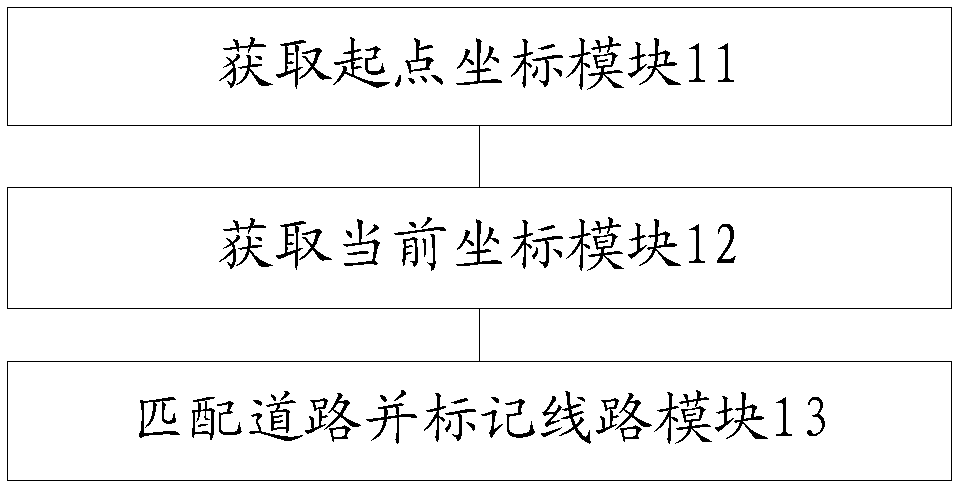

Method and system of electronic map line marking

The invention provides a method and a system of electronic map line marking. The method and the system of the electronic map line marking solve the problems that an original line marking method is complicated and costs time. The method of the electronic map line marking comprises: obtaining a starting coordinate marked on an electronic map and a road where the starting coordinate is arranged; continuously obtaining a present coordinate of a location of a mouse on the electronic map according to a moving track of the mouse; automatically matching a line with a corresponding road according to the present coordinate of the moving mouse, and marking the line on the matched road; automatically and precisely matching the line with the corresponding road according to the moving track of the mouse, and then marking the line on the road; searching the line without the need of manual map view, and manually and continuously marking every inflection point along the road so as to connect the corresponding road of a setting-out marking. The method of the electronic map line marking has the advantages of being simple, and convenient to operate, and saving time of line marking.

Owner:BEIJING TRANWISEWAY INFORMATION TECH

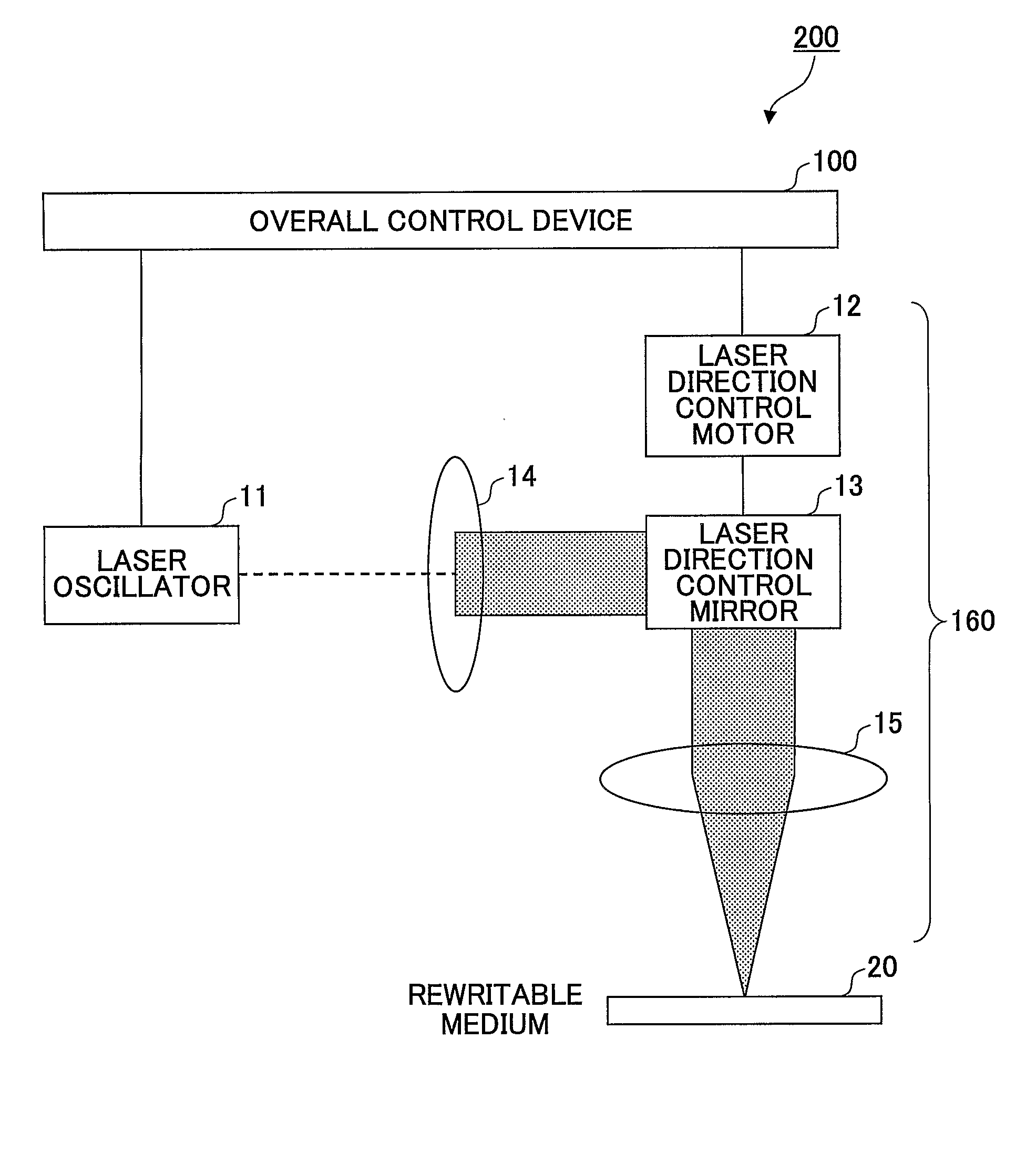

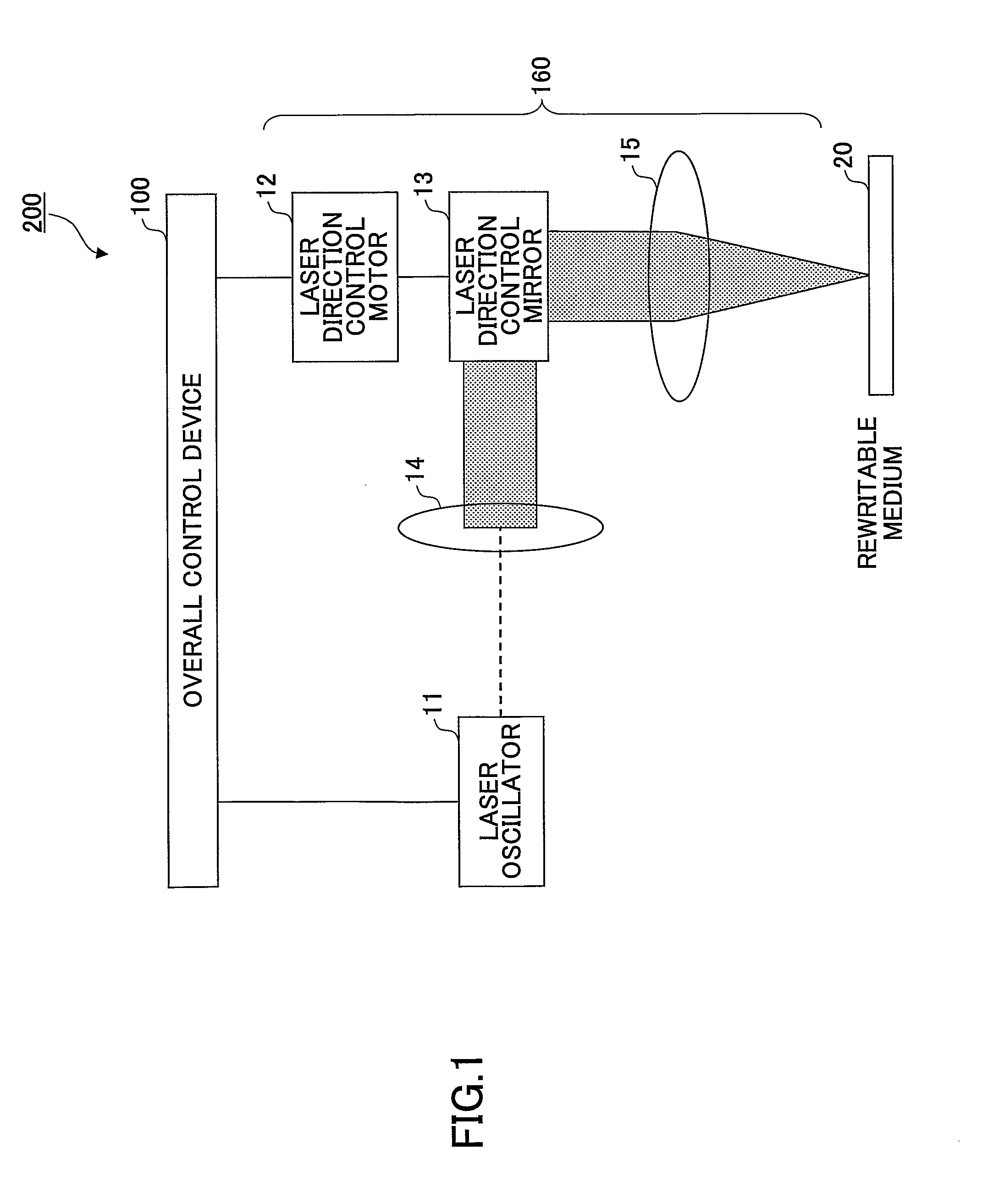

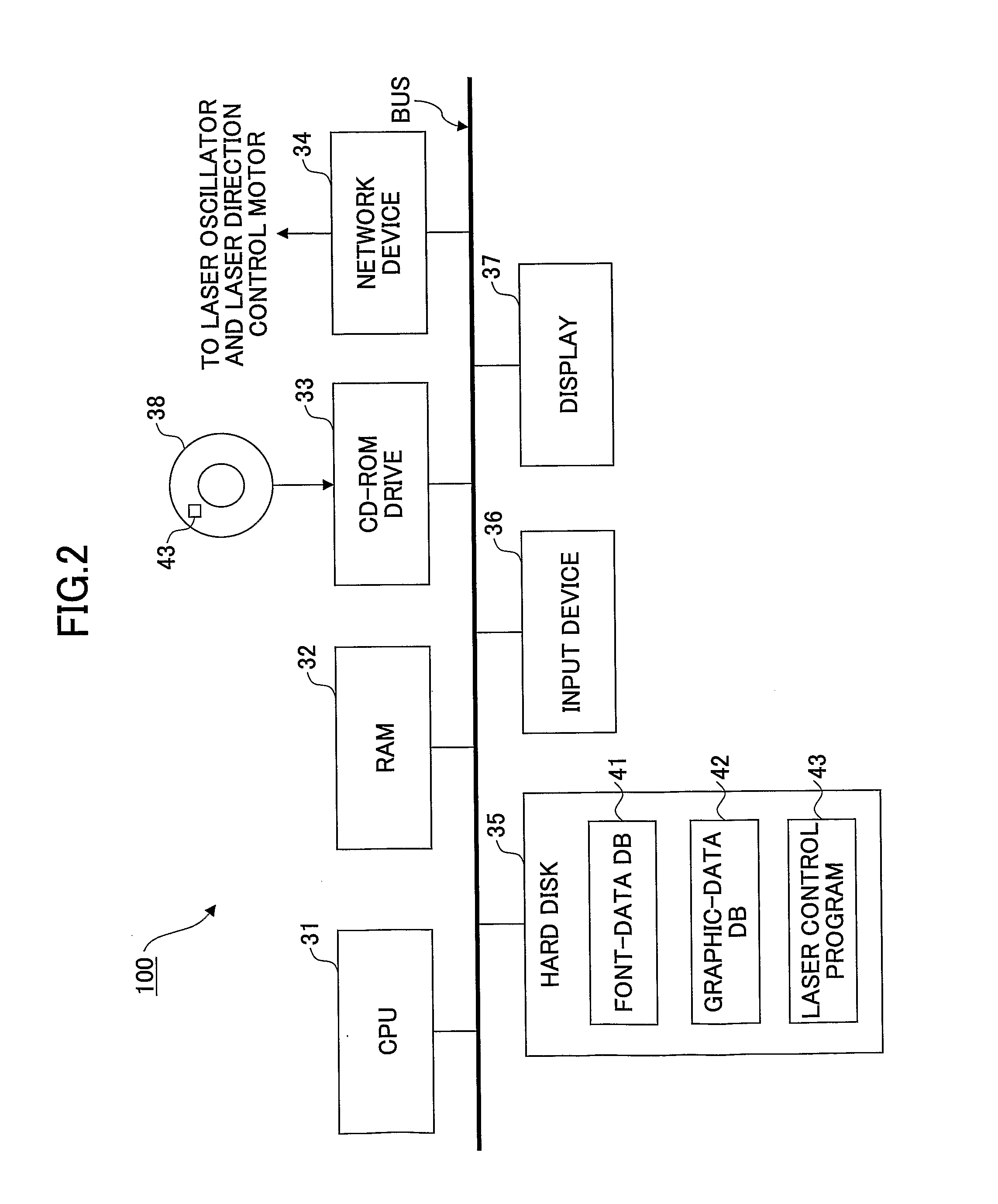

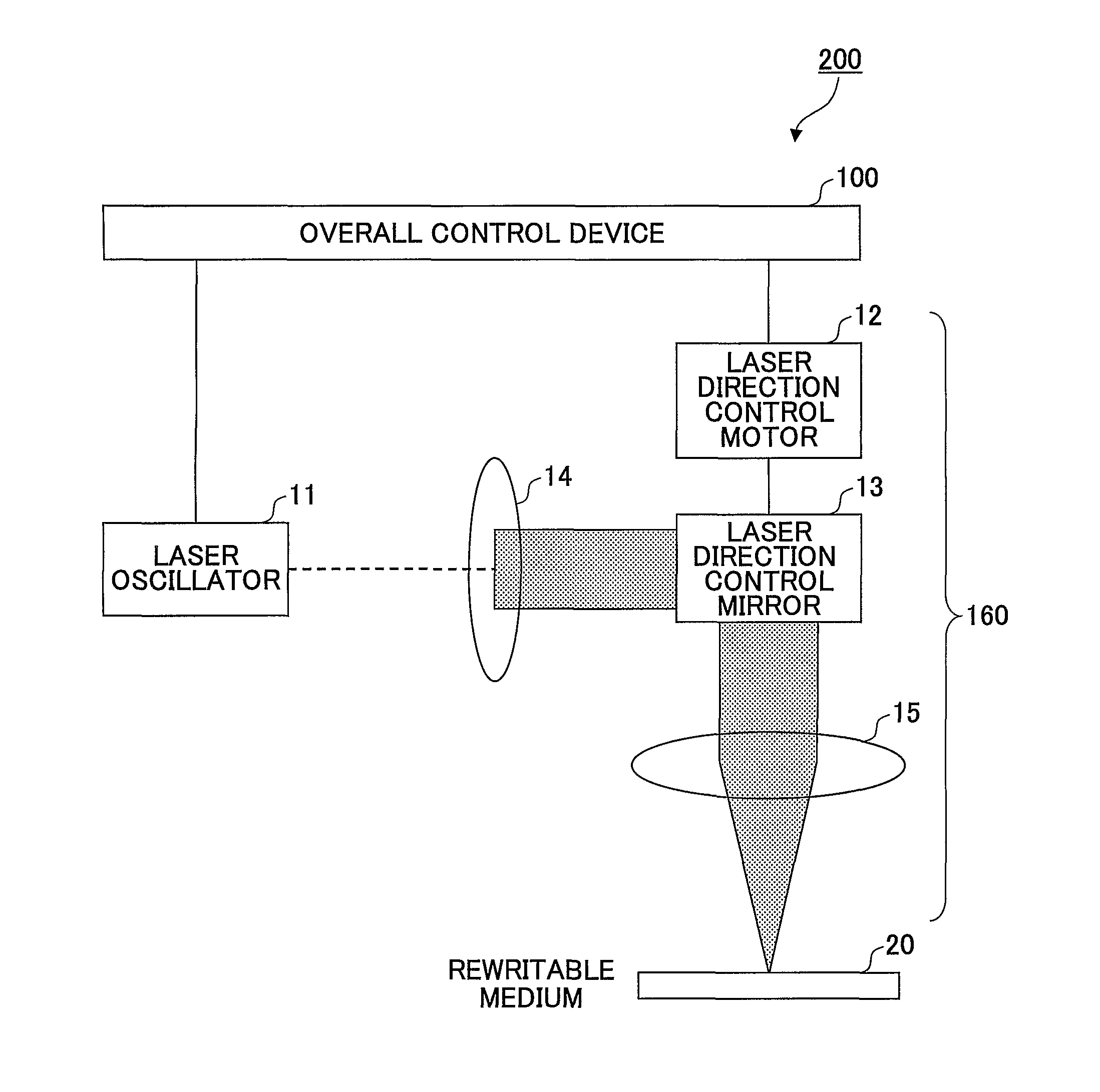

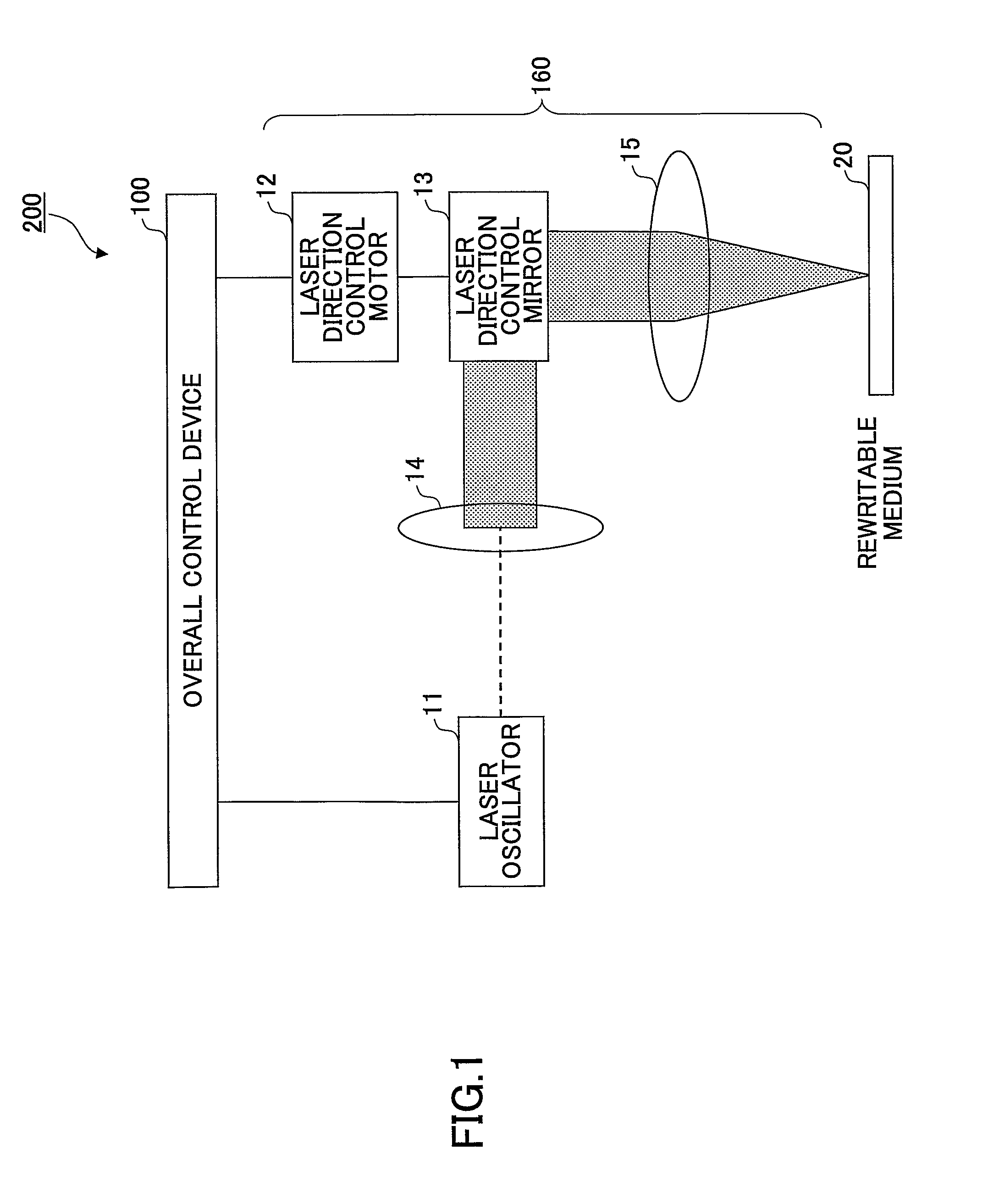

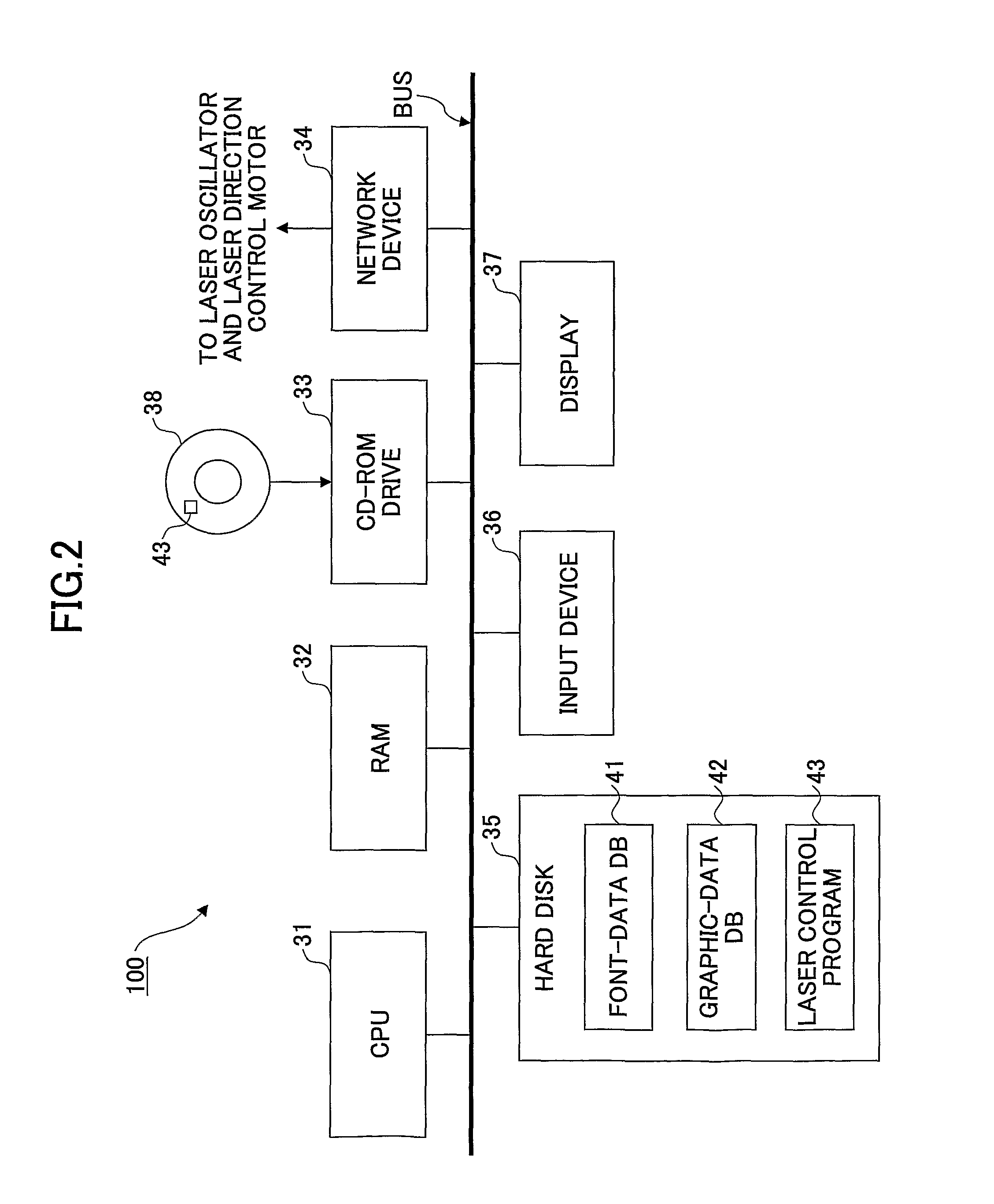

Control device, laser projection device, recording method, computer program, and recording medium

InactiveUS20110235134A1Reduce thermal interferencePrintingPictoral communicationInstruction memoryStart time

A control device includes a shape information storage storing shape information to be plotted, a stroke generation unit generating first and second stroke data having transmission start and end coordinates of first and second strokes, a scanning start time computation unit determining scanning start time of the second stroke by adjusting, when selecting first and second points having a shortest distance, a waiting time to scan the second stroke, a traveling rate from the transmission end coordinates of the first stroke to the transmission start coordinates of the second stroke, and scanning rates of scanning the first and second strokes to have a desired time interval between the selected points, a plotting instruction generation unit generating plotting instructions including the scanning start time of the second stroke and the transmission start and end coordinates of the first and second strokes, a plotting instruction storage storing the plotting instructions, and a plotting instruction execution unit executing the plotting instructions.

Owner:RICOH KK

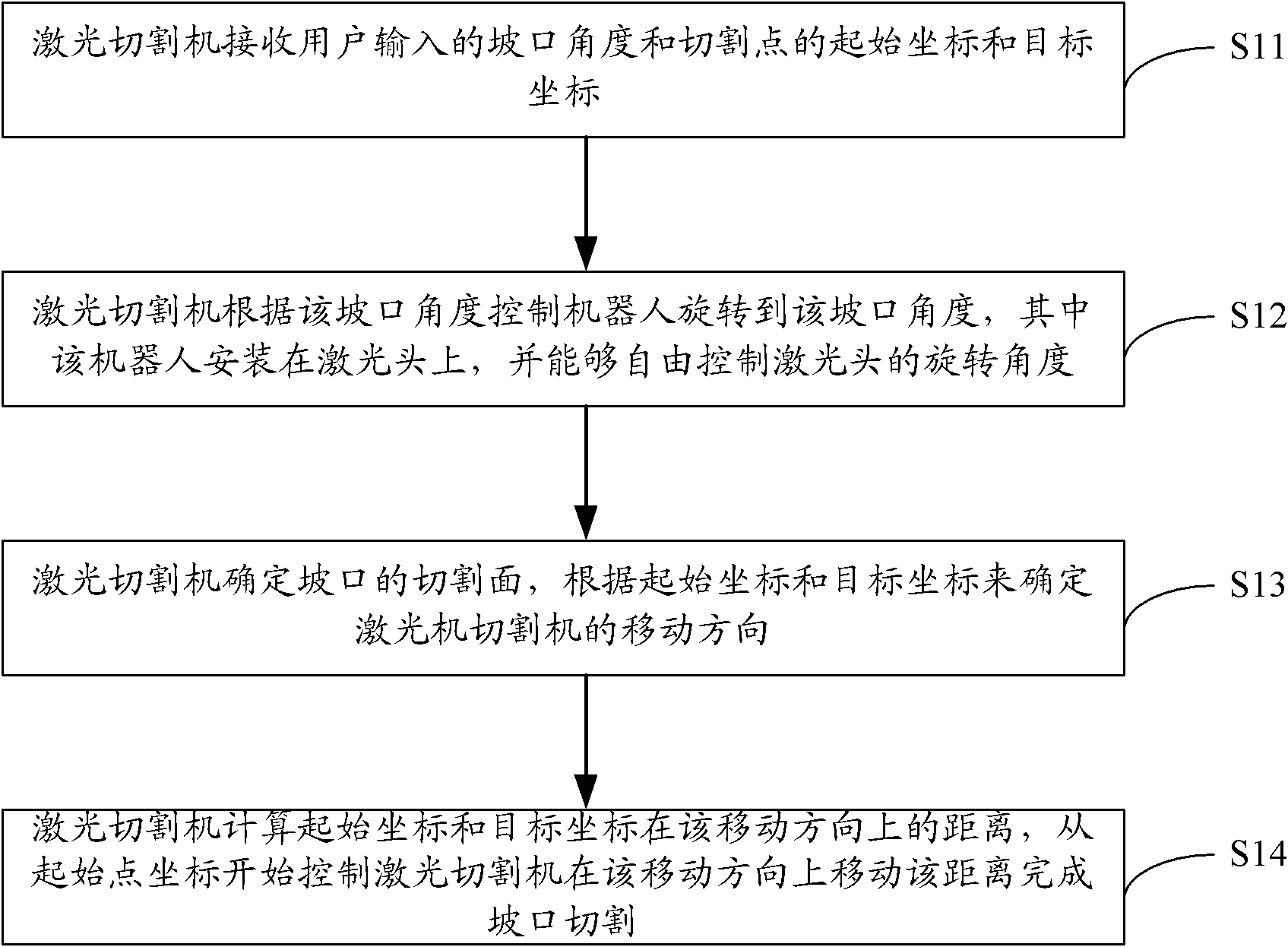

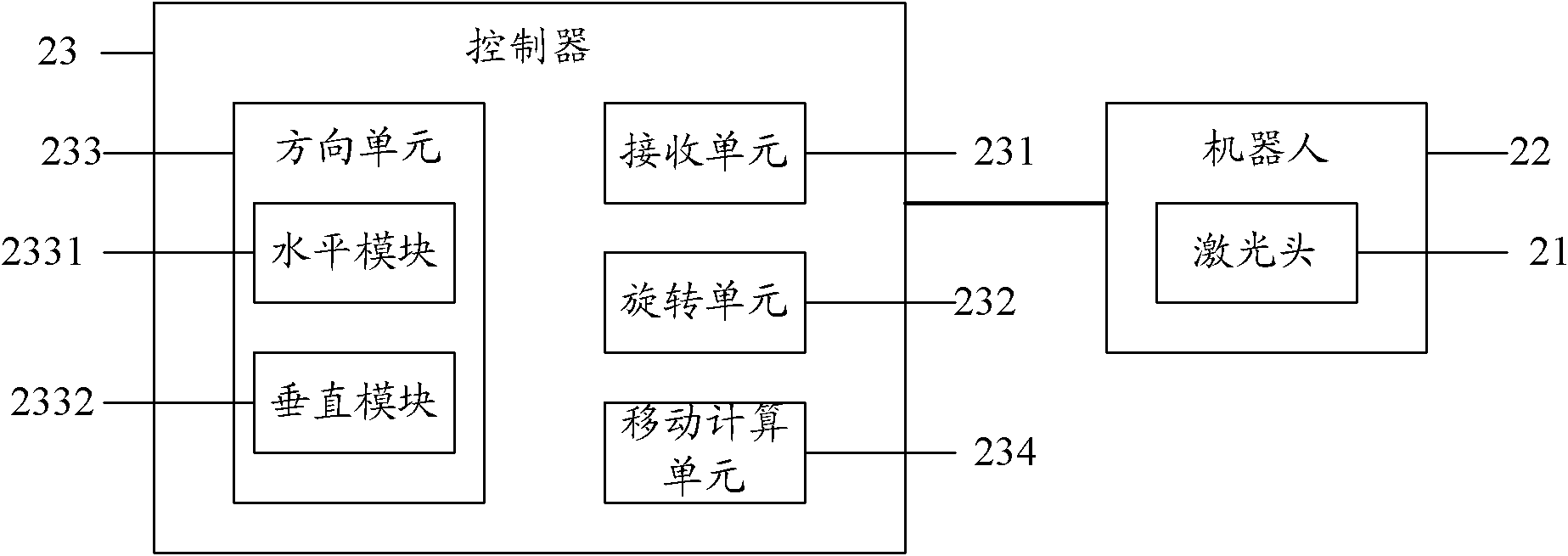

Method for cutting groove by utilizing laser and laser cutting machine

The invention is applied to the field of machining, and provides a method for cutting a groove by utilizing laser and a laser cutting machine. The method comprises the following steps that the laser cutting machine receives a groove angle and starting coordinates and destination coordinates of a cutting point from a user; the laser cutting machine controls a robot to rotate to the groove angle according to the groove angle, wherein the robot is arranged on a laser head, and can freely control a rotating angle of the laser head; the laser cutting machine determines the cut surface of the groove, and determines the movement direction of the laser cutting machine according to the starting coordinates and the destination coordinates; and the laser cutting machine calculates a distance between the starting coordinates and the destination coordinates in the movement direction, and is controlled to move for the distance in the movement direction from the starting coordinates to finish cutting the groove. The technical scheme has the advantage of capability of cutting the groove.

Owner:SHENZHEN HANS MP LASER TECH CO LTD

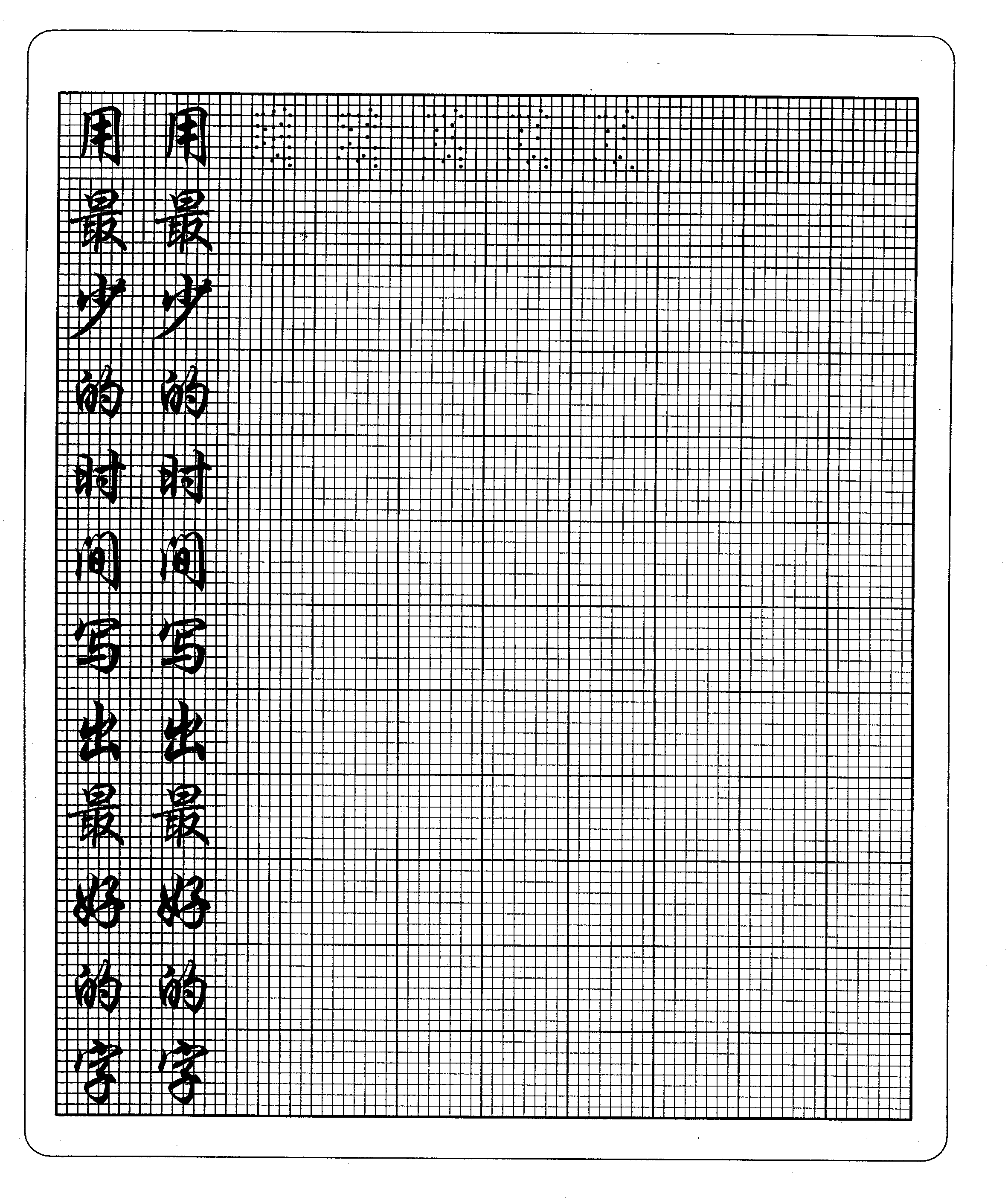

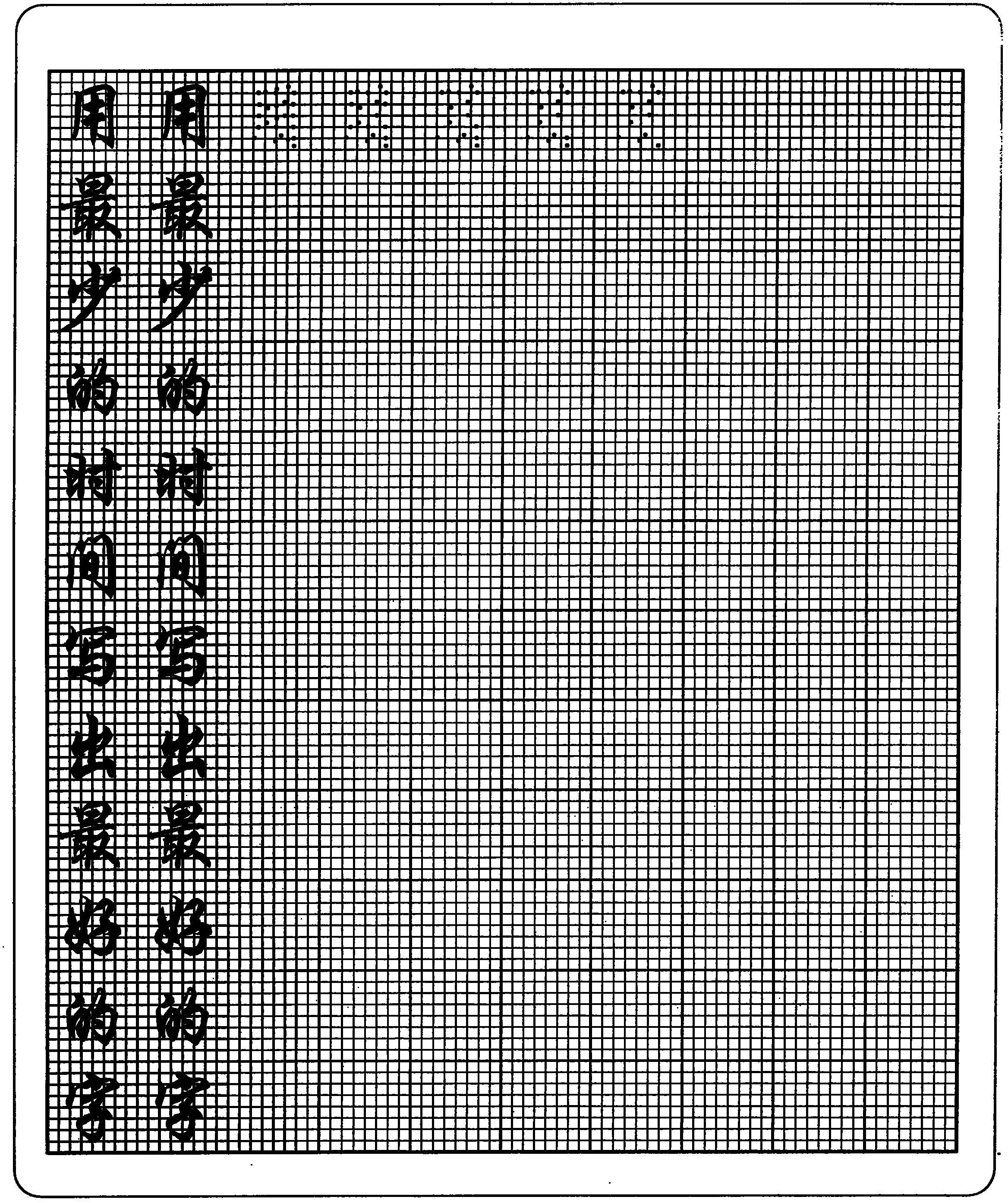

Character and graph writing exercise book

InactiveCN102222426AIncrease interest in practiceEasy to compileTeaching apparatusGraphicsEngineering

The invention discloses a character and graph writing exercise book. As for the exercise book, each grid in the inner sheet is provided with eight colorful straight lines, the mutually perpendicular colorful straight lines can cover characters and graphs in 64 grids to determine the coordinate positions of the strokes of the characters and graphs, the first line and second line at the left side of the inner sheet of the exercise book are printed with characters and graphs, the third line is printed with a few of coordinates on running tracks of the strokes of the characters and graphs, the coordinates on the running track of each stroke in the fourth line are one less than those in the third line, and by parity of reasoning, one coordinate is reduced line by line until each stroke only has a starting coordinate and a terminating coordinate and the residual lines are blank spaces. By adopting the characters and graphs in the exercise book to take writing training step by step, and combining with the methods of tracks, coordinates, gugyeol and the like in the training, a practicer can master the structures of the characters and graphs in a short period of time, thus rapidly forming a dynamic stereotype with correct writing tracks, and turning complicated, boring and inefficient calligraphy practice into simple, interesting and efficient learning activity.

Owner:周筑先 +1

A Drilling Method of CNC Milling Machine with Tilting Spindle

The invention provides a drilling method for a numerically controlled milling machine with a tiltable spindle. First, clamp the workpiece to be drilled on the machine tool; tilt the machine tool spindle around the Y-axis of the machine tool coordinate system according to the processing requirements, and use a sine gauge to verify the tilt angle, so that the machine tool spindle is perpendicular to the surface to be drilled; secondly, clamp the drill bit on the machine tool spindle, And control the rapid feed of the drill bit, so that the drill tip moves to the position of the hole top, and determine the coordinates (x0, y0, z0) of the hole top in the machining coordinate system; take (x0, y0, z0) as the coordinates of the first drilling start point , according to the determination of the coordinates (x1, y1, z1) of the end point of one drilling, where l is the moving distance of the drill bit along the drilling direction; the drill bit is retracted after one drilling, and then the end point coordinates of the previous drilling are used as the new The coordinates of the starting point of a drilling cycle are carried out until the hole depth meets the processing requirements. The method realizes the drilling processing task that cannot be completed by the ordinary numerical control milling machine under the working condition with poor openness, and at the same time, the required cost is also greatly reduced compared with the five-coordinate machining center.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Control device, laser projection device, recording method, computer program, and recording medium

A control device includes a shape information storage storing shape information to be plotted, a stroke generation unit generating first and second stroke data having transmission start and end coordinates of first and second strokes, a scanning start time computation unit determining scanning start time of the second stroke by adjusting, when selecting first and second points having a shortest distance, a waiting time to scan the second stroke, a traveling rate from the transmission end coordinates of the first stroke to the transmission start coordinates of the second stroke, and scanning rates of scanning the first and second strokes to have a desired time interval between the selected points, a plotting instruction generation unit generating plotting instructions including the scanning start time of the second stroke and the transmission start and end coordinates of the first and second strokes, a plotting instruction storage storing the plotting instructions, and a plotting instruction execution unit executing the plotting instructions.

Owner:RICOH KK

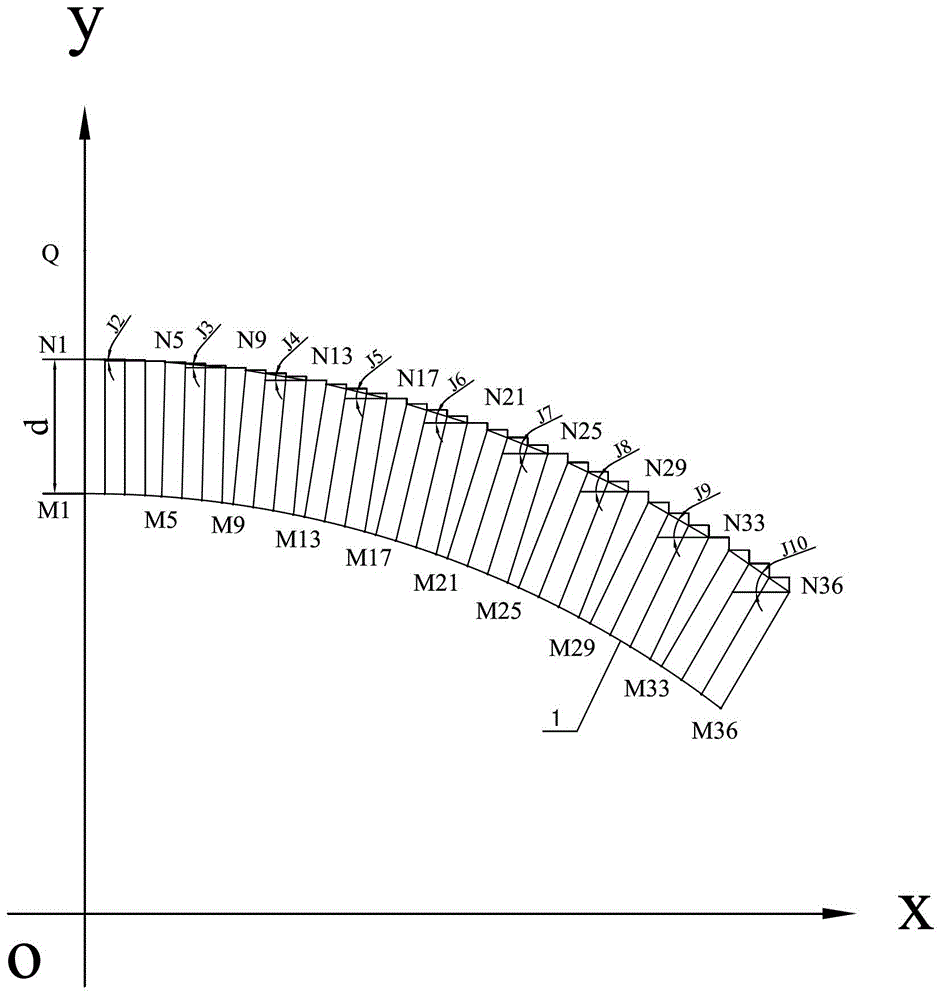

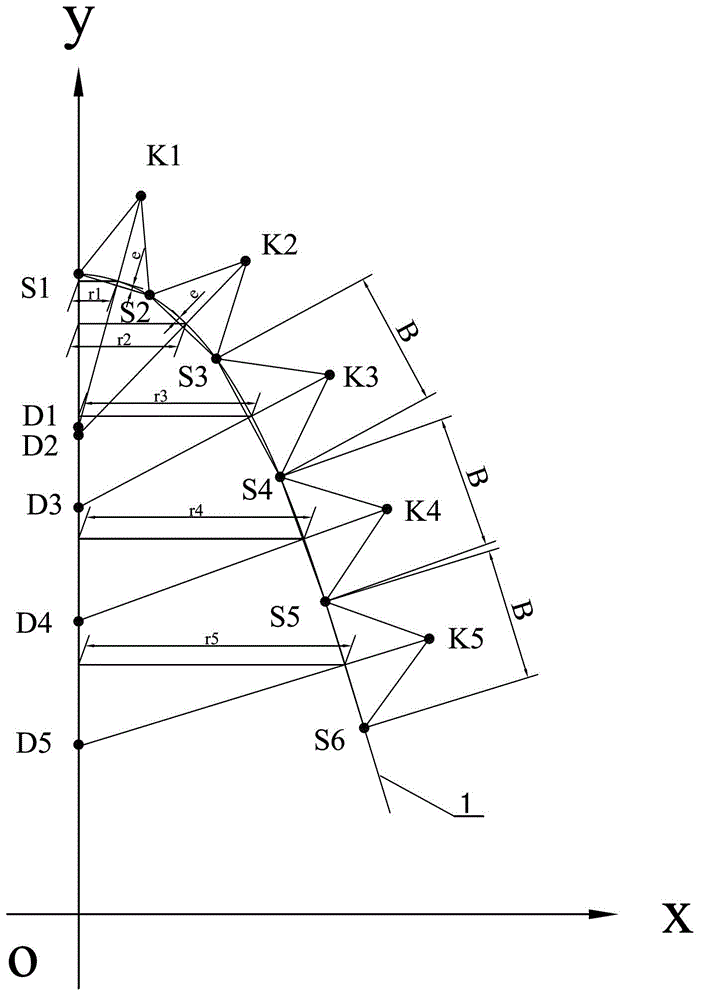

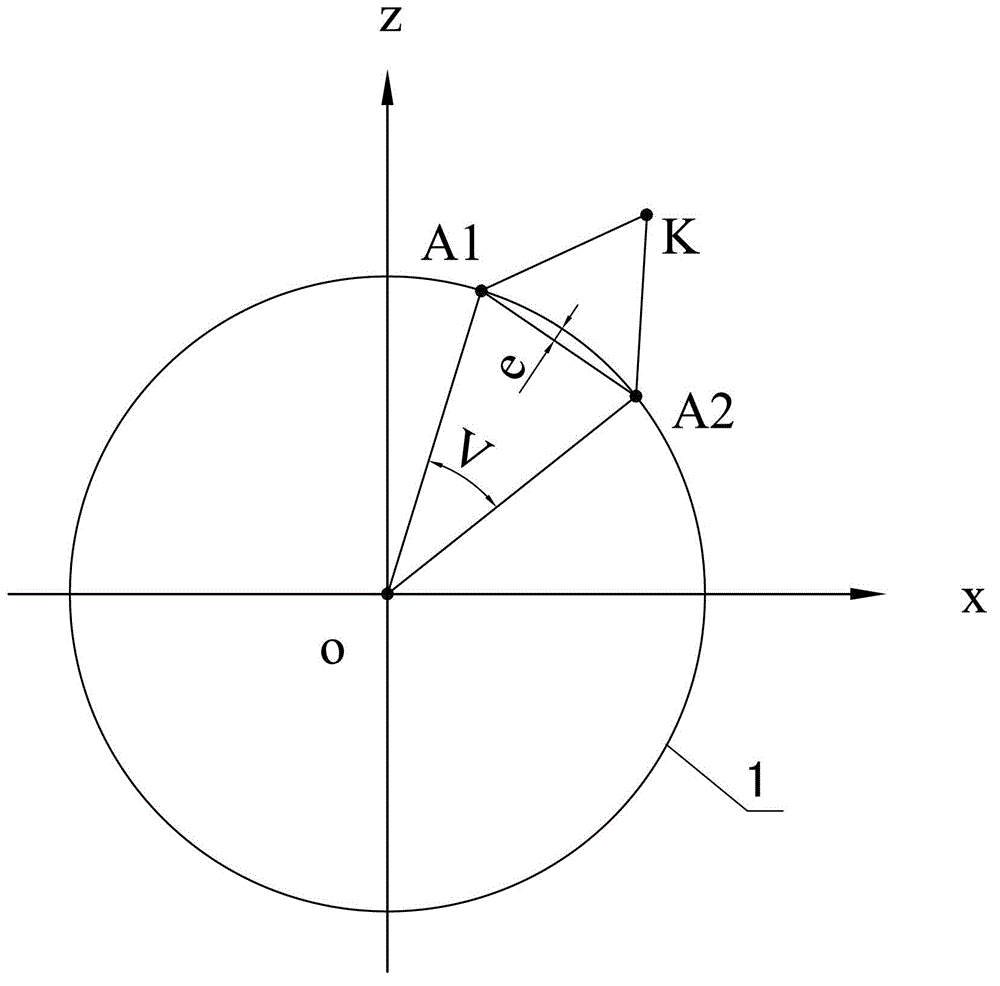

Light transmission scanning-detecting controlling method for ceramic antenna cover

InactiveCN102749884AThe test result is accurateThe test results are objectiveOptically investigating flaws/contaminationNumerical controlLaser rangingMovement control

The invention relates to a light transmission scanning-detecting controlling method for a ceramic antenna cover. The light transmission scanning-detecting controlling method comprises the following steps of: (1) locating a coordinate position of a starting point of a laser ranging image collection head; (2) measuring a starting coordinate position of a scanning control point through focusing; (3) determining a coordinate position of the scanning control point of an antenna cover and a scanning incidence angle according to a method selected by track calculation and equal error control points; (4) calculating a light source coordinate moving position according to the scanning incidence angle of each scanning control point; (5) carrying out compiling of a scanning control NC program on a scanning path, a scanning incidence angle and a light source according to a line point position control mode; (6) calculating according to a visual angle of a laser ranging image acquisition head and a scanning row central section outer edge curve to compile a circular scanning NC program; and (7) controlling the laser ranging image acquisition head to carry out image acquisition on the antenna cover and carry out processing and analyzing to obtain crack and loose texture defect parameters of the ceramic antenna cover to be used for quality judgment.

Owner:SHANDONG UNIV OF TECH

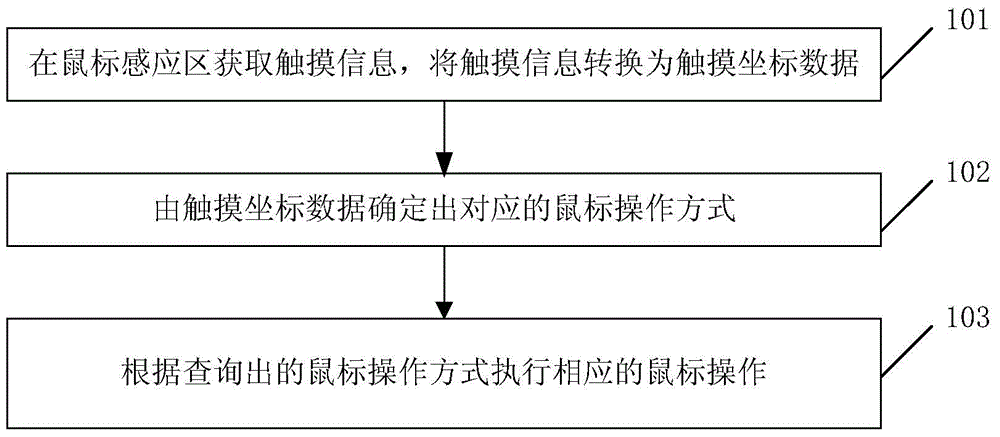

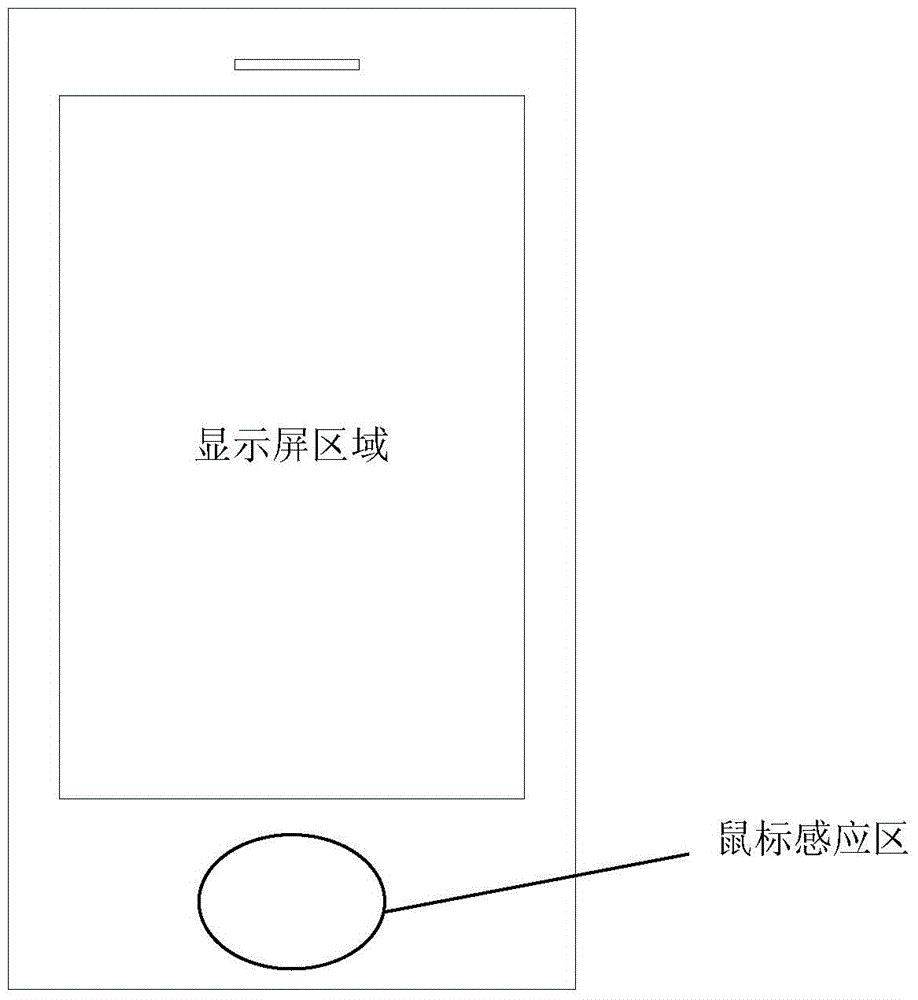

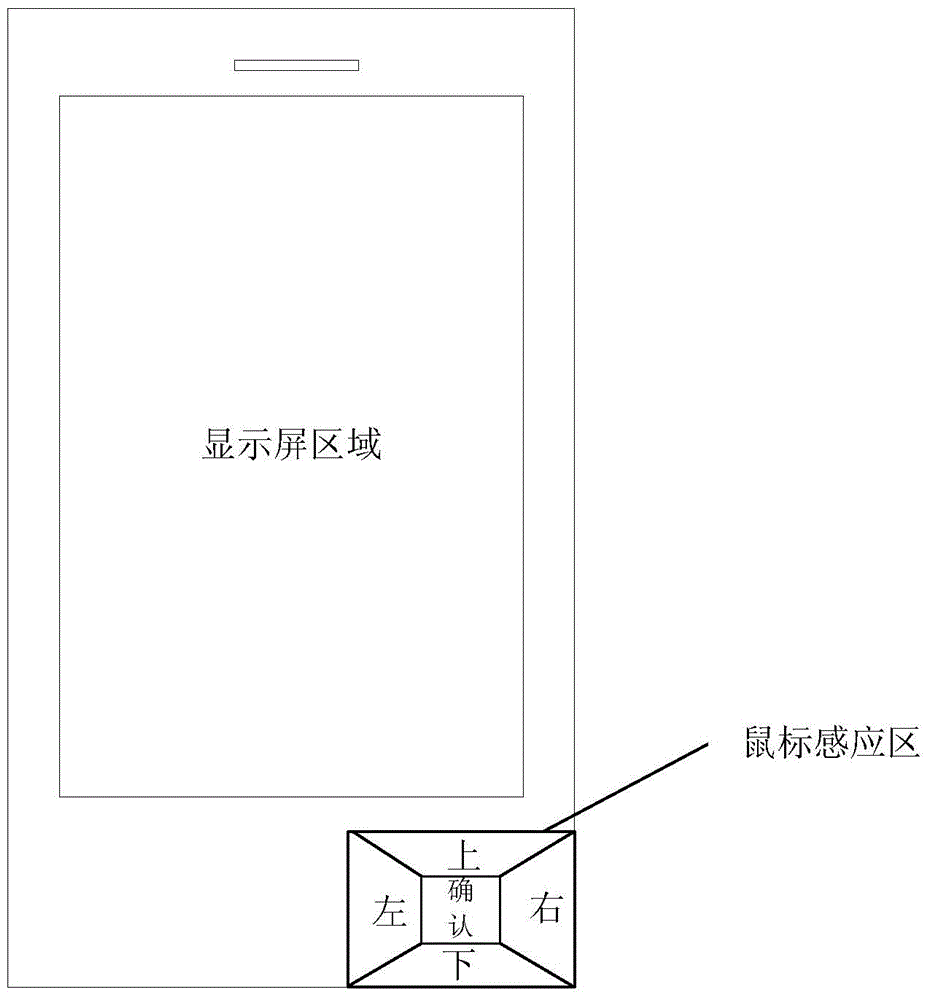

Mobile terminal and touch method thereof

InactiveCN104102385AEasy to operateEasy to controlInput/output processes for data processingInformation transformationReal-time computing

The invention discloses a mobile terminal and a touch method thereof. The touch method includes: setting a mouse sensing area in a local range below a touch display area of the mobile terminal; acquiring touch information from the mouse sensing area and converting the touch information into touch coordinate data; determining a corresponding mouse operating mode according to the touch coordinate data; when the touch information is slide information, with the touch coordinate data including start coordinates and stop coordinates of a slide, determining that changes in horizontal ordinates of the start coordinates and the stop coordinates are larger than a horizontal slide threshold, and determining that a mouse is operated in a horizontal sliding manner; executing a corresponding mouse operation according to the queried mouse operating mode. The mobile terminal and the touch method thereof according to the scheme have the advantages that mouse control can be performed in the local range below the touch display area of a panel of the mobile terminal and operation is facilitated.

Owner:QISDA SUZHOU

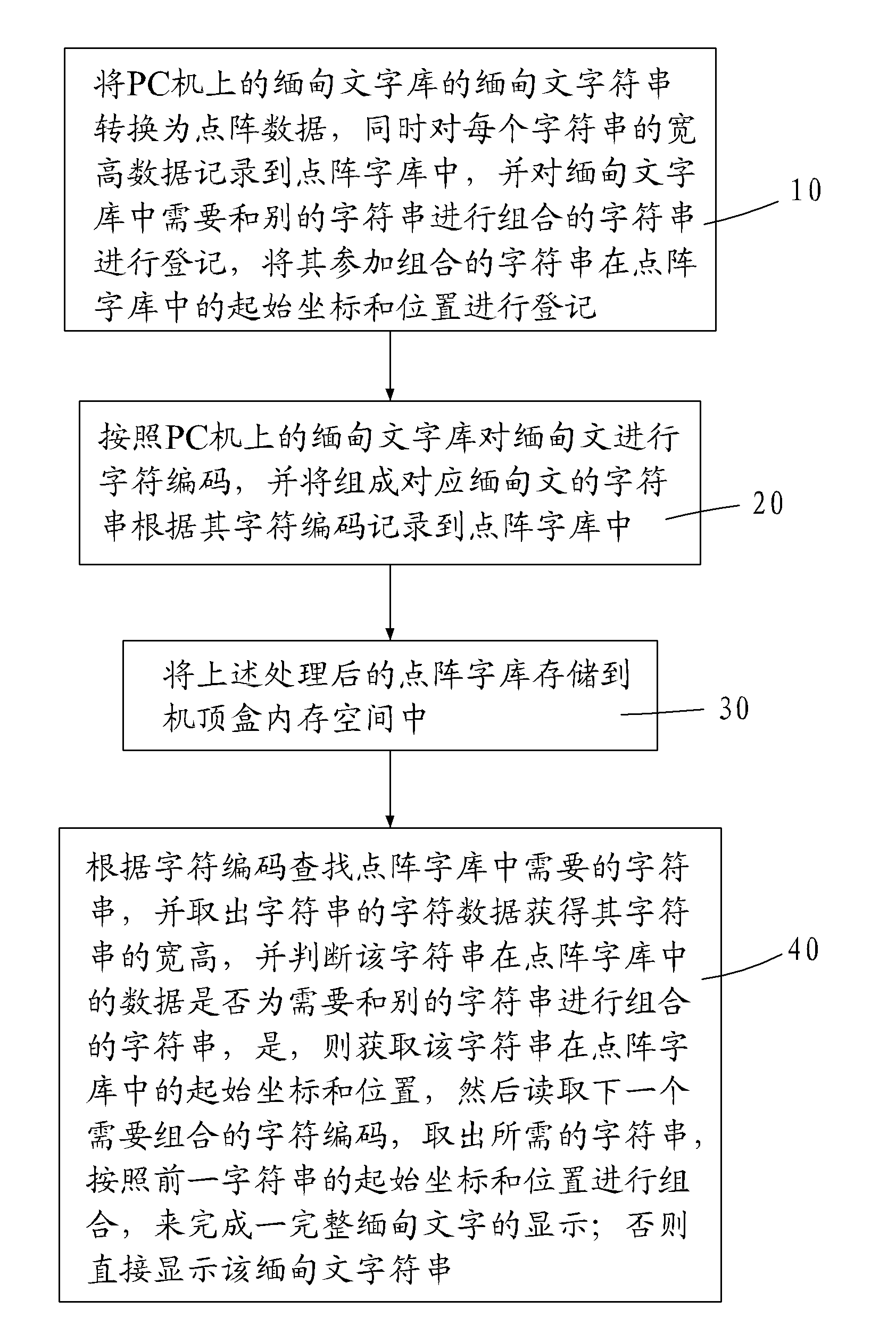

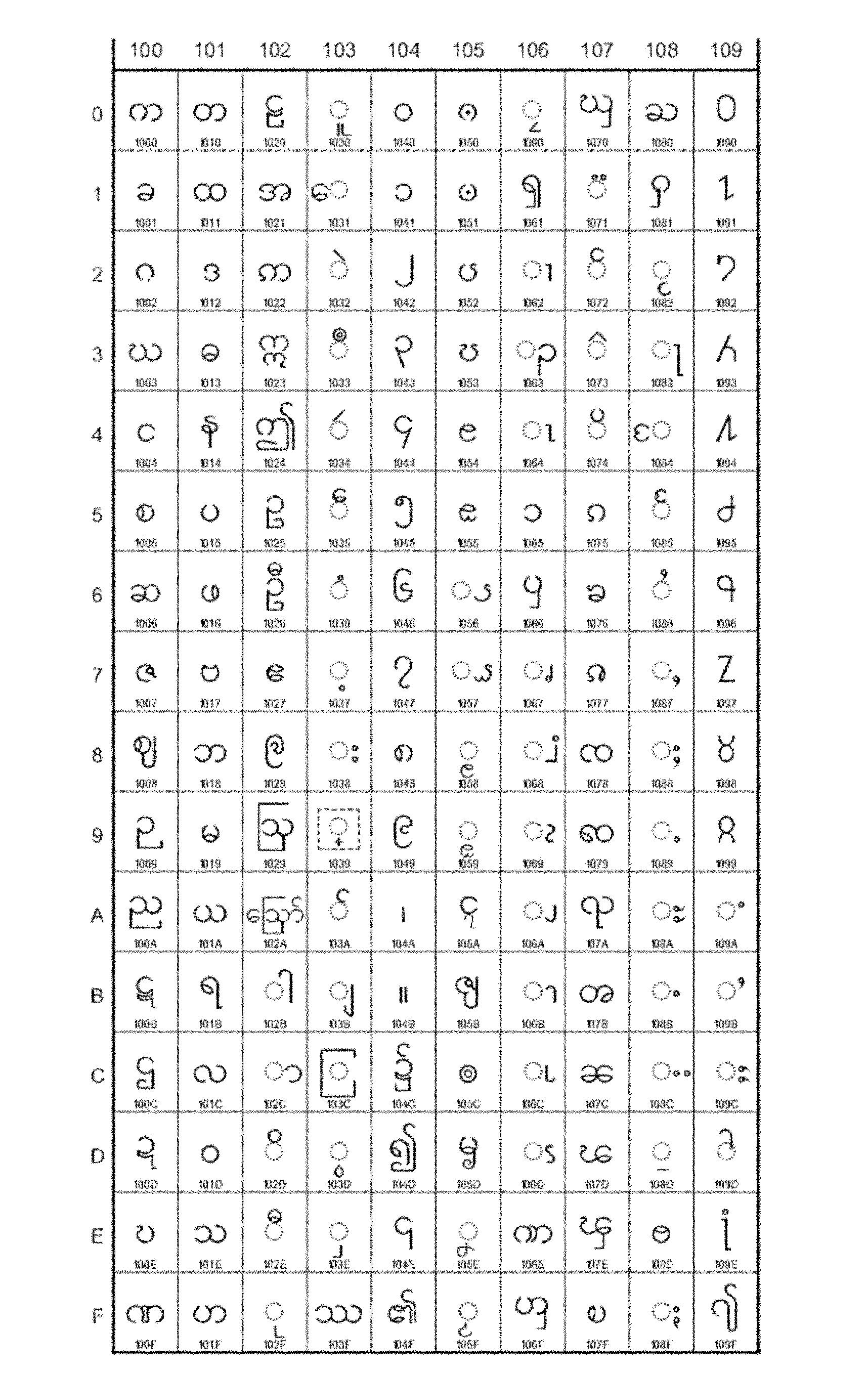

Method for displaying Myanmar by set-top box (STB)

InactiveCN102026033ASave storage resourcesShorten development timeSelective content distributionInput/output processes for data processingProgramming languageDot matrix

The invention provides a method for displaying Myanmar by a set-top box. The method for displaying Myanmar by a set-top box (STB) comprises the following steps of: converting the character strings of a Myanmar word stock into dot matrix data; recording the width / height data of each string into a dot matrix word stock at the same time; registering the string required to be combined with other strings in the Myanmar word stock, and registering the start coordinates and location of the combined string in the dot matrix word stock; when the set-top box displays Myanmar, searching for the requiredstring in the dot matrix word stock according to the character code; taking out the character data of the string to obtain the width height of the string; reading the code of the next string needing to be combined; taking out the required string; and combining the string according to the start coordinates and location of the previous string to finish the display of a complete Myanmar word. Through the method for displaying Myanmar by the STB, the digital television set-top box with Myanmar is realized, thus the hardware storage resources of the set-top box are saved, and the development time of developers is shortened.

Owner:FUJIAN NEWLAND COMM SCI TECH

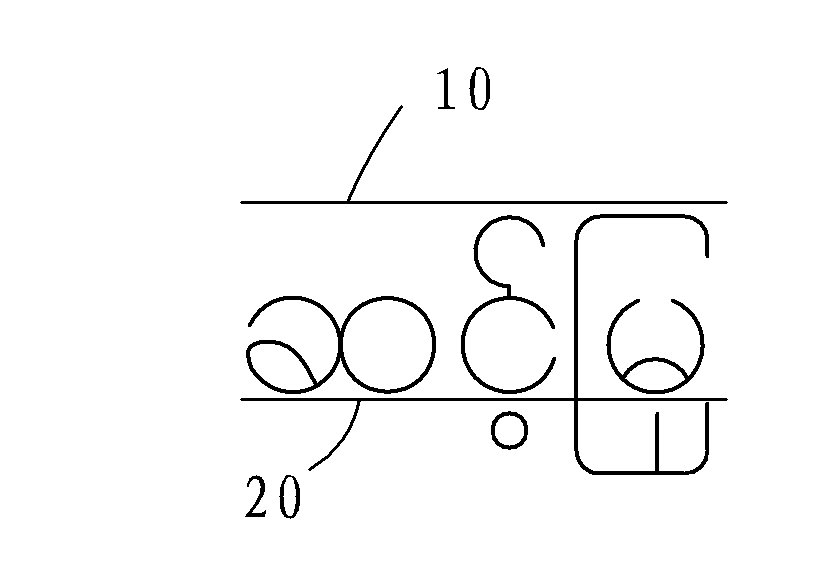

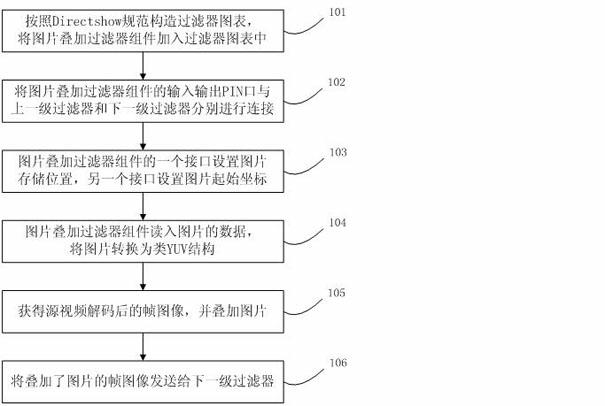

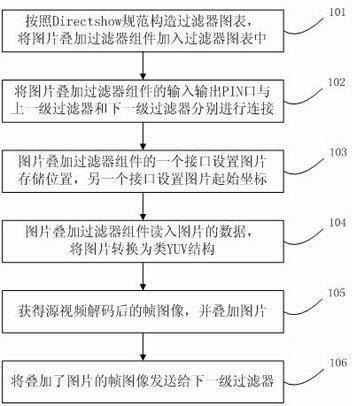

Method for overlaying pictures in video

InactiveCN102685397AShorten the timeGuaranteed to be clear and beautifulTelevision system detailsColor signal processing circuitsGreek letter alphaStart coordinates

The invention discloses a method for overlaying pictures in a video, which comprises the steps: constructing a filter chart according to Directshow standards and adding a picture overlaying filter assembly into the filter chart; connecting input and output PIN ports of the picture overlaying filter assembly; setting a storage position of the pictures at one interface of the picture overlaying filter assembly and setting starting coordinates of a placing position of the pictures at another interface, and adding an ALPHA channel value into the pictures; reading data of pictures by the picture overlaying filter assembly and converting the data into a YUV structure; obtaining frame images of the decoded source video and overlaying the pictures; and sending the frame images overlaid with the pictures to a filter of next level. With the adoption of the technical scheme, the pictures in the video are enabled to be displayed more clearly and beautifully, convenience is provided for subsequent operation, and the time spent in overlaying the pictures is saved.

Owner:TVMINING BEIJING MEDIA TECH

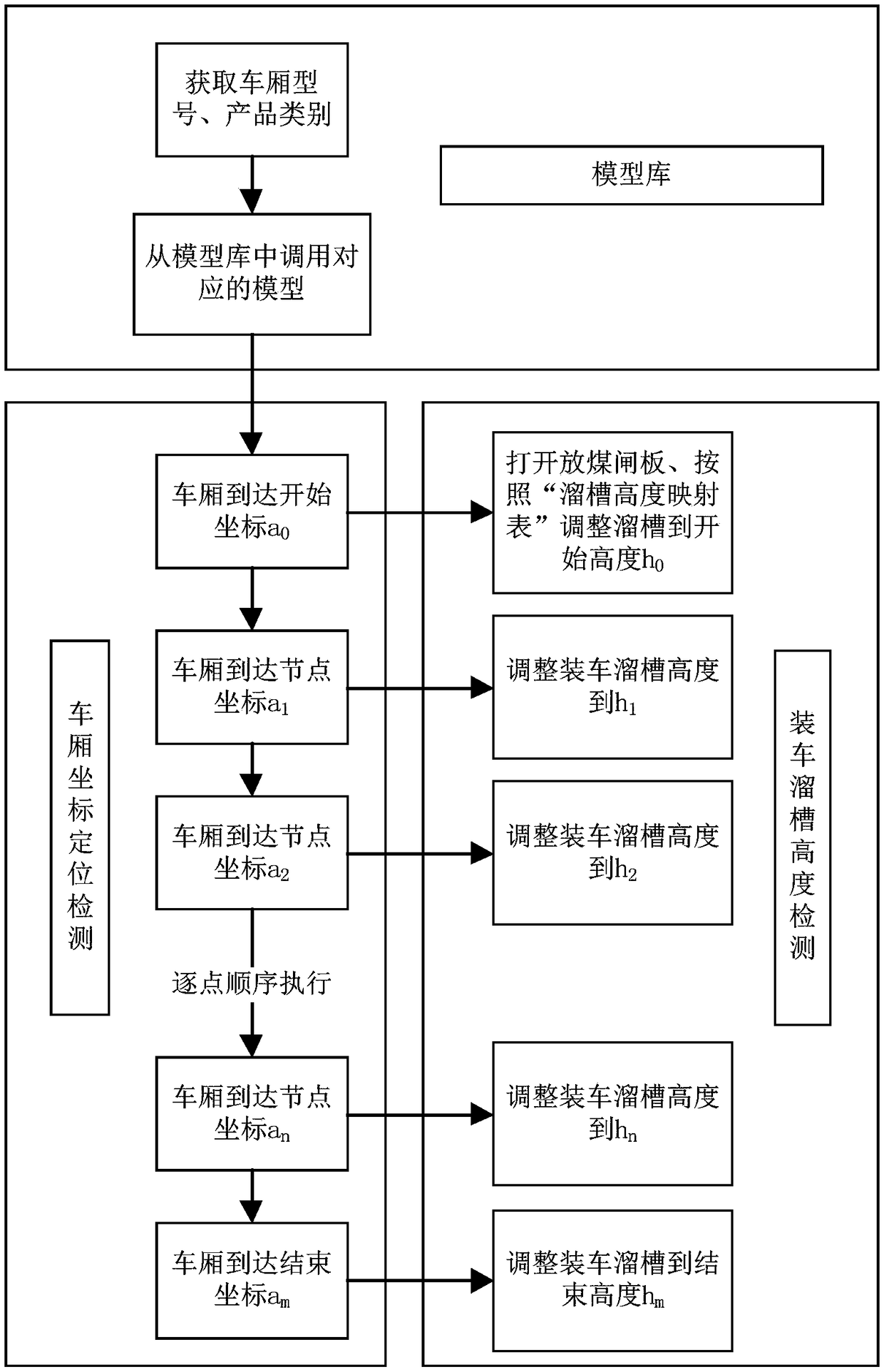

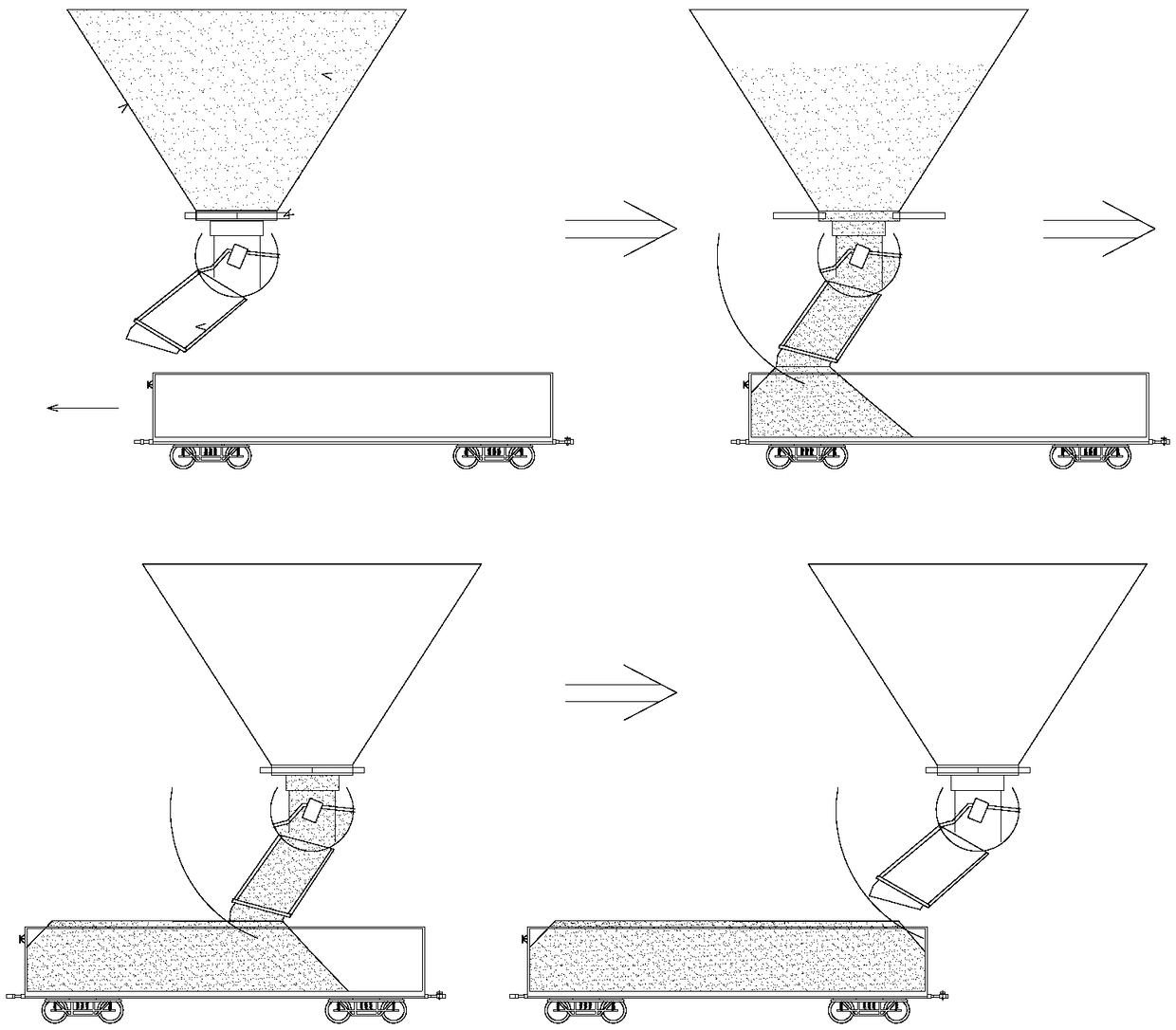

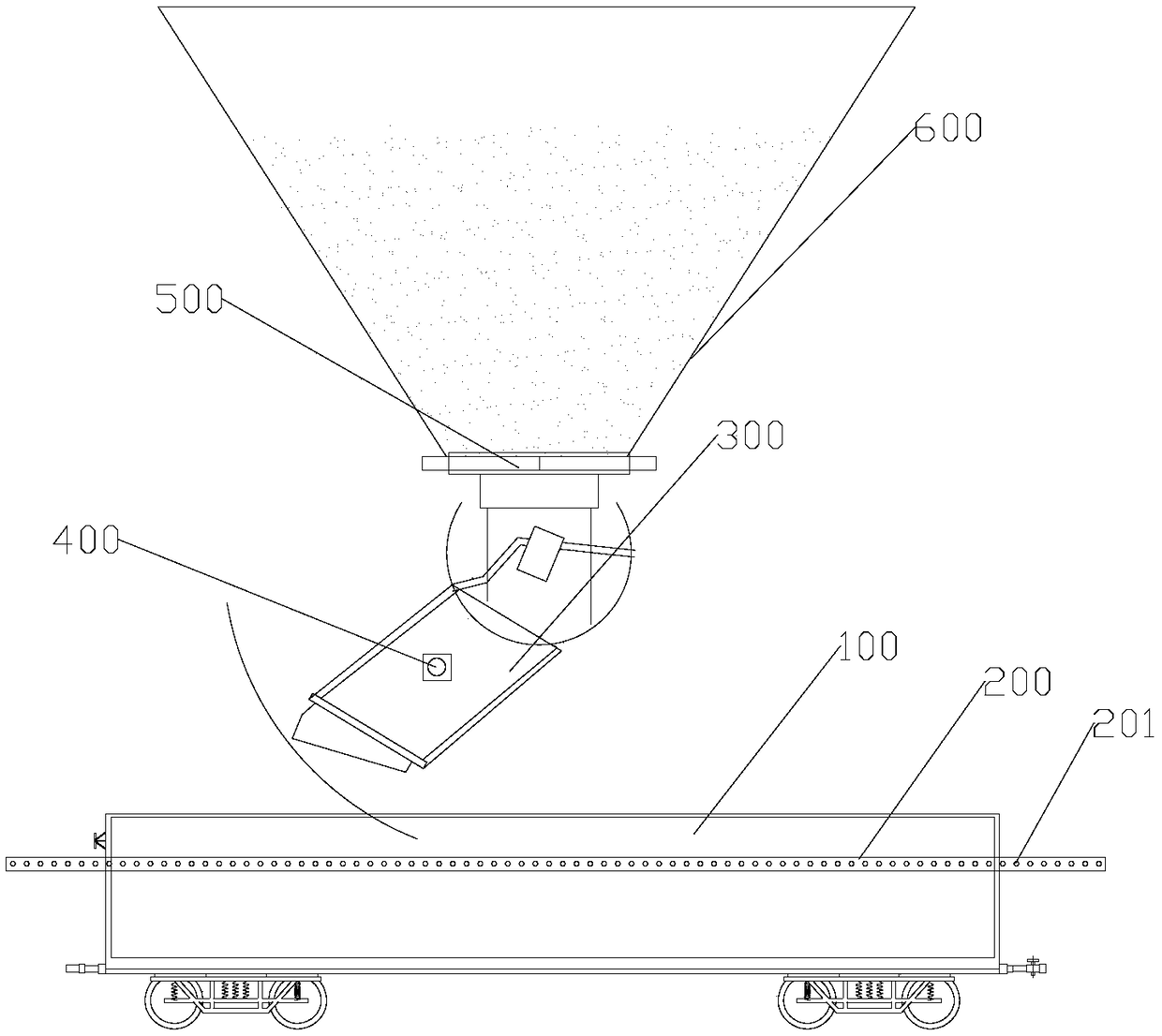

Intelligent truck loading method and device

PendingCN109292483AReduce labor intensityImprove accuracyConveyorsControl devices for conveyorsProduct typeProcess engineering

The invention provides an intelligent truck loading method and device, and relates to the technical field of truck loading systems for bulk materials such as coal. The method comprises the following steps that 1, a corresponding model is acquired from a model base according to the truck bed type and the product type; 2, after a truck bed enters a coordinate detection area, the coordinate value ofthe truck bed starts to be recorded; 3, when the truck bed drives to the start coordinate a0, a coal discharge gate plate is automatically opened, the corresponding height from a truck loading chuck to the start coordinate h0 is adjusted according to the model, and materials gradually flow from a bin into the truck bed; 4, according to the truck bed driving coordinate an, the truck loading chute is adjusted to the corresponding height of the coordinate hn; 5, when the truck bed drives to the finish coordinate am, the truck loading chute is adjusted to be corresponding height hm, and loading ofthe truck bed is finished; and 6, the steps 2-5 are repeated till loading of all truck beds is finished. By means of the intelligent truck loading method and device, the unmanned truck loading process is achieved, truck loading accuracy is improved, and the problem that manual truck loading quality is unstable is solved.

Owner:TIANJIN MEITENG TECH CO LTD

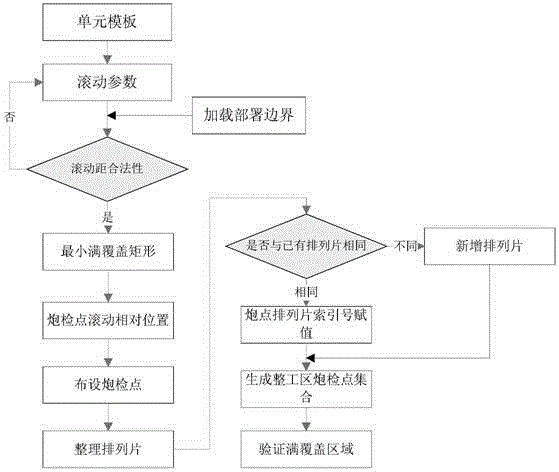

Concave polygon region observation system automatic full coverage quick layout method

ActiveCN105319576ARealize automatic artillery inspection point layoutIncrease deployment speedSeismic signal receiversArray data structureObservation system

The invention provides a concave polygon region observation system automatic full coverage quick layout method, which belongs to the field of seismic exploration and development. The method comprises the steps that (1) a unit template is established, wherein the unit template comprises the parameters of the number of detection lines, the number of detection points, track pitch, detection line pitch, detection point starting coordinates, the number of shot lines, the number of shot points, shot point pitch, shot line pitch and shot point starting coordinates; (2) rolling parameters and a concave polygon deployment boundary are established, wherein the rolling parameters comprises rolling azimuth, inline direction rolling pitch, x-line direction rolling pitch, and the deployment boundary is composed of a one-dimensional array and comprises all inflection point coordinates of the boundary, namely (x, y); and (3) a minimum full coverage region rectangle is calculated. According to the step (3), the minimum number of times of rolling in inline direction and the minimum number of times of rolling in x-line direction are calculated through the parameters of the unit template and the rolling parameters, wherein the minimum numbers of times are needed by unit template rolling layout to reach full coverage.

Owner:CHINA PETROLEUM & CHEM CORP +1

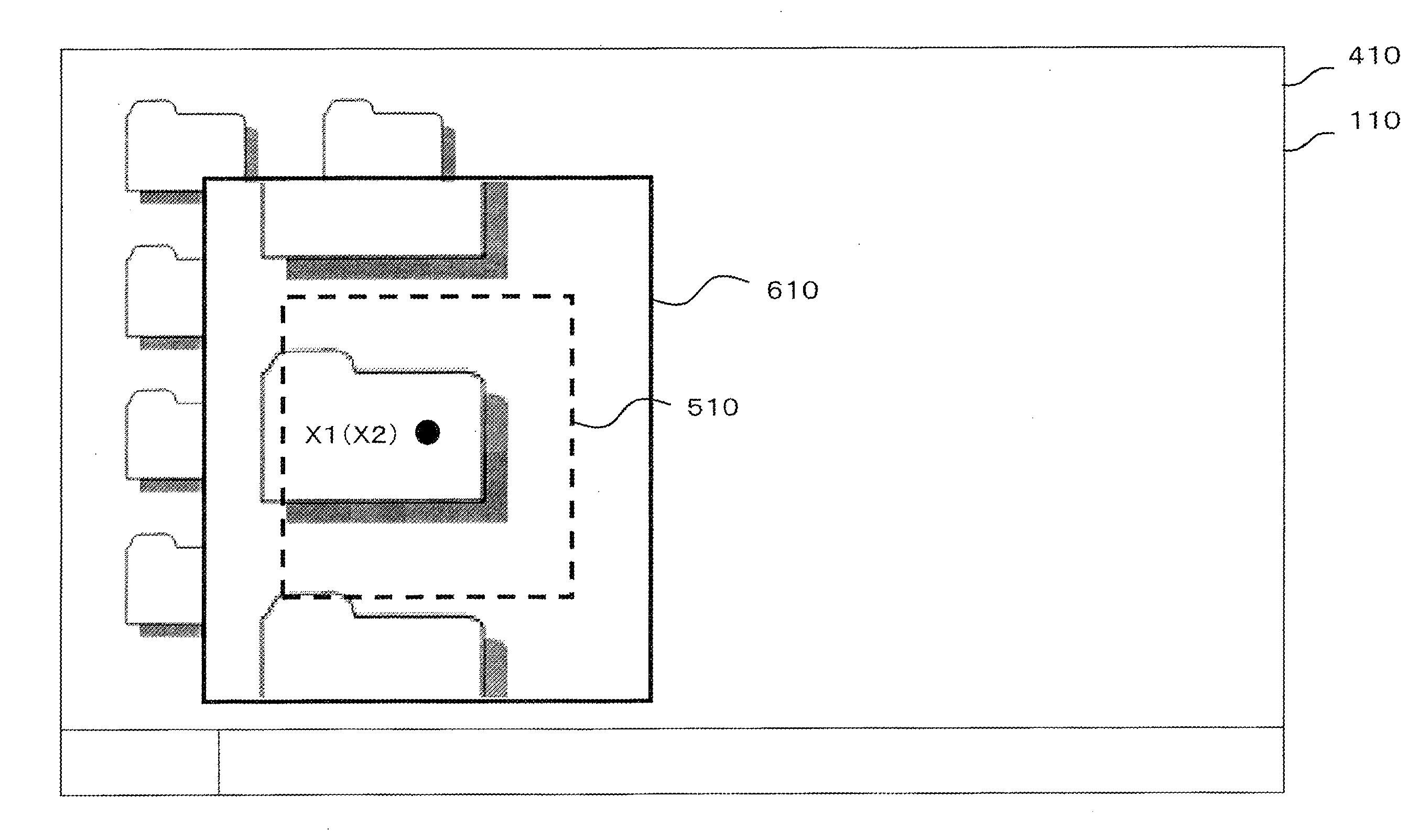

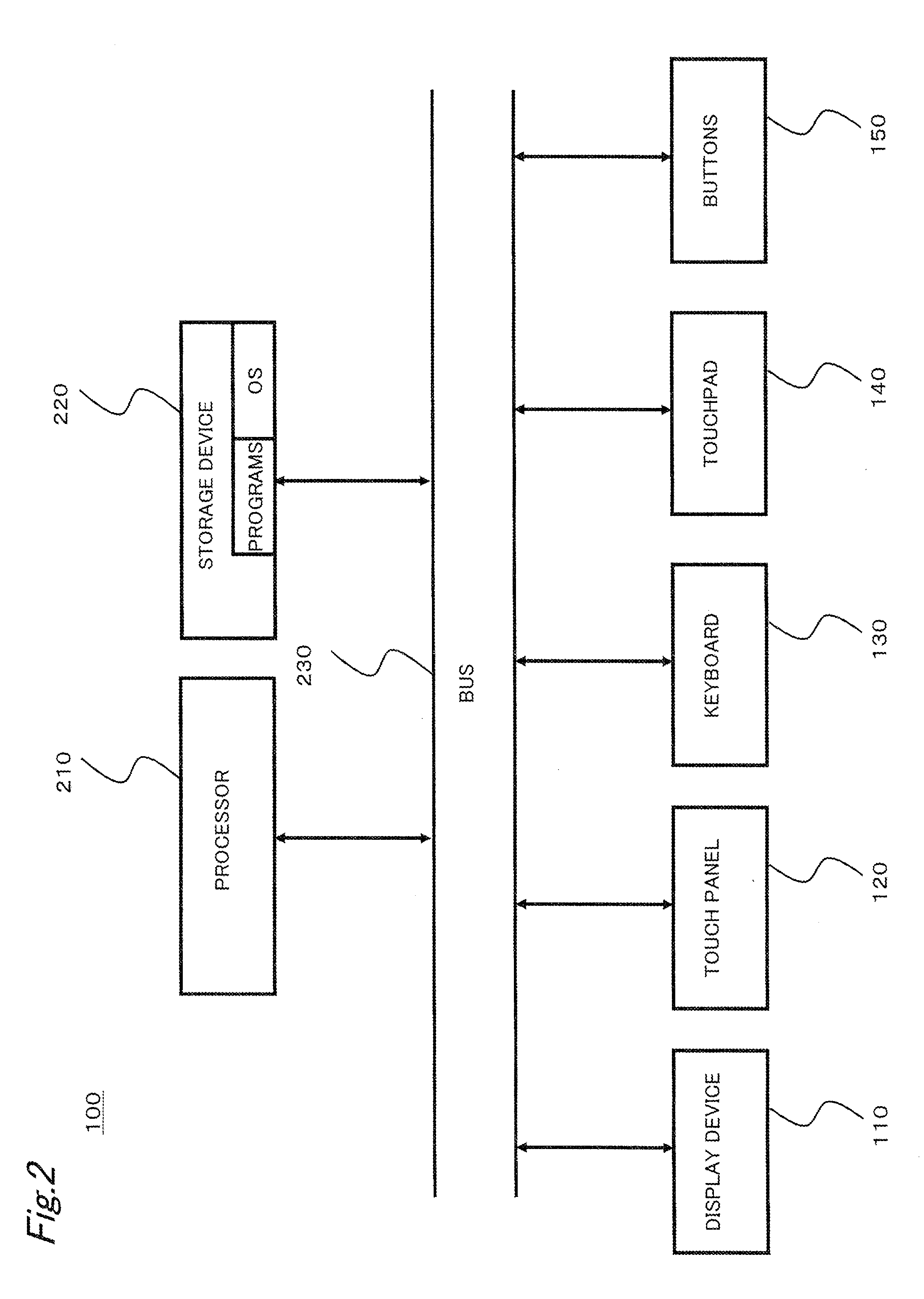

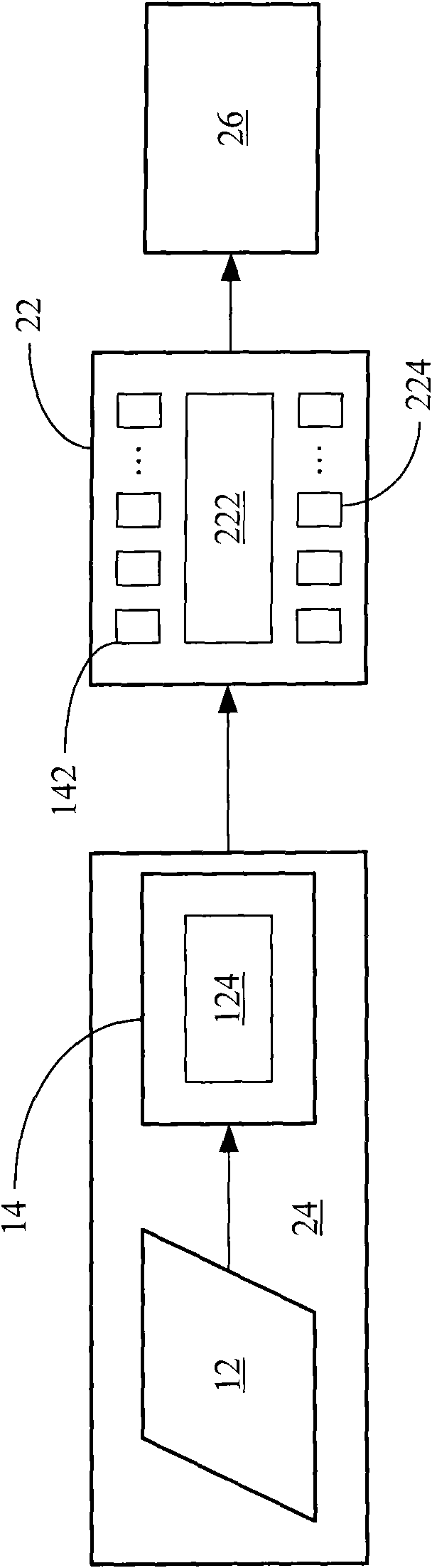

Information processing apparatus

ActiveUS20140380188A1Easy to operateInput/output processes for data processingInformation processingInformation handling

A processor of an information processing apparatus sets an enlargement target region in a system screen based on coordinates inputted in a coordinate input unit, superimposes and displays an enlarged image obtained by enlarging the enlargement target region, on the system screen, monitors whether or not the input in the coordinate input unit in the state where the enlarged image is displayed is performed through a drag operation of which starting coordinates are in the enlarged image. When the input in the coordinate input unit in the state where the enlarged image is displayed is performed through a drag operation of which starting coordinates are within the enlarged image, the processor monitors coordinates while the drag operation is performed. When the coordinates while the drag operation is performed come to be present within a predetermined range defined by the edge of the enlarged image, the processor erases the enlarged image.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method of applying peer-to-peer network platform based on hub-node

InactiveCN1567196AReduce operating costsGrowth law highMultiple digital computer combinationsProgram loading/initiatingExtensibilityThe Internet

This invention relates to computer and Internet. By starting coordinate network platform, coordinate network platform core service module, coordinate network platform application in turn, it creates (1) credit service; (2) file storing service; (3) file copying service; (4) security service; (5) router service. This invention takes full advantage of idle and free system resource of terminal user, such as network bandwidth, hardware storing space, idle CPU cycle, so as to reduce the enterprise operation cost remarkably, at the same time provides availability and expandability furthest.

Owner:程浩 +1

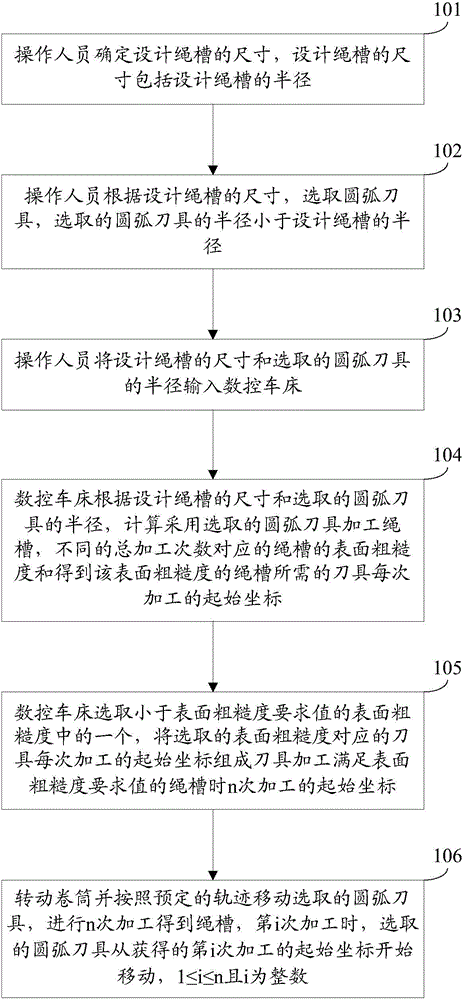

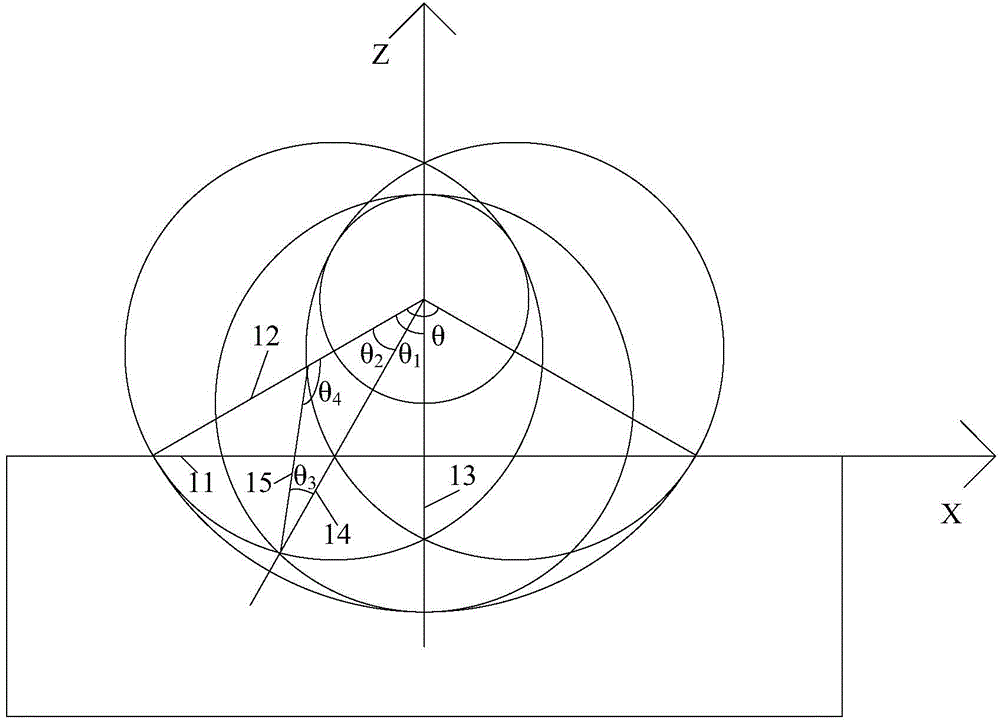

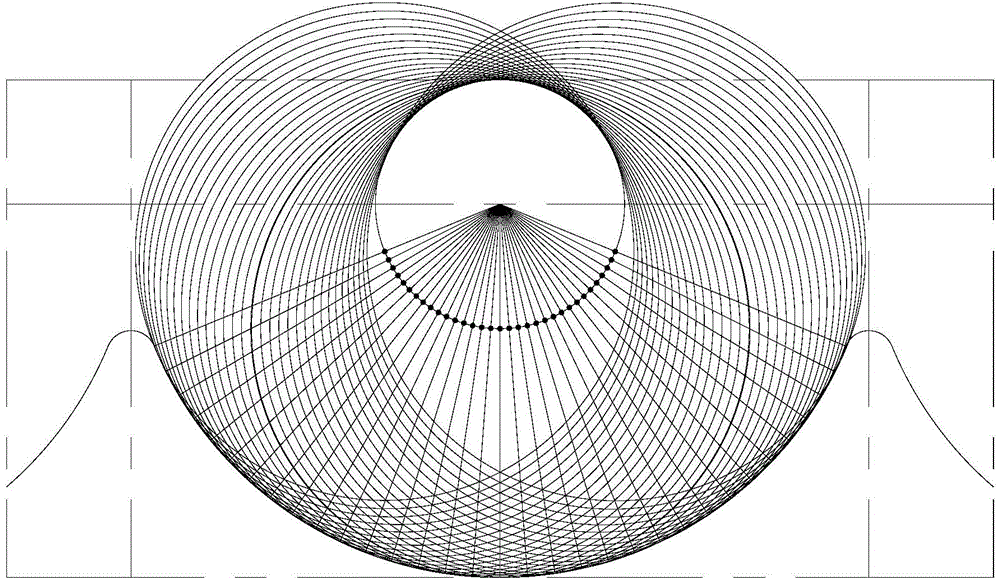

Method for processing coiling block rope race

The invention discloses a method for processing a coiling block rope race and belongs to the field of machinery. The method includes acquiring the size of the designed rope race and the radius of a selected arc cutter, wherein the size of the designed rope race includes the radius and the depth of the designed rope race and an angle formed by arch surfaces between a starting point and an end point of a cross surface of the designed rope race, and the radius of the selected arc cutter is smaller than that of the designed rope race; acquiring starting coordinates of n-time processes when the selected arc cutter processes the rope race which meets surface roughness requirements, wherein n>=2, and n is an integer; rotating a coiling block, moving the selected arc cutter according to a predetermined track, and performing n-time processing to obtain the rope race, wherein the i processing is performed, the selected arc cutter begins to move from the obtained starting coordinate of the i processing, 1<=i<=n, and i is an integer. According to the method for the method for processing the coiling block rope race, conditions of messing and clamping of ropes can be avoided, and processing efficiency is high.

Owner:WUHAN MARINE MACHINERY PLANT

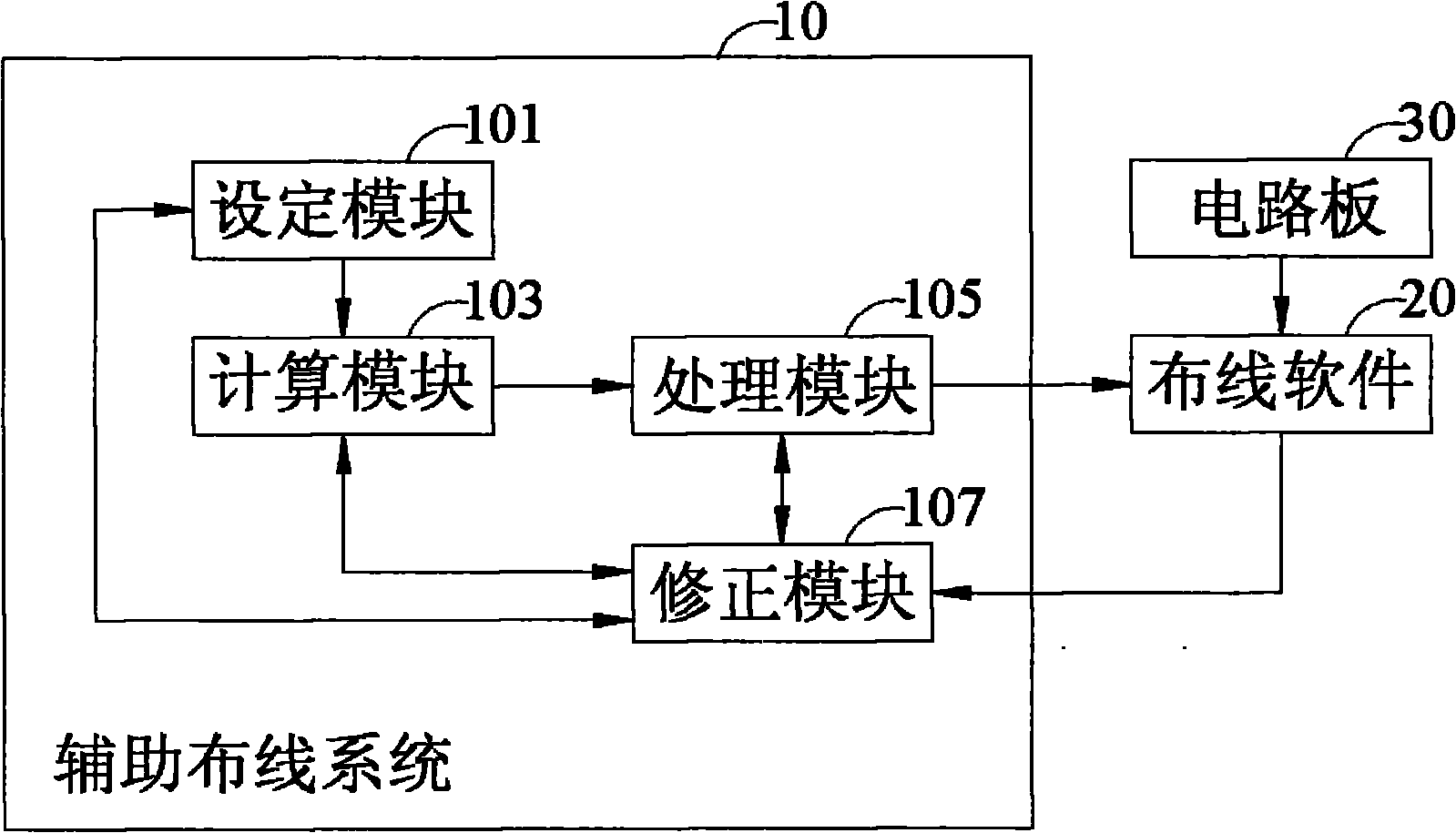

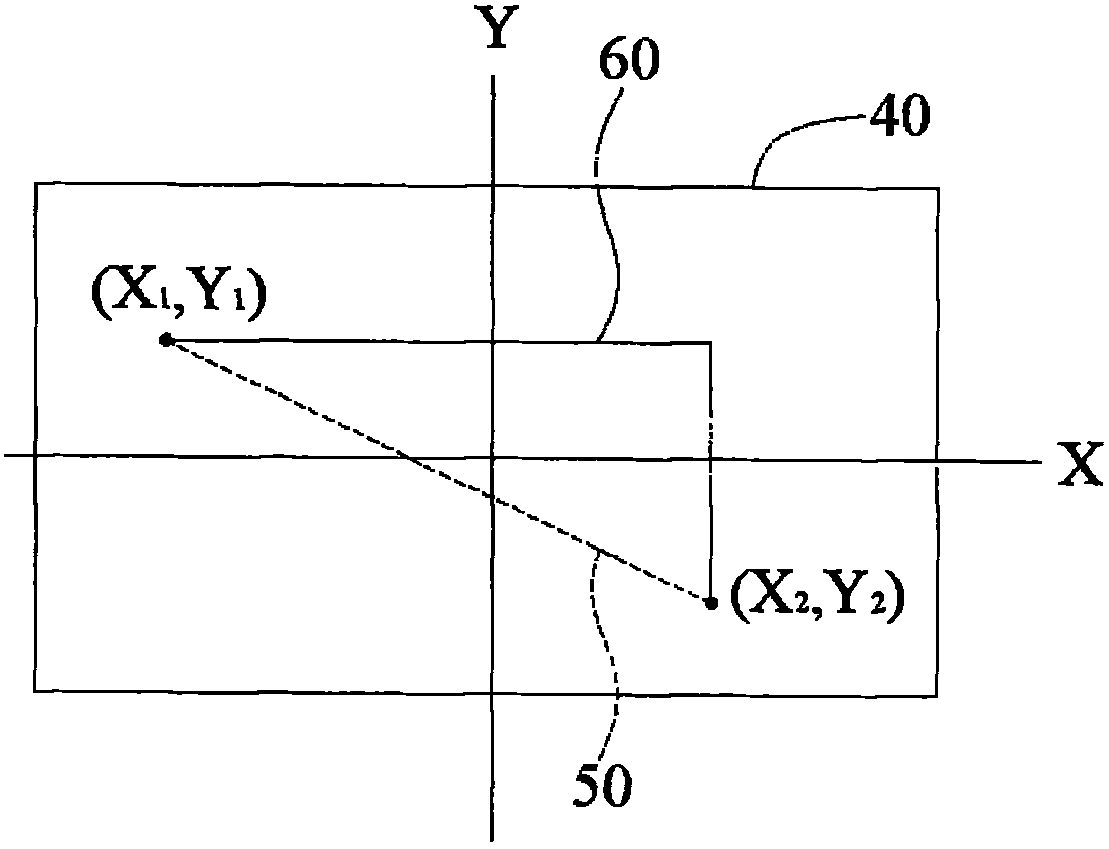

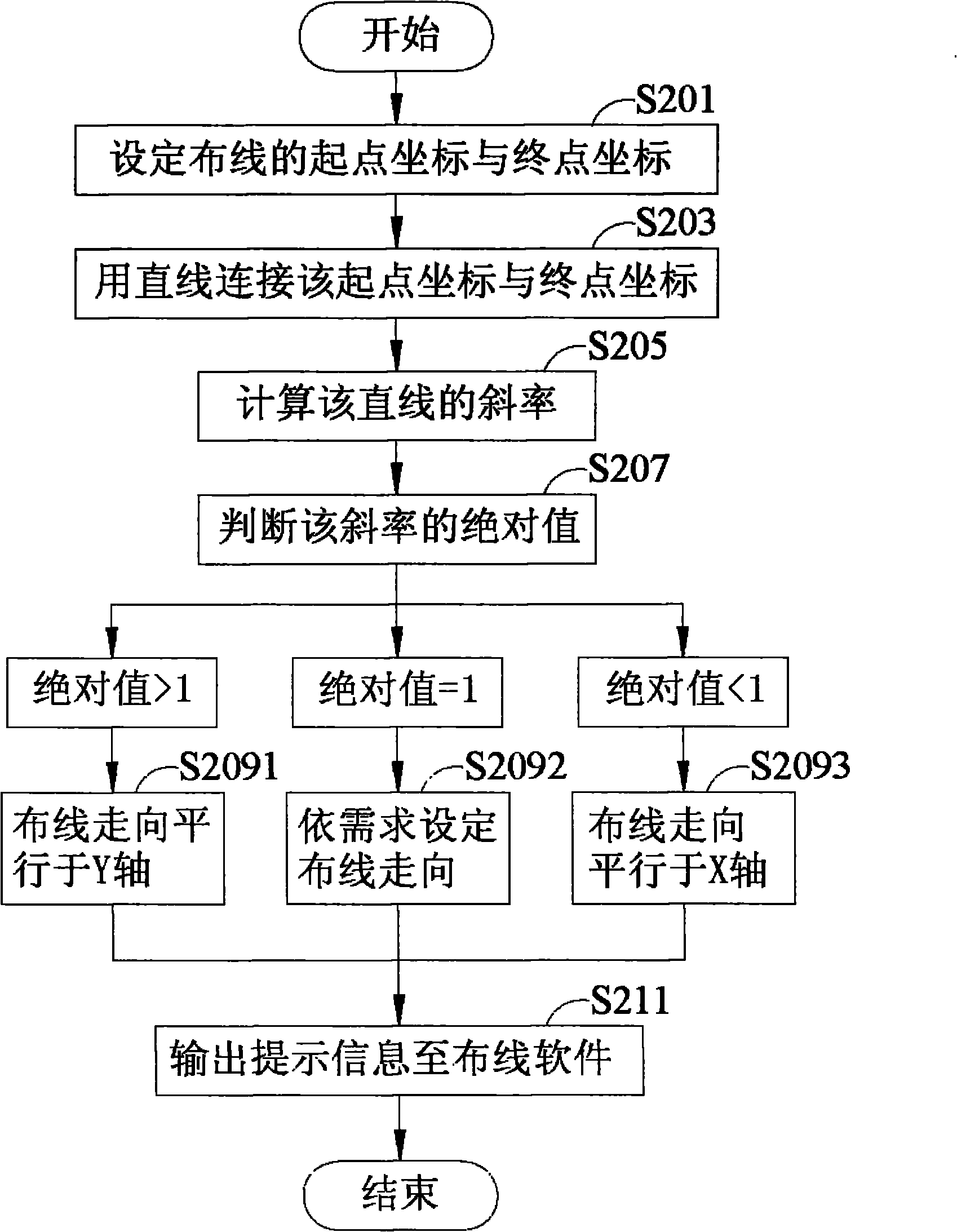

Assistant wiring system and method

InactiveCN101944137AImprove qualityImprove efficiencySpecial data processing applicationsEngineeringHorizontal and vertical

The invention relates to assistant wiring system and method for assisting wiring software to wire a circuit board, mainly comprising the following steps of: calculating the slope of a straight line by connecting the starting coordinate position and the stopping coordinate position of a signal wire to be arranged through the straight line and referring to the positions of an X axis and a Y axis of a wiring interface; and deciding a wiring way of the signal wire according to a calculating result so as to assist the wiring software to carry out wiring operation on the circuit board in an optimal horizontal and vertical wiring way, therefore the wiring quality and the wiring efficiency of the circuit board are enhanced.

Owner:INVENTEC CORP

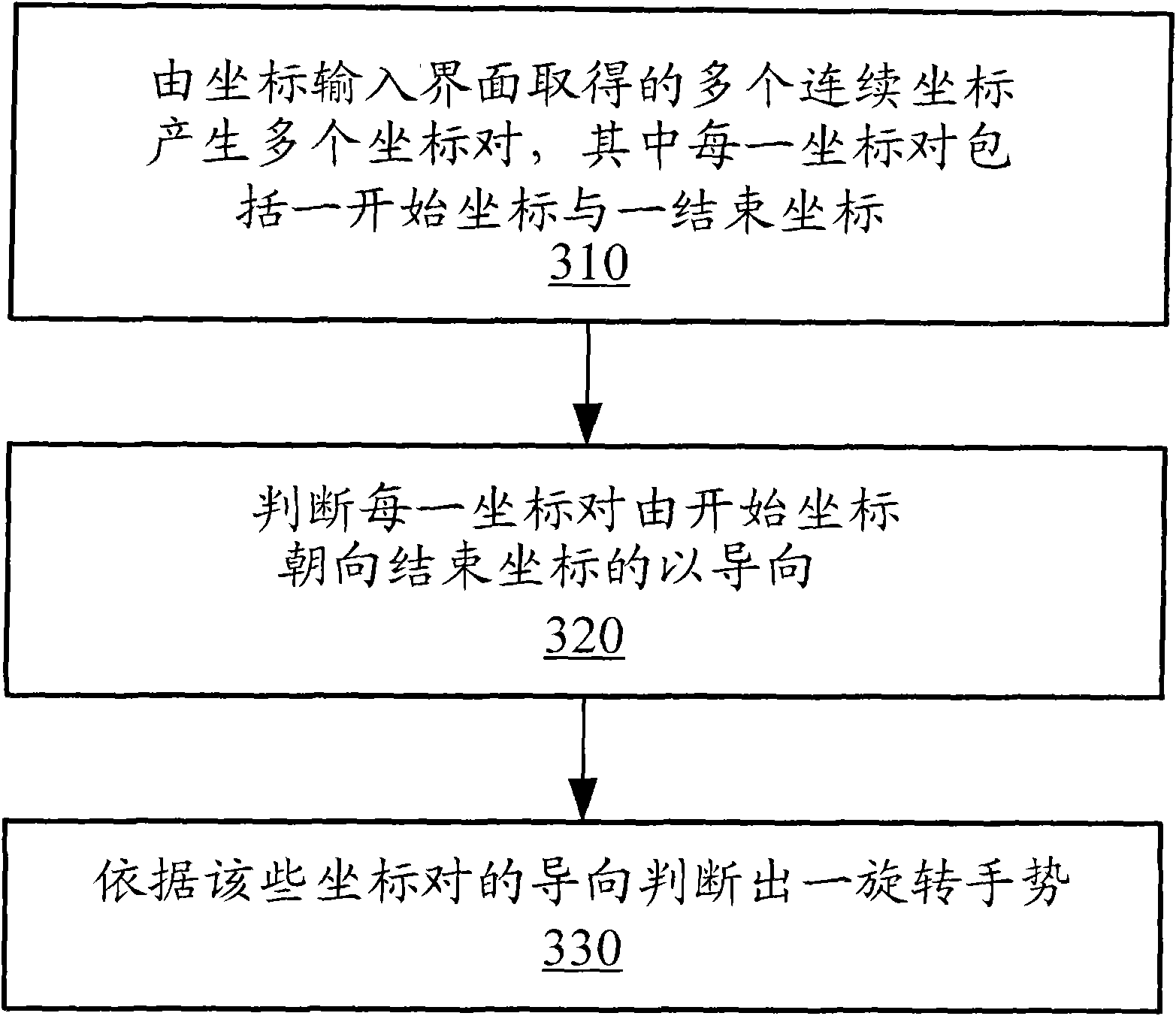

Method and device for identifying rotation gesture

ActiveCN102169379AMisjudgment of public avoidance as a flaw in the rotation gestureJudging the touch trajectoryInput/output processes for data processingHuman–computer interactionClockwise

The invention discloses a method and a device for identifying a rotation gesture. The method for identifying the rotation gesture comprises the following steps of: generating a plurality of coordinate pairs by a plurality of continuous coordinates which are obtained by a coordinate input interface, wherein each coordinate pair comprises a start coordinate and an end coordinate; judging the orientation of each coordinate pair from the start coordinate to the end coordinate; and judging the rotation gesture according to the orientation of the coordinate pairs. The device for identifying the rotation gesture comprises a memory, the coordinate input interface and a programmable processing unit, wherein the memory memorizes a rotation gesture judgement program and a plurality of reference orientation ranges which are determined according to clockwise direction or anticlockwise direction; the coordinate input interface comprises a touch device and a controller; and the programmable processing unit identifies the rotation gesture according to the rotation gesture judgement program.

Owner:EGALAX EMPIA TECH INC

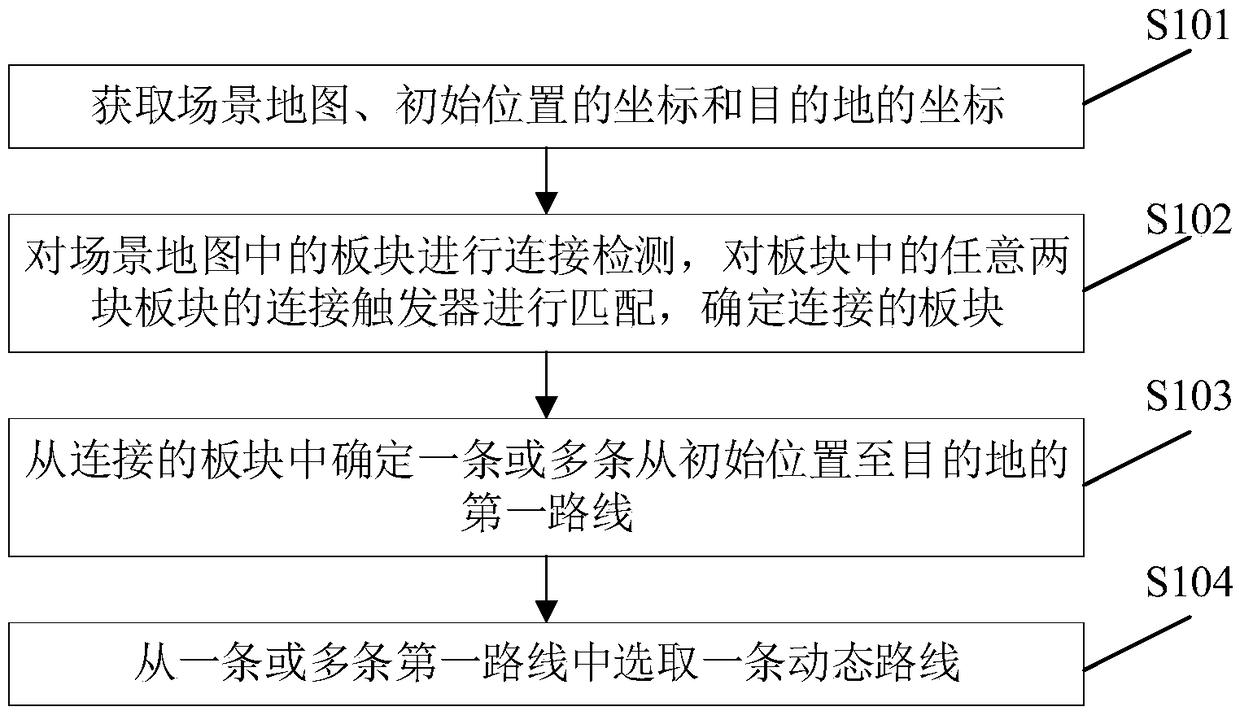

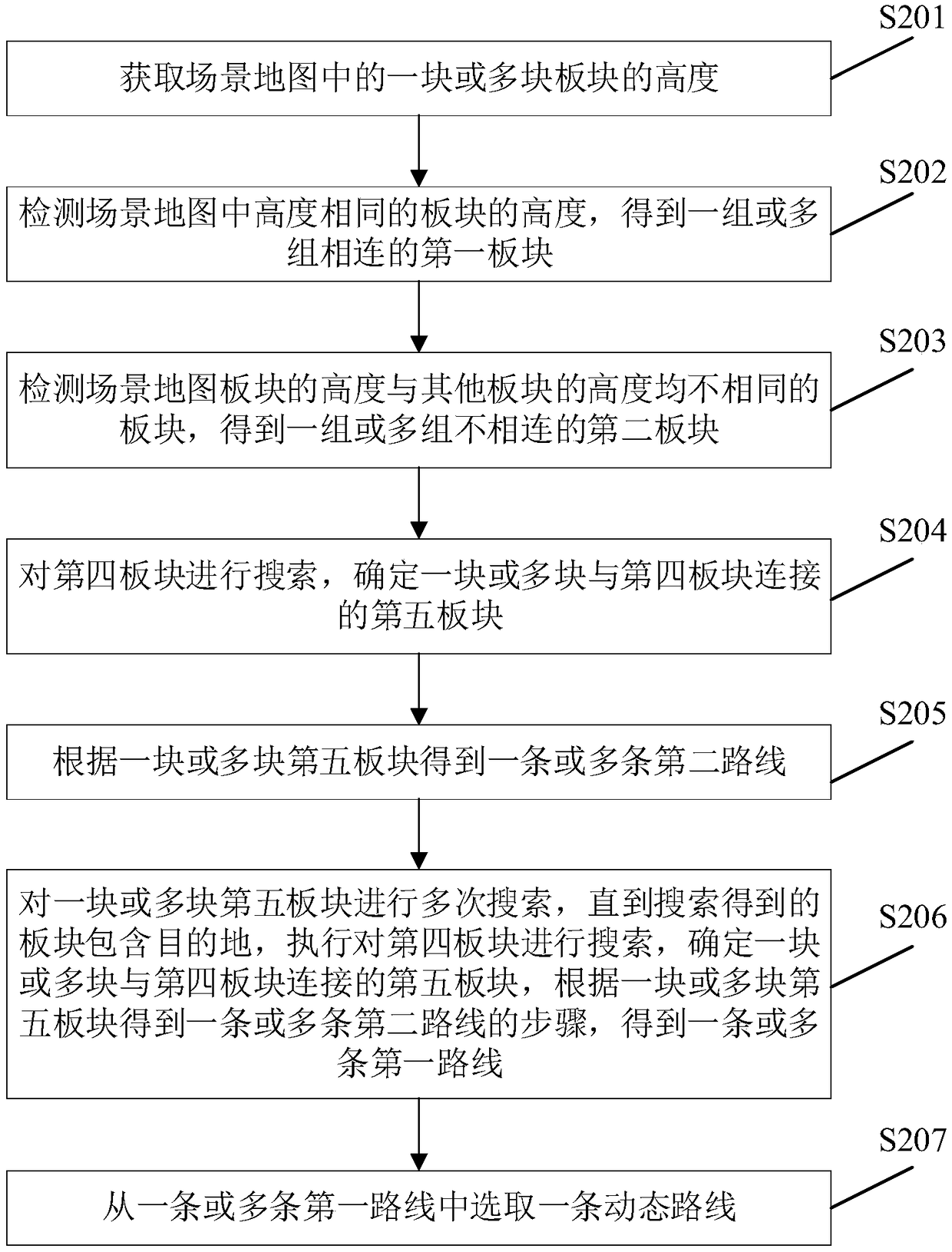

Method and apparatus for generating dynamic route

A method and apparatus for generating a dynamic route are disclosed. The method includes obtaining a scene map, a coordinate of an initial position and a coordinate of a destination, wherein the scenemap comprises one or more plates of the same size; carrying out connection detection on the plates in the scene map, matching the connection triggers of any two plates in the plates, and determiningthe connected plates; determining one or more first paths from the starting coordinates to the target coordinates from the connected plates; and selecting a dynamic route from the one or more first routes, wherein the dynamic route is the first route with the shortest path. A corresponding device is also disclosed. By judging the matching of the connection trigger to complete the judgment of the connection of any two blocks in the scene map, and then according to the connection of all blocks in the scene map, real-time and accurate generation of dynamic route.

Owner:SHENZHEN IDREAMSKY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com