A Drilling Method of CNC Milling Machine with Tilting Spindle

A technology of CNC milling machine and processing method, applied in the field of mechanical processing, can solve the problem of lack of drilling processing method of CNC milling machine with tiltable spindle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe the present invention below in conjunction with specific embodiment:

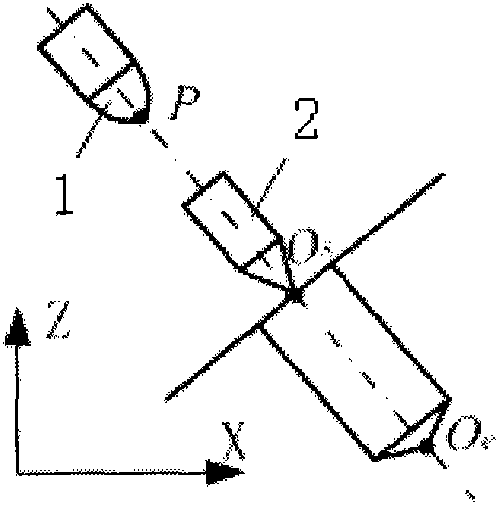

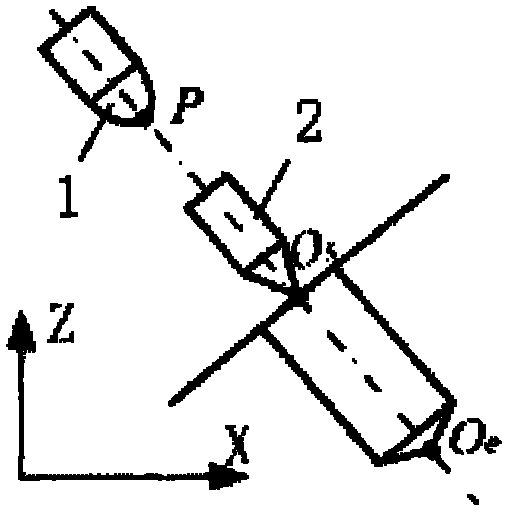

[0019] This embodiment is for drilling the aero-engine casing. Because the blades of the blisk are fixed in the casing, which causes occlusion, ordinary CNC machine tools cannot be processed, and the processing cost is limited, so the five-coordinate machining center cannot be used. CNC milling machine with tiltable spindle for drilling.

[0020] Step 1: Clamp the casing on the machine tool; tilt the machine tool spindle around the Y direction of the machine tool coordinate system, and use a sine gauge to verify the tilt angle, so that the machine tool spindle is perpendicular to the surface of the casing to be drilled; after determining the tilt angle of the machine tool spindle , clamp a standard tool on the machine tool spindle, move the tool so that the central axis of the machine tool spindle coincides with the central axis of the hole to be processed, and measure the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com