Vertical lifting hovercar

A flying car, vertical lift technology, applied in the field of flying cars, can solve the problems of fuel consumption, life, safety, user inconvenience, etc., and achieve the effect of saving horizontal tail, improving safety and flight stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

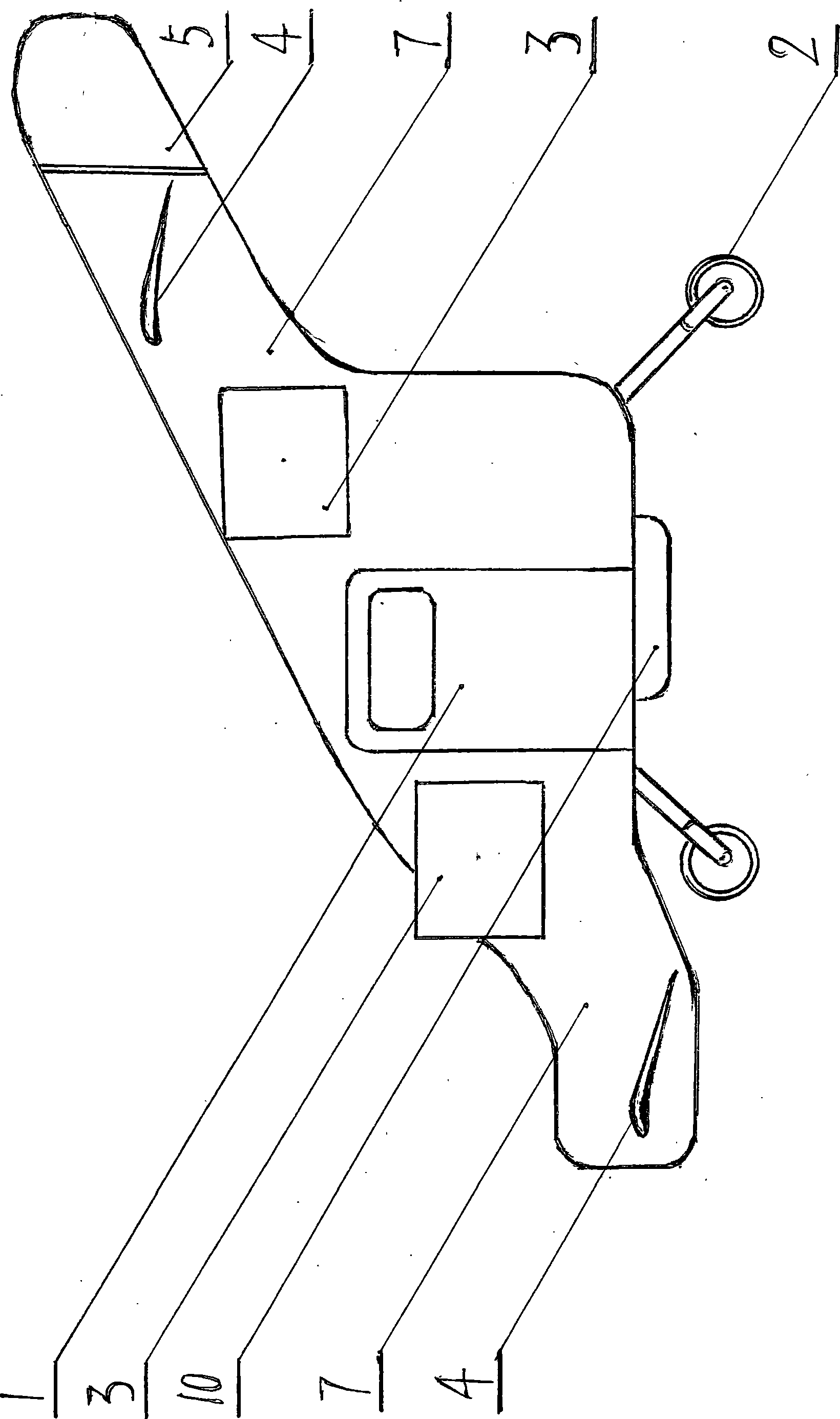

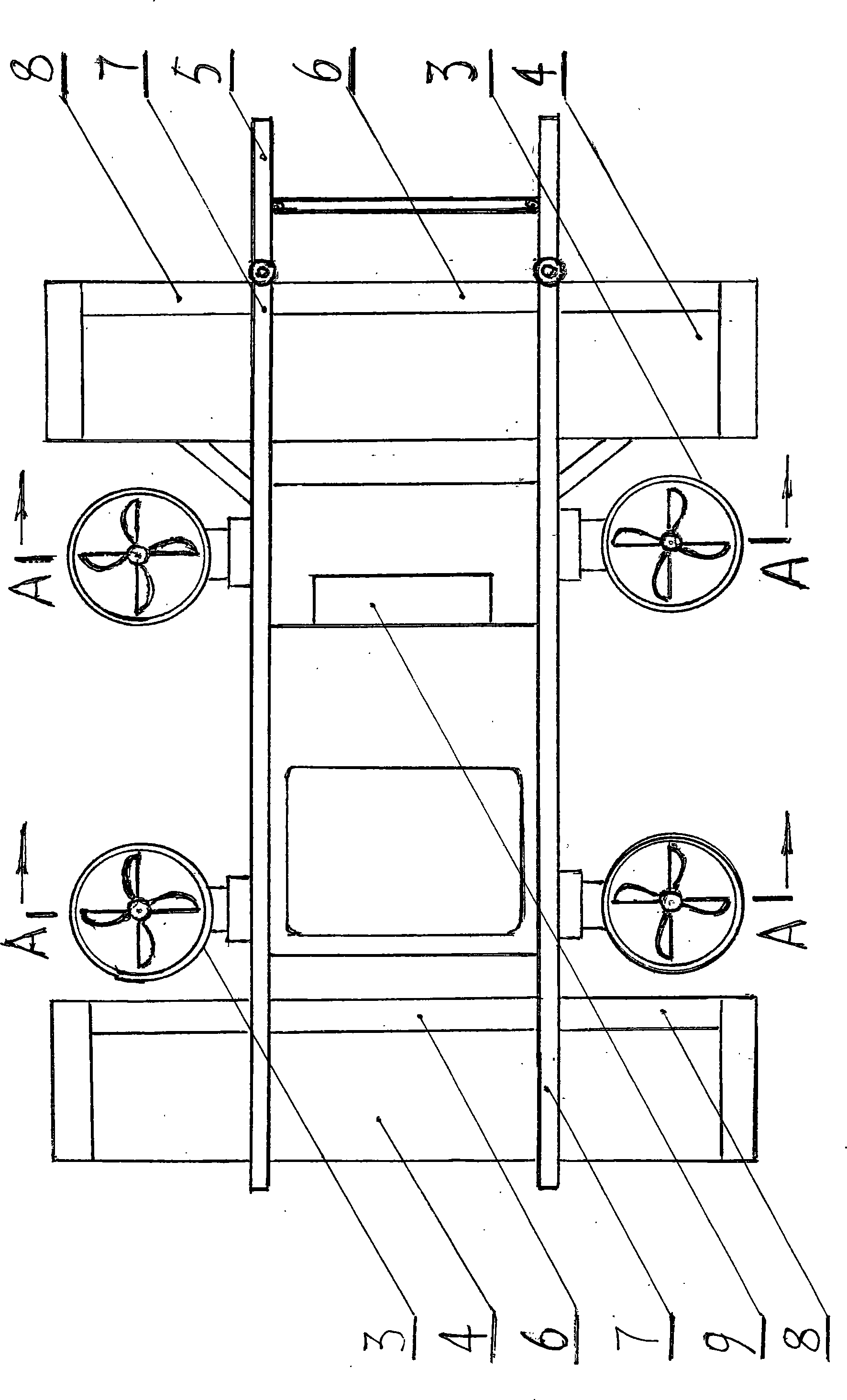

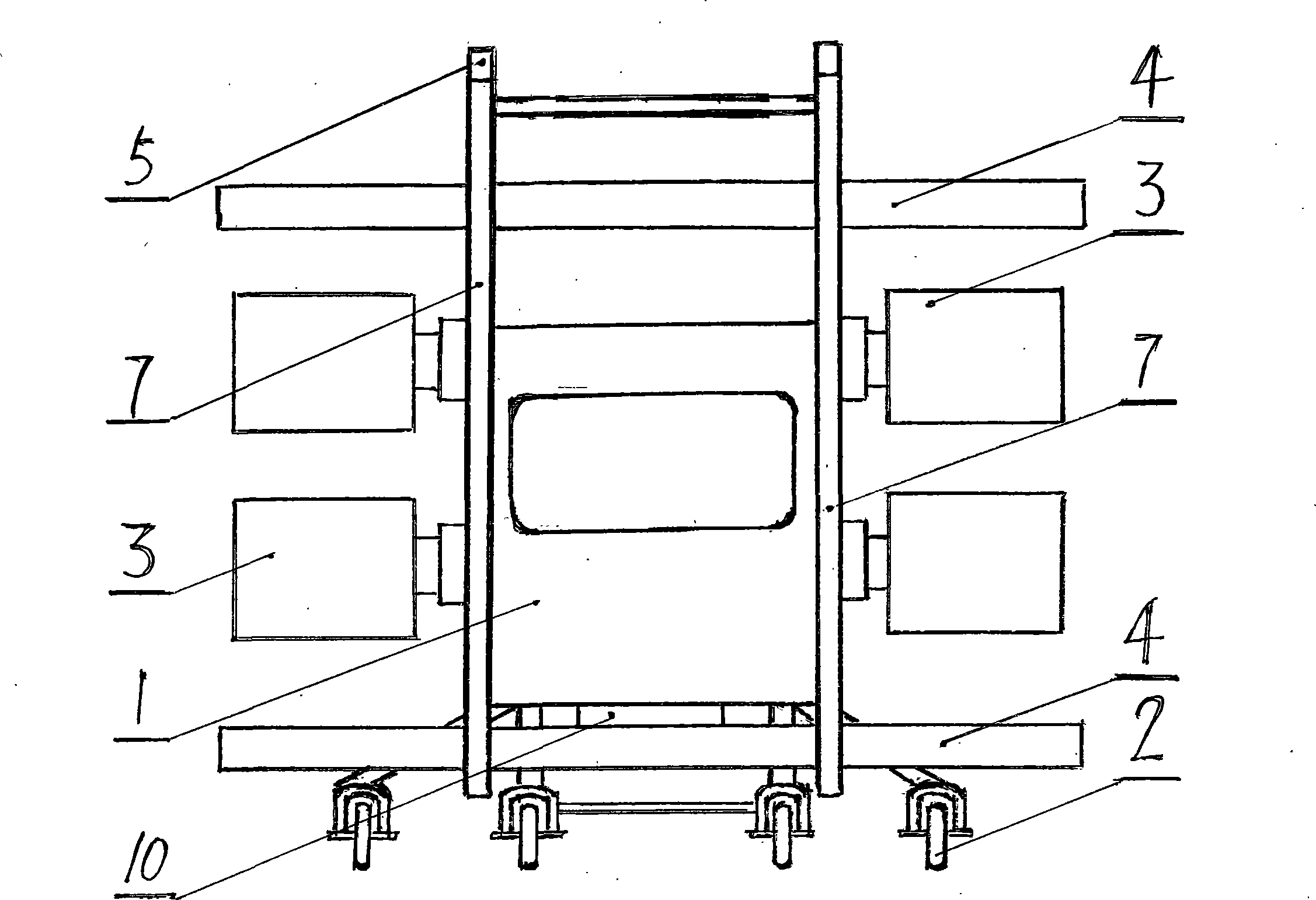

[0014] The flying car of the present invention is equipped with two front and rear engine assemblies, which provide power for the front and rear two pairs of ducted fans respectively. For the power transmission process, see Figure 4 . The power of the engine assembly 11 is transmitted to the ducted fan blade 15 through the transmission shaft 12 and the bevel gear set 13 to provide power for the flying car to drive on the road or fly in the air. Since the left and right ducted fan bevel gear sets 13 The installation direction is opposite, and the rotation direction of the fan blades is also opposite, which can make the rotation torque generated by each pair cancel each other out and keep the overall balance of the flying car. The inlet and outlet of two pairs of ducted fans 3 can be tilted within 180 degrees from horizontal to vertical and then to horizontal. For the tilting operation process, refer to Figure 5 (combined Figure 4 ), the operating rod 18 is pushed forward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com