Winding device and fuelling vehicle

A technology of reel and refueling pipe, which is applied in the field of pipe retraction and cable, can solve the problems of low efficiency, achieve the effect of improving retraction efficiency, improving work efficiency, and reducing the process of back and forth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

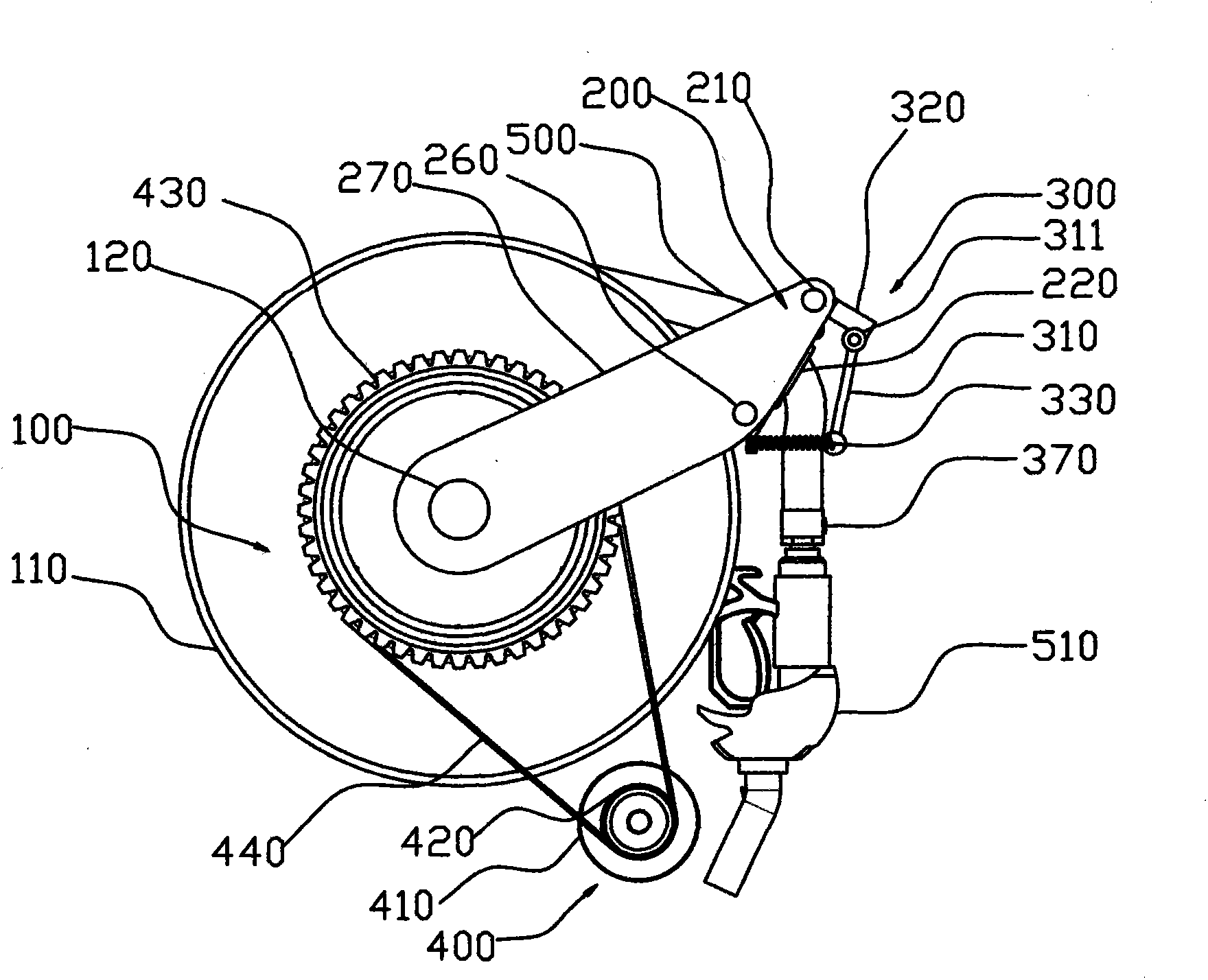

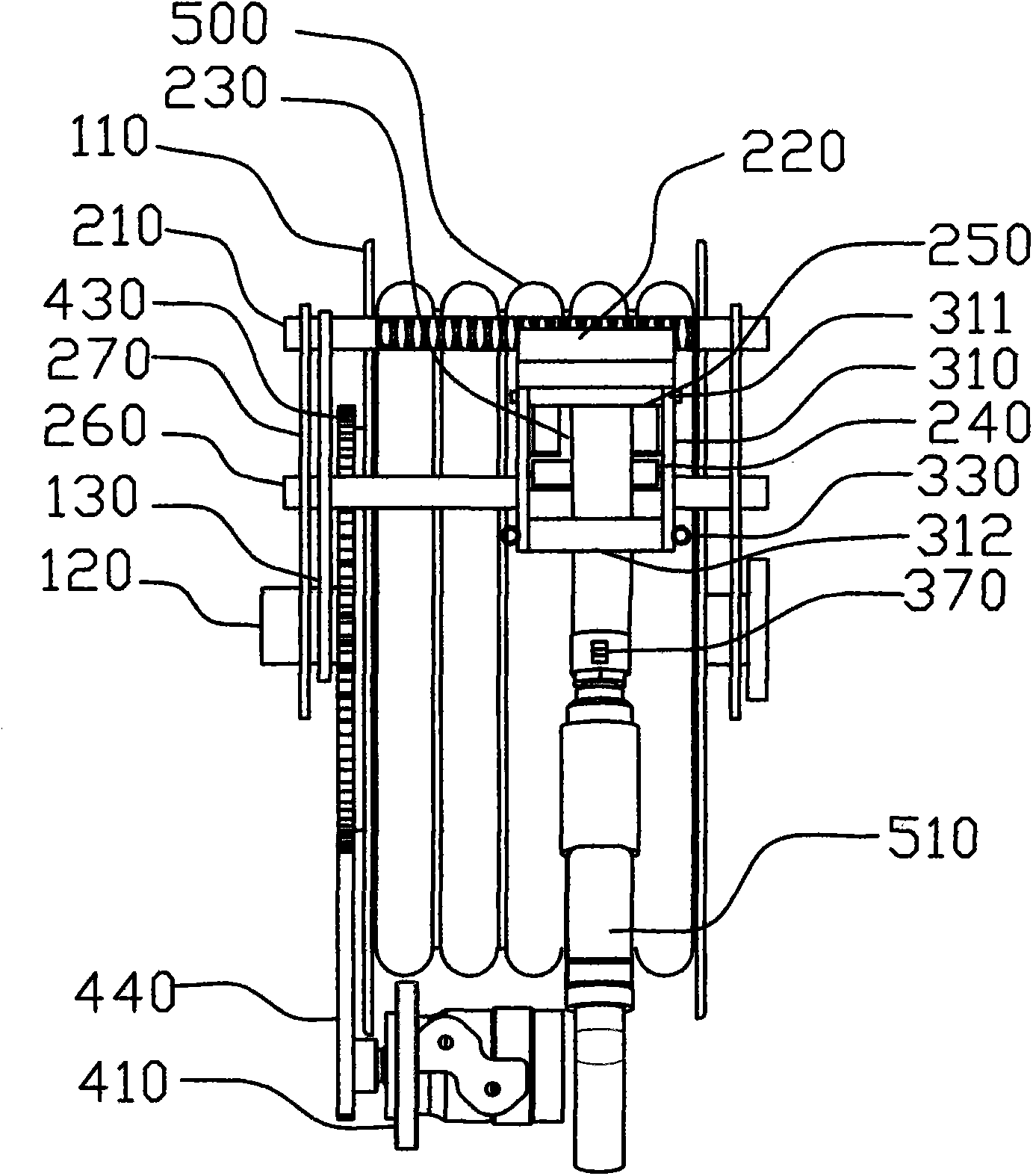

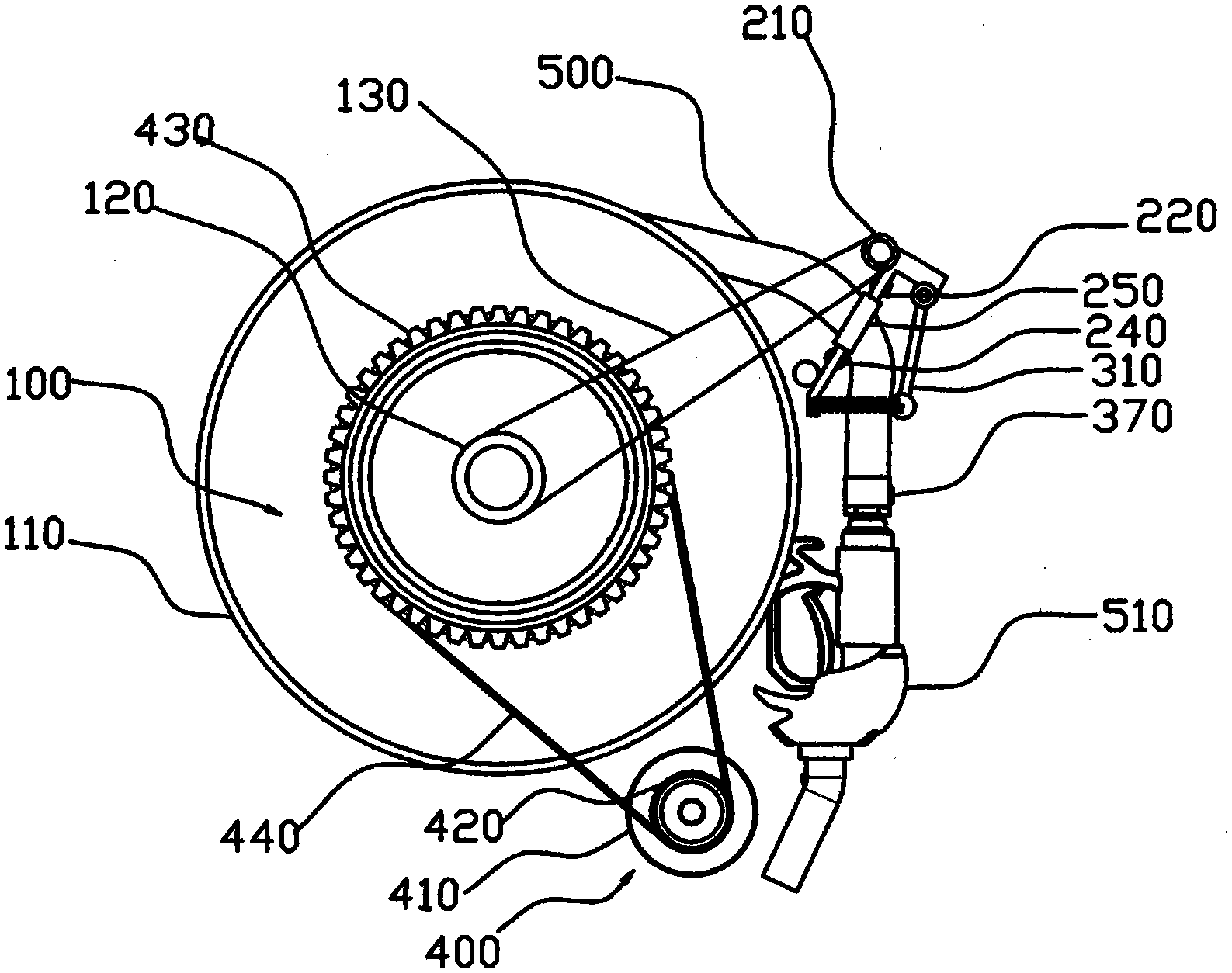

[0042] figure 1is a schematic side view of a reel device according to an embodiment of the present invention. The reel device generally includes: a reel frame 100 , a guide assembly 200 installed on the reel frame 100 , and a damping device 300 installed on the guide assembly 200 . Wherein, the reel frame 100 includes: a central shaft 120 for winding cables and pipes, and baffles 110 respectively arranged at two ends of the central shaft 120 and perpendicular to the central shaft 120 . The central shaft 120 can take the installation point with the baffle plate 110 as a support point, and realize the clockwise and counterclockwise rotation under the corresponding automatic or manual drive, so that the cables and pipes wound on the surface of the central shaft can be retracted and released. . The guide assembly 200 includes: a bidirectional screw rod 210 and a polished rod 260 respectively installed on the reel frame 100 and spaced parallel to the central axis 120, and respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com