Landscape lake water supplementing and purifying process

A purification process and lake technology, which is applied in the field of landscape lake water replenishment and purification process, can solve the problems that water cannot be replenished in landscape lakes, increase the cost of filtration devices, increase the cost of filtration time, etc., reduce the cost of replacement, save cleaning time, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

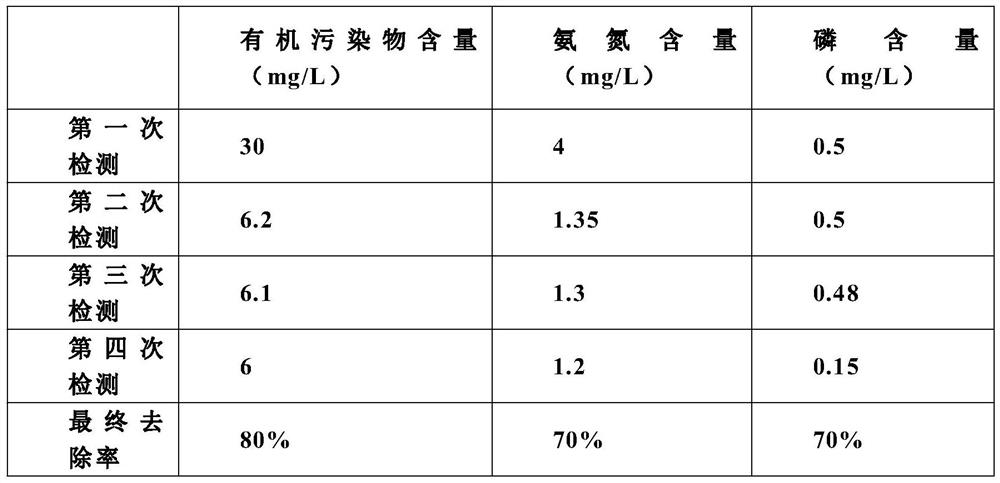

[0036] (1) Sewage passes through the flocculation tank to complete the separation of sewage and impurities through adsorption. The organic pollutants, ammonia nitrogen, and phosphorus content in the sewage treated by the flocculation tank are detected for the first time. The test data are shown in Table 1.

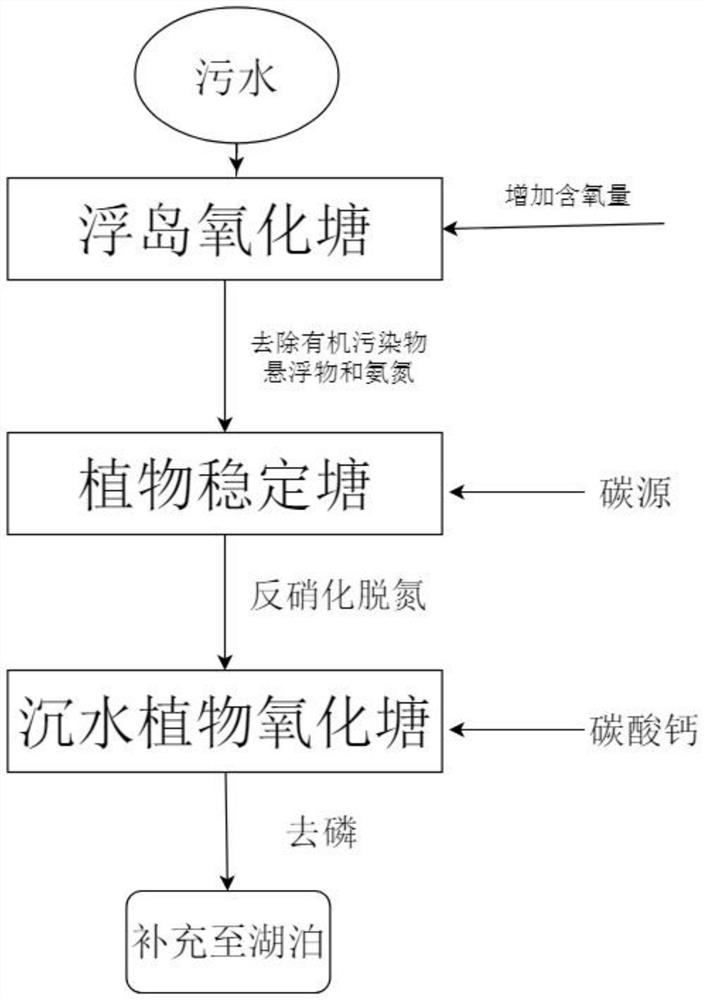

[0037] (2) The sewage enters the floating island oxidation pond, and the blower room aerates the floating island oxidation pond. The aeration time is 18 hours, and the influent flow of the floating island oxidation pond is 15000m 3 / d, the maximum water depth is 2.5 meters, and the water area is 26000m 2 , volume is 65000m 3 , the slope slope is 1:6, the operating water level elevation is 47m, the water level elevation at the bottom of the pond is 44.5m, the hydraulic retention time in the floating island oxidation pond is 4d, and the hydraulic load is 0.5m 3 / m 2 d. The total vegetation coverage of the floating island oxidation pond is 70%, and the oxygen content is 3mg...

Embodiment 2

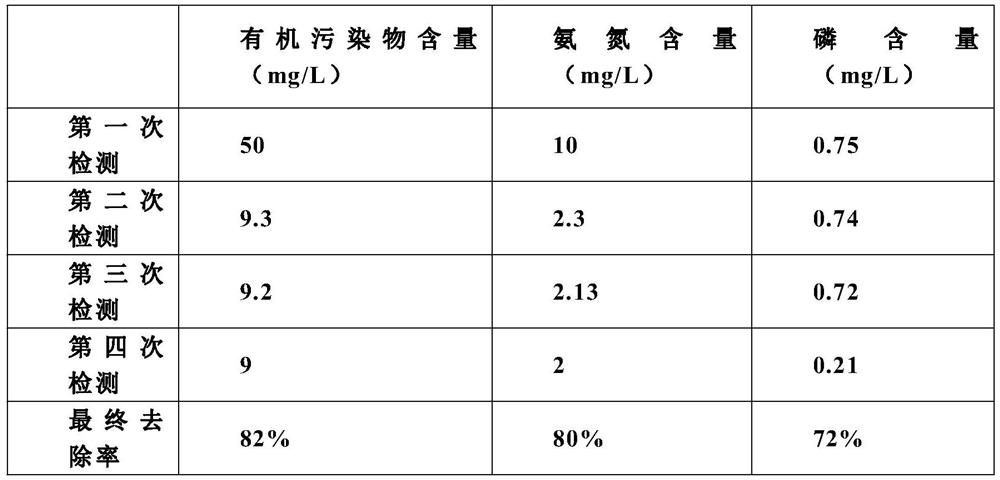

[0044] (1) Sewage passes through the flocculation tank to complete the separation of sewage and impurities through adsorption. The organic pollutants, ammonia nitrogen, and phosphorus content in the sewage treated by the flocculation tank are detected for the first time. The test data are shown in Table 2.

[0045] (2) The sewage enters the floating island oxidation pond, and the blower room aerates the floating island oxidation pond. The aeration time is 21 hours, and the influent flow of the floating island oxidation pond is 15000m 3 / d, the maximum water depth is 2.5 meters, and the water area is 26000m 2 , volume is 65000m 3 , the slope slope is 1:6, the operating water level elevation is 47m, the water level elevation at the bottom of the pond is 44.5m, the hydraulic retention time in the floating island oxidation pond is 5d, and the hydraulic load is 0.75m 3 / m 2 d. The total vegetation coverage of the floating island oxidation pond is 85%, and the oxygen content is 3....

Embodiment 3

[0052] (1) Sewage passes through the flocculation tank to complete the separation of sewage and impurities through adsorption. The organic pollutants, ammonia nitrogen, and phosphorus content in the sewage treated by the flocculation tank are detected for the first time. The test data are shown in Table 3.

[0053] (2) The sewage enters the floating island oxidation pond, and the blower room aerates the floating island oxidation pond. The aeration time is 24 hours, and the influent flow of the floating island oxidation pond is 15000m 3 / d, the maximum water depth is 2.5 meters, and the water area is 26000m 2 , volume is 65000m 3 , the slope slope is 1:6, the operating water level elevation is 47m, the water level elevation at the bottom of the pond is 44.5m, the hydraulic retention time in the floating island oxidation pond is 6d, and the hydraulic load is 1m 3 / m 2 d. The total vegetation coverage of the floating island oxidation pond is 80%, and the oxygen content is 4mg / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com