Structural dynamics design method of rotor of aerial engine

A technology of aero-engine and rotor structure, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve problems such as specific methods and steps of rotor structure dynamics that have not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

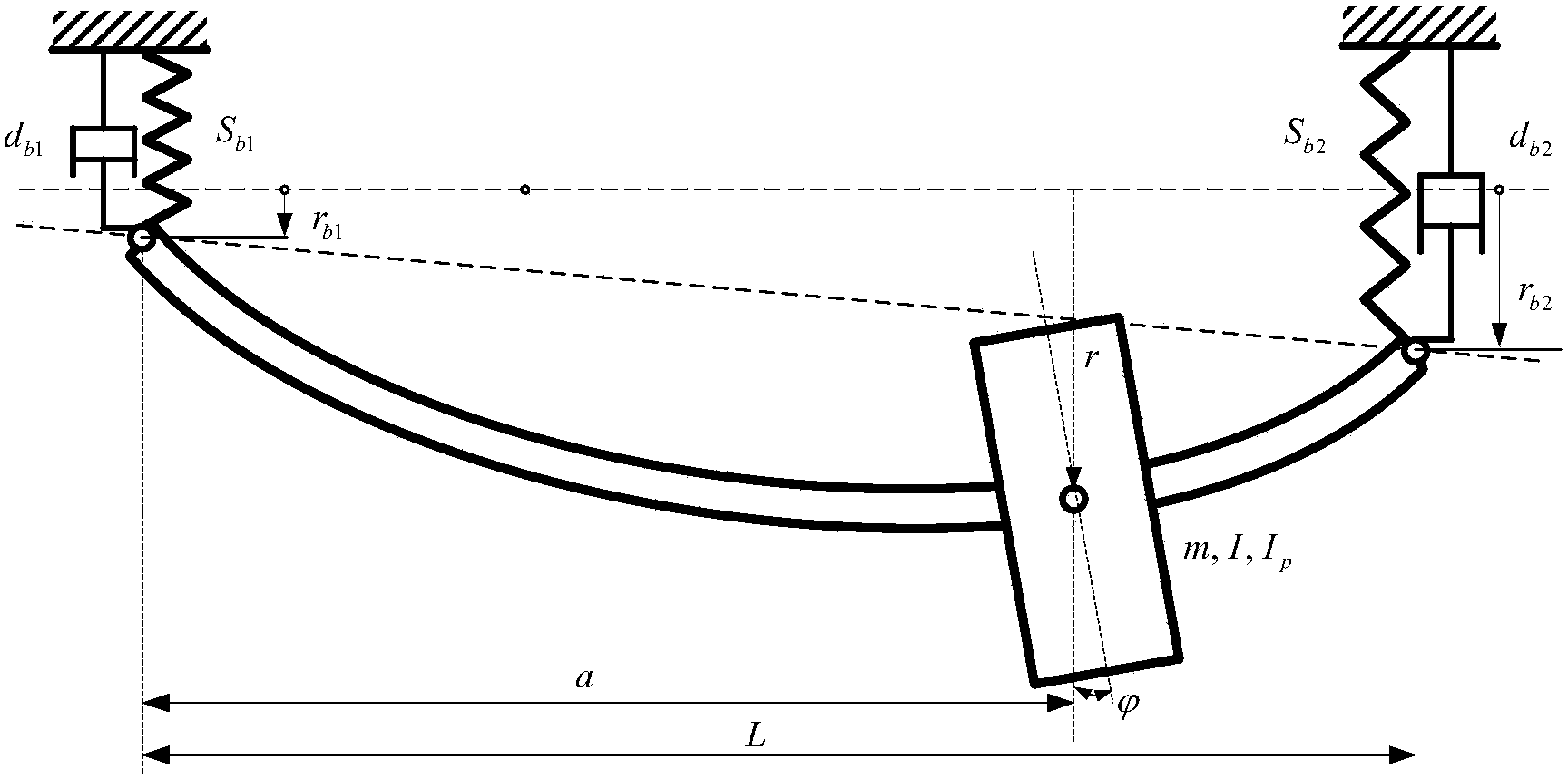

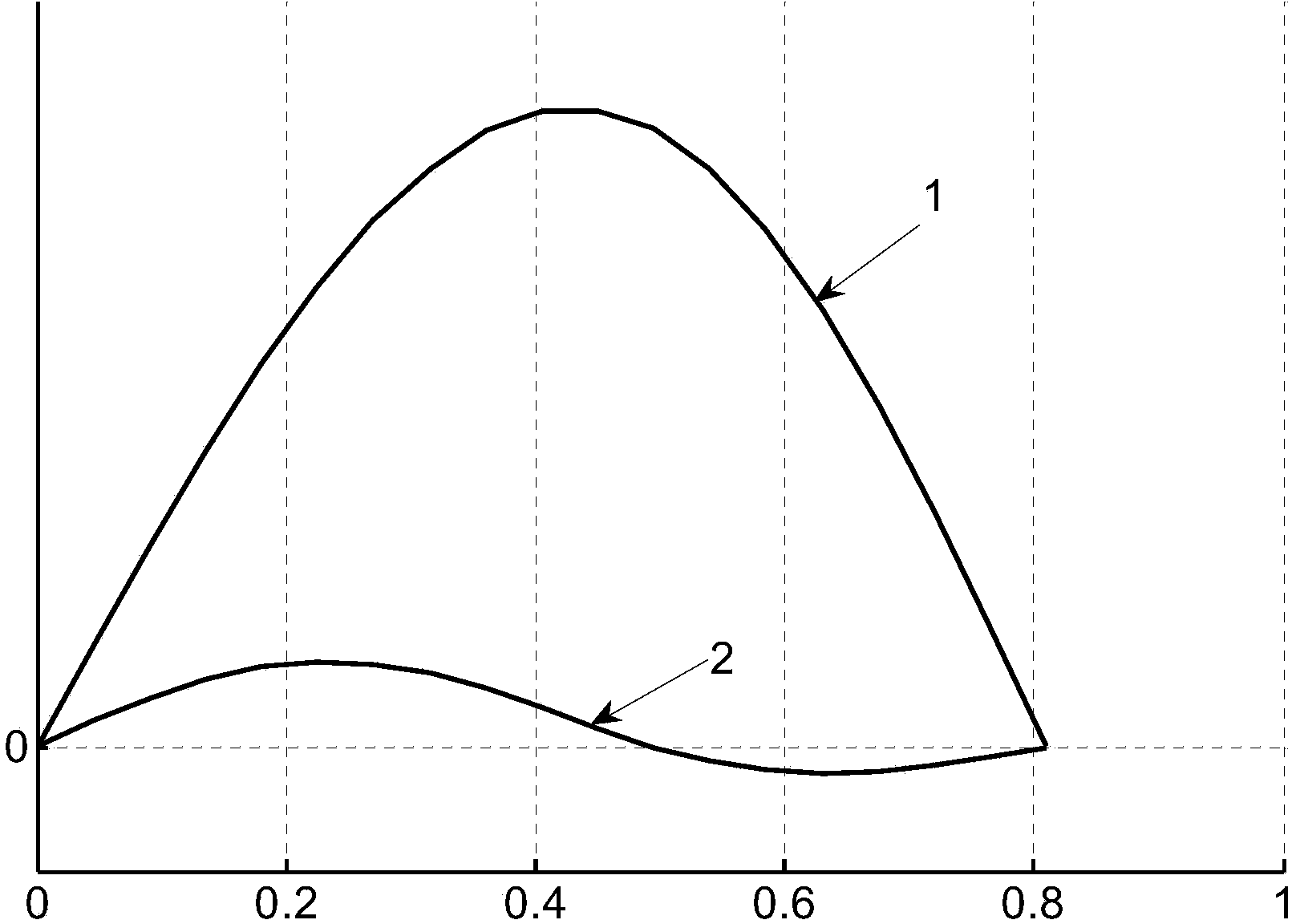

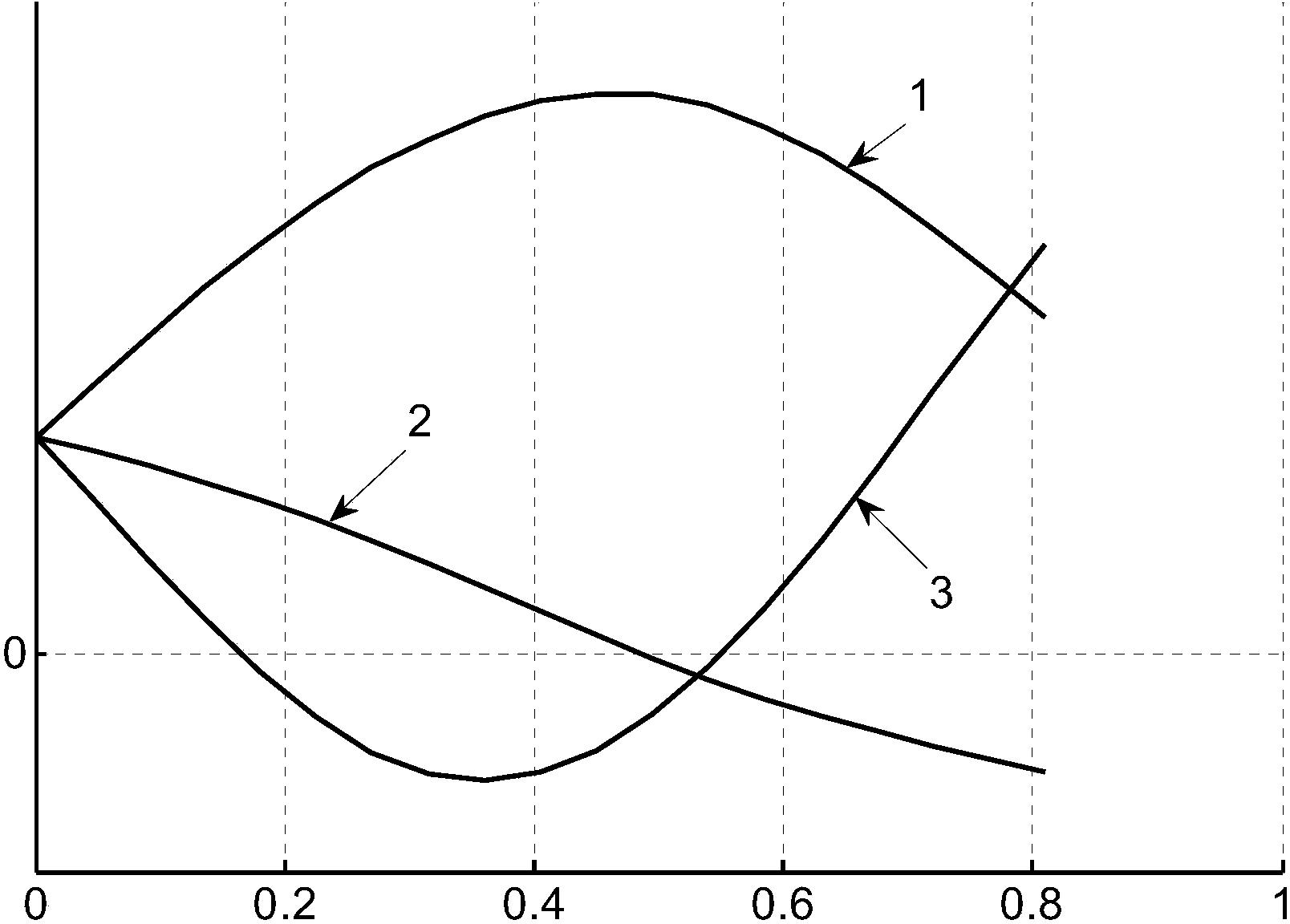

[0063] In order to adapt to the design requirements of the rotor dynamics of the aero-engine with high thrust ratio performance, this embodiment proposes a set of rotor dynamics design methods throughout the design of the entire engine rotor.

[0064] For the aeroengine with high thrust ratio performance, this embodiment proposes a definition of the rotor mode, that is, the thermal mode. The thermal mode refers to the mode corresponding to the critical speed of one or more rotors when the running speed of the engine frequently passes through the critical speed of one or more rotors during the operation of the engine.

[0065] The reason why it is defined as thermal mode is that the rotor frequently crosses the critical speed during the operation of the engine, and the critical speed may even become the working speed; The rotational speed varies in a wide range, so it is difficult to guarantee the rotational speed margin during design; the third is because in the thermal mode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com