Double-rotor double-stage compressor and refrigerating/heating system thereof

A two-stage compressor and two-stage compression technology, applied in compressors, compressors with reversible cycles, refrigerators, etc., can solve the problems of reduced high-pressure stage compression efficiency, complex lower bearing structure, and increased suction resistance. , to improve the compressor capacity, the lower bearing structure is simple, and the suction resistance is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

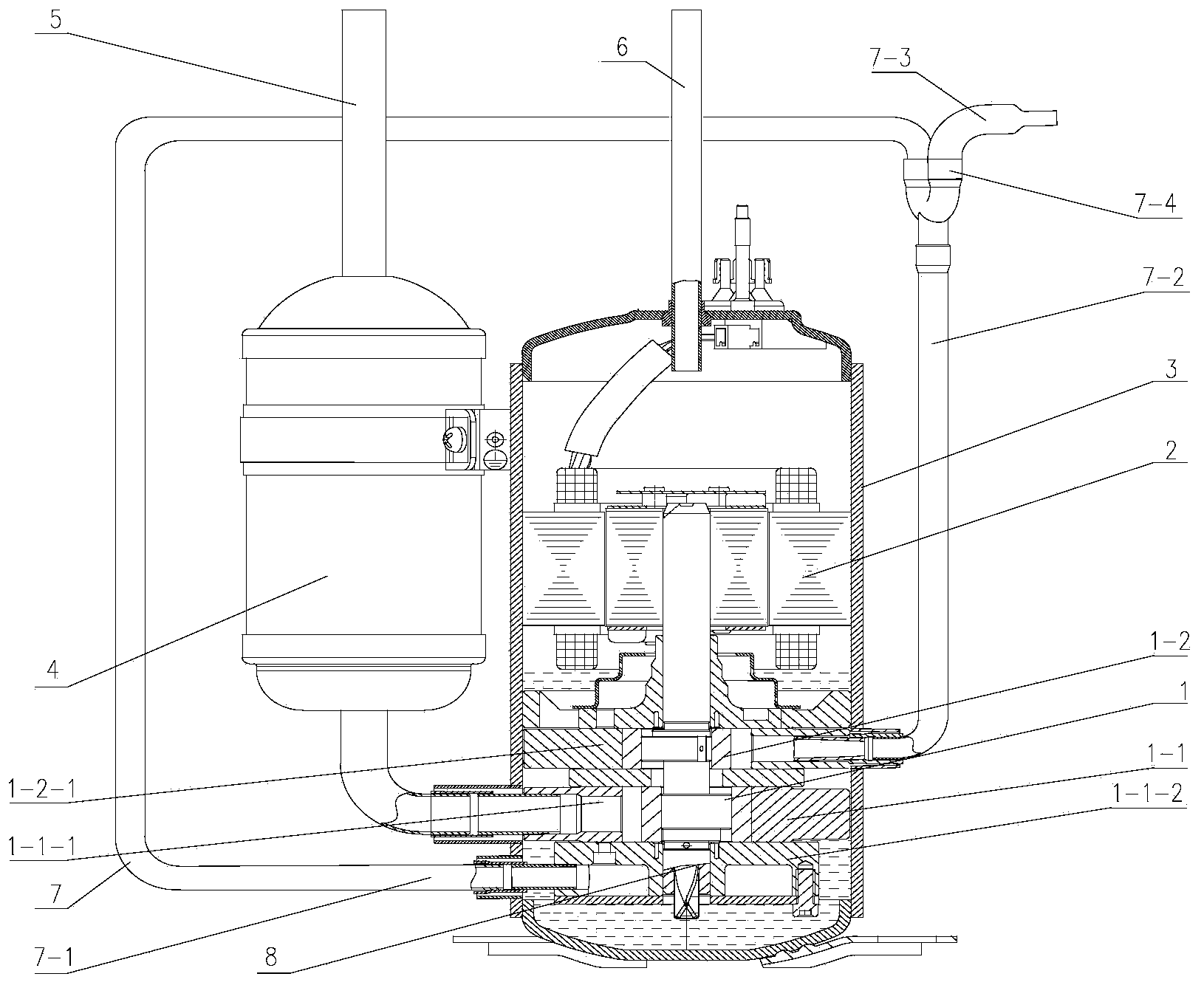

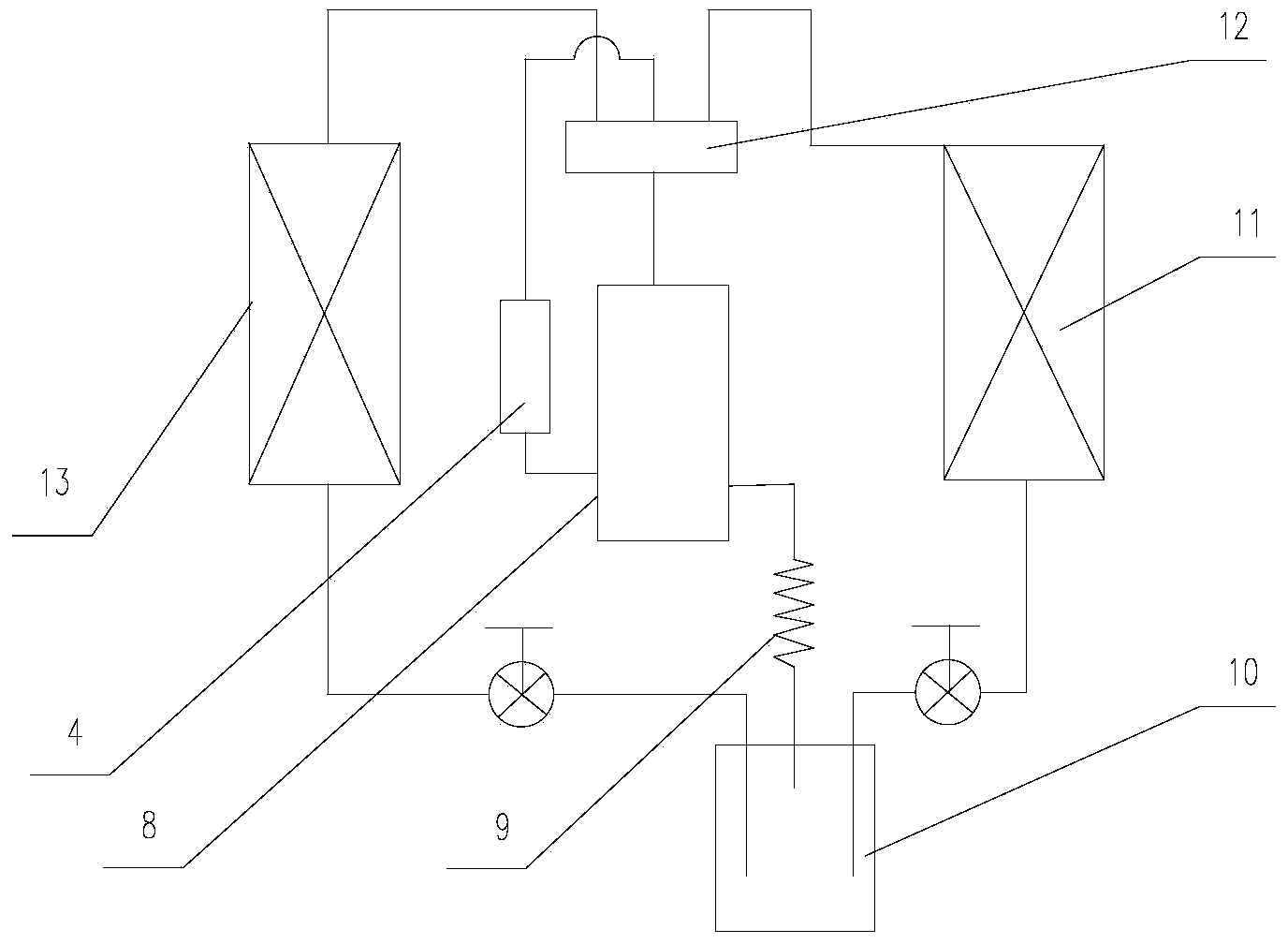

[0014] In order to overcome the shortcomings of the prior art, the present invention provides a dual-rotor two-stage compressor 8 with intermediate enthalpy increase, including a two-stage compression mechanism 1 (composed of a low-pressure stage rotor compression mechanism 1-1 and a high-pressure stage rotor compression mechanism 1-2 Composition), driving motor 2 for driving the two-stage compression mechanism 1, housing 3, liquid reservoir 4, suction pipe 5 and external connecting pipe 7; the two-stage compression mechanism 1 and the driving motor 2 are arranged in the housing 3, and the housing The top of the body 3 is provided with an exhaust pipe 6 . The external connection pipe 7 is formed by connecting a low-pressure exhaust pipe 7-1, a high-pressure suction pipe 7-2, and an injection pipe 7-3 through a three-way pipe 7-4. The inlet of the liquid reservoir 4 is connected to the suction pipe 5, and the outlet is connected to the low-pressure stage cylinder 1-1-1 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com