Directly buried prefabricated heat-insulation high-temperature hot water tube and production method thereof

A hot water pipe, high temperature technology, applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, to avoid repeated pipeline construction, limited cost increase, and economical satisfaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

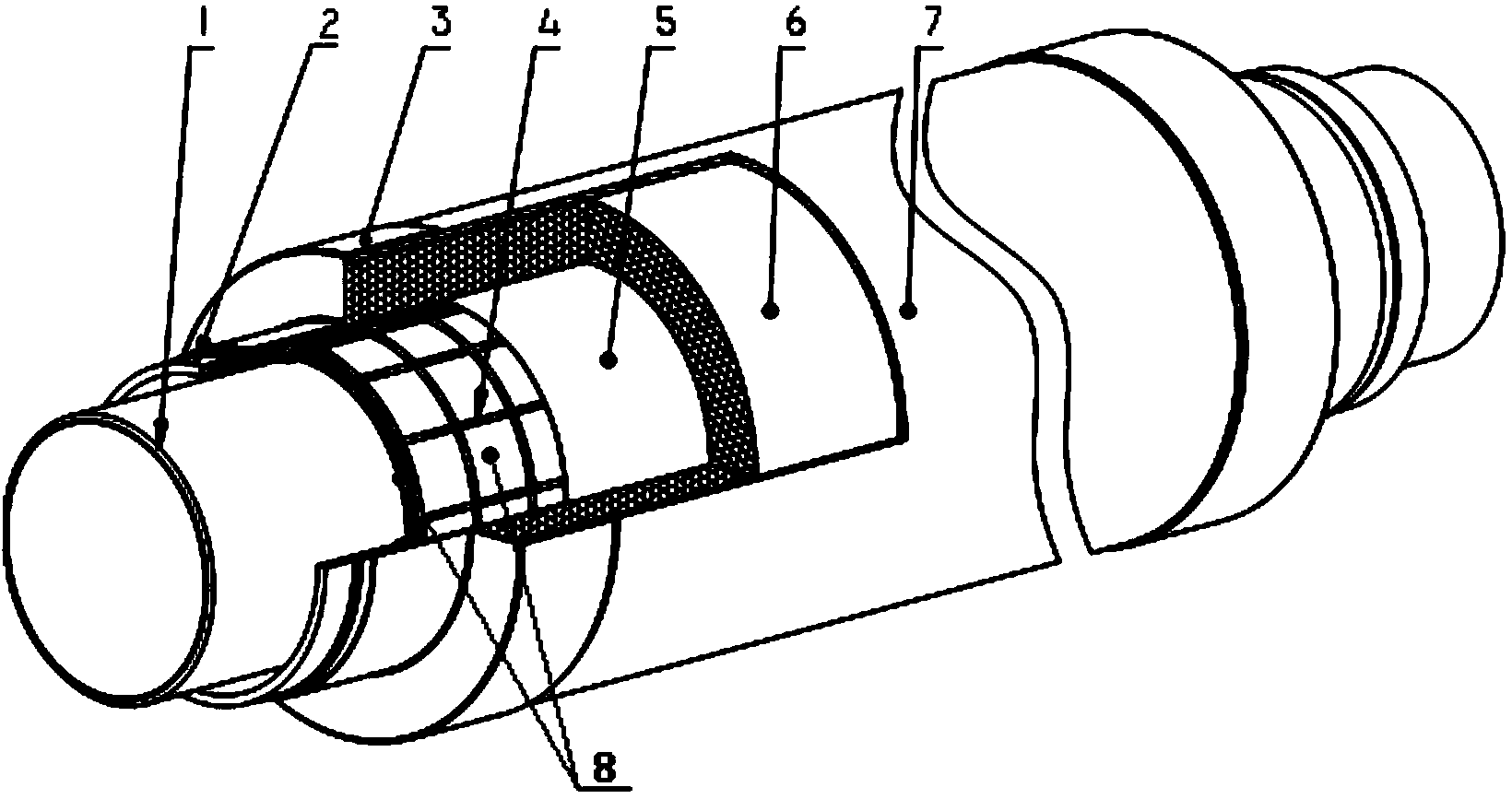

[0022] See figure 1 , is a structural schematic diagram of an embodiment of a direct-buried prefabricated heat-insulating high-temperature hot water pipe according to the present invention, including a working steel pipe 1, an insulating layer 6 and an outer protective pipe 7, an insulating layer 6 is arranged between the working steel pipe 1 and the outer protective pipe 7, and the outer The cross-sections at both ends of the protection pipe 7 and the insulation layer 6 are wrapped with heat-shrinkable sealing end caps 3, and between the working steel pipe 1 and the insulation layer 6, a galvanized steel wire mesh layer 4 and a smooth aluminum plate 5 are sequentially arranged between the working steel pipe 1 and the insulation layer 6. The two ends of the steel wire mesh layer 4 are respectively provided with guiding and positioning rings 2. During operation, when the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com