Method for measuring gas permeation coefficient of compact rock under three dimensional stress condition

A technology of three-dimensional stress and gas permeation, which is applied in the directions of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of complex on-site sample operation, long test period, and huge cost, and achieve test results. The effect of short process, overcoming large measurement error, and simple and convenient test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

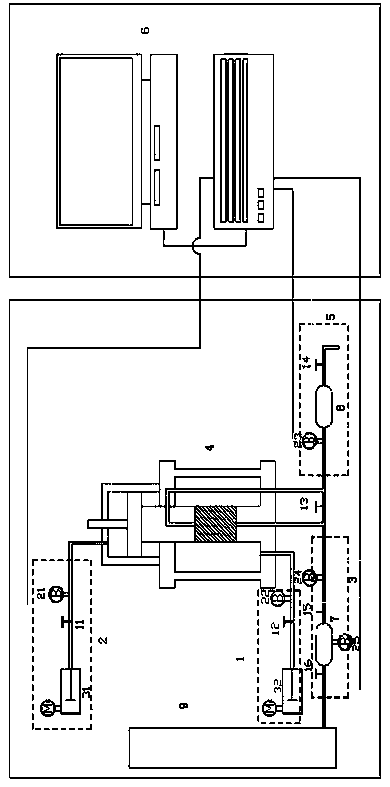

Method used

Image

Examples

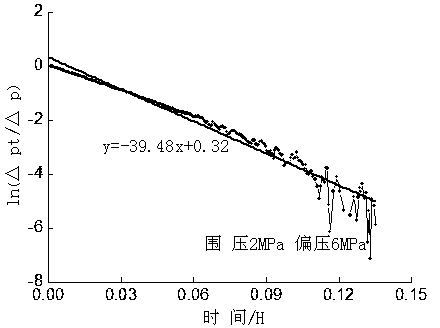

Embodiment 1

[0042] 1) This example is to measure the permeability coefficient of tight sandstone under the action of each stress path. First, a test rock sample with a diameter of 50 mm and a height of 100 mm is made according to the standard, and the rock sample is dried in an oven for 24 hours and then loaded into a triaxial pressure chamber;

[0043] 2) Apply the confining pressure to the predetermined value of 20MPa, and keep the confining pressure unchanged;

[0044] 3) After the confining pressure is stable, apply a bias voltage to 60MPa and keep the bias voltage unchanged;

[0045] 4) After the bias voltage is stabilized, close the gas outlet switch and increase the gas pressure at the gas inlet to 10MPa. Due to the pressure difference, the gas gradually flows through the rock sample to the gas discharge system, and the pressure at both ends of the sample is gradually balanced to 5MPa;

[0046] 5) When the pressure value of the air inlet and the air outlet are equal, the pressure o...

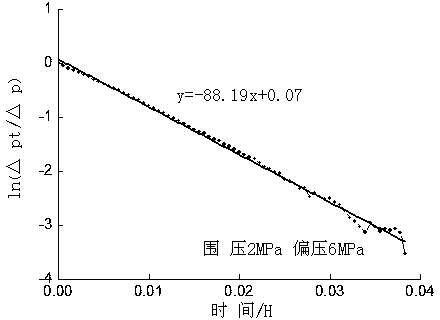

Embodiment 2

[0050] 1) This example is to measure the permeability coefficient of granite gneiss under each stress path. Firstly, a test rock sample with a diameter of 50 mm and a height of 100 mm is made according to the standard. The rock sample is dried in an oven for 24 hours and then loaded into a triaxial pressure chamber. middle;

[0051] 2) Apply the confining pressure to the predetermined value of 20MPa, and keep the confining pressure unchanged;

[0052] 3) After the confining pressure is stable, apply a bias voltage to 60MPa and keep the bias voltage unchanged;

[0053] 4) After the bias voltage is stabilized, close the gas outlet switch and increase the gas pressure at the gas inlet to 10MPa. Due to the pressure difference, the gas gradually flows through the rock sample to the gas discharge system, and the pressure at both ends of the sample is gradually balanced to 5MPa;

[0054] 5) When the pressure value of the air inlet and the air outlet are equal, the pressure of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com