Three-warehouse coordinated management cigarette logistics system

A logistics system and collaborative management technology, applied in the field of logistics systems, can solve the problems of poor continuity of logistics process, failure to achieve logistics efficiency, waste of logistics costs, etc., achieve efficient data exchange and logistics operation, and achieve operational efficiency and savings. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical solution and characteristics of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. Here, the following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

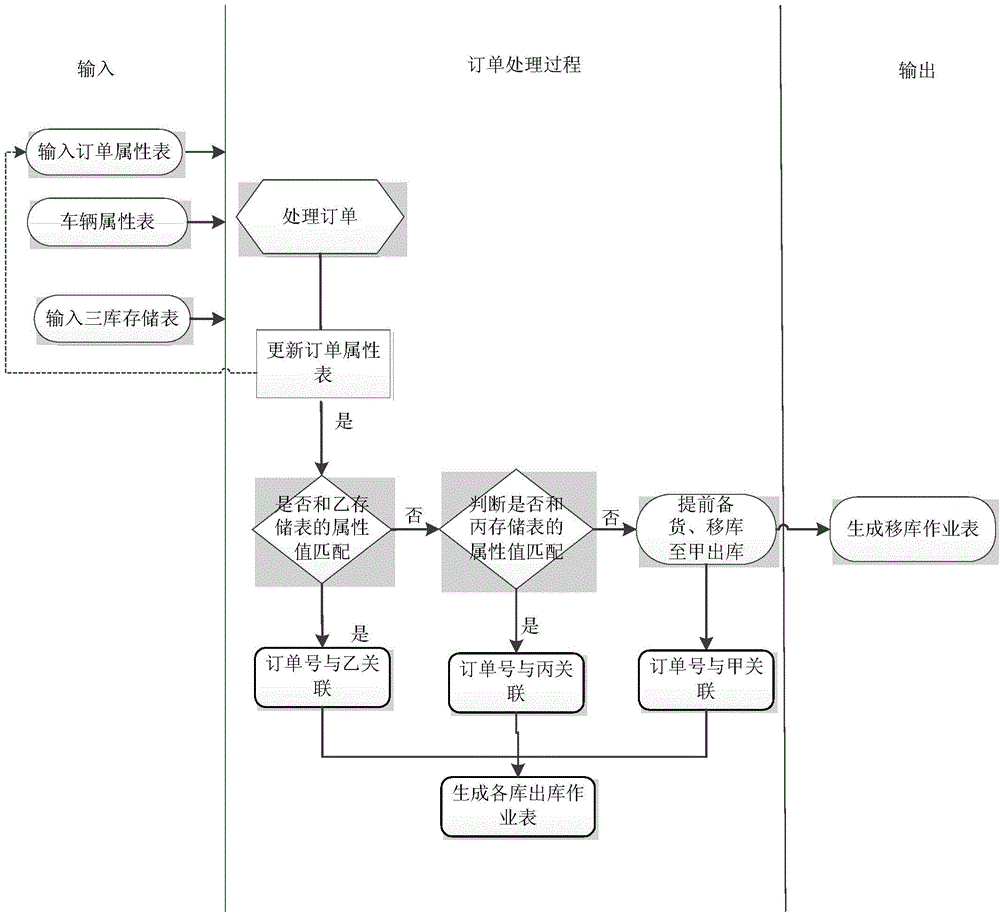

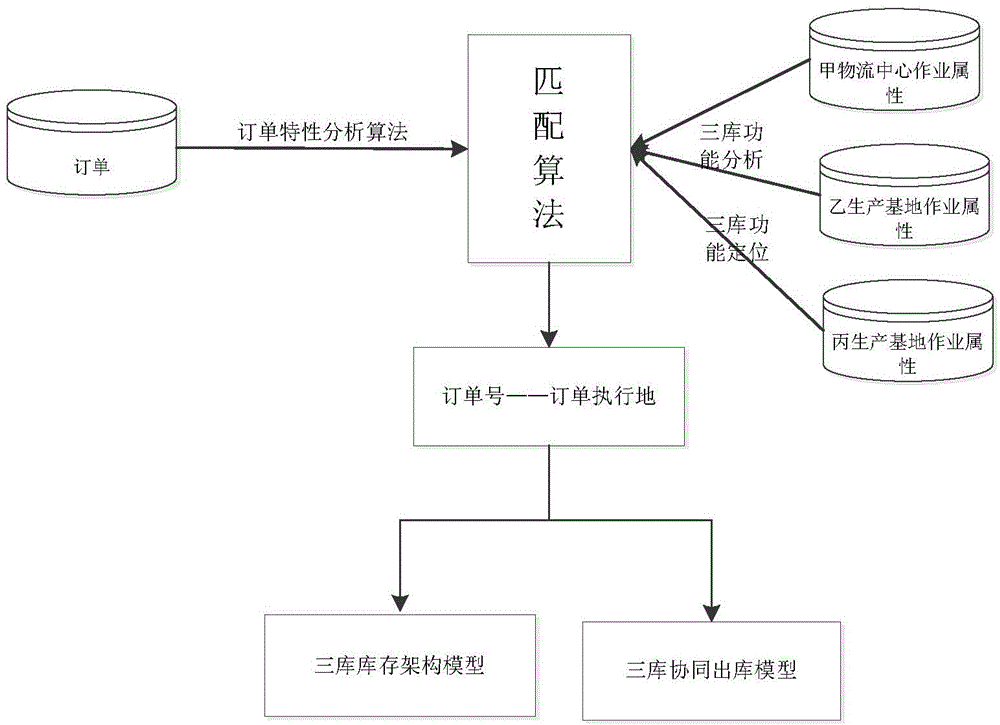

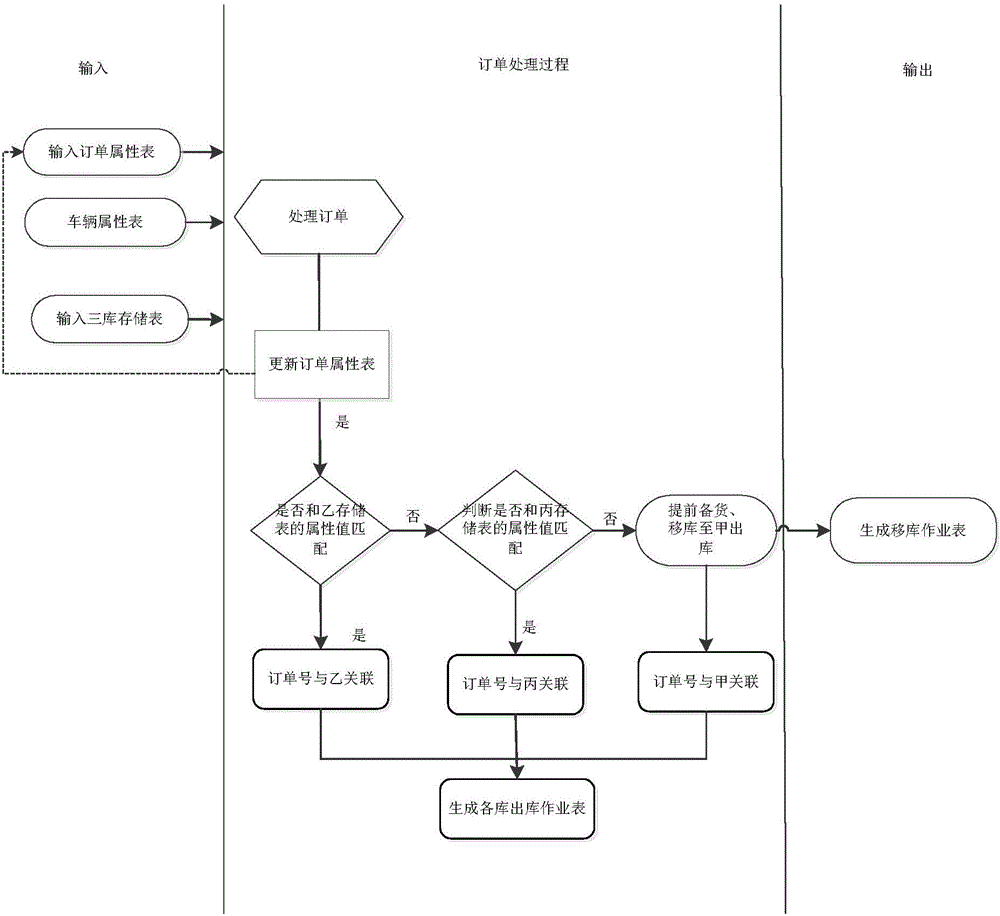

[0039] Such as figure 1 As shown, the multi-warehouse collaborative inventory structure is based on the analysis of an enterprise's order characteristics and status quo, and on the basis of the product specification level determination algorithm model and the order fluctuation algorithm model, a schematic diagram of the optimal matching structure of the multi-warehouse collaborative strategy is established, including : The relationship among order, inventory structure and delivery structure.

[0040] Specifically, the operation attribute of A logistics center, the operation attribute of B production base, and the operation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com