Whole seed melon powder and preparation method thereof

A technology of seed melon and melon body, which is applied in the field of fruit and vegetable powder processing and preparation, and the preparation technology of whole seed melon powder, which can solve the problems of unused melon pulp and melon skin, low utilization efficiency of melon seeds, and low utilization rate of melon seeds, so as to avoid heat Instability, short heating time and low material temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: the preparation of whole powder of seed melon

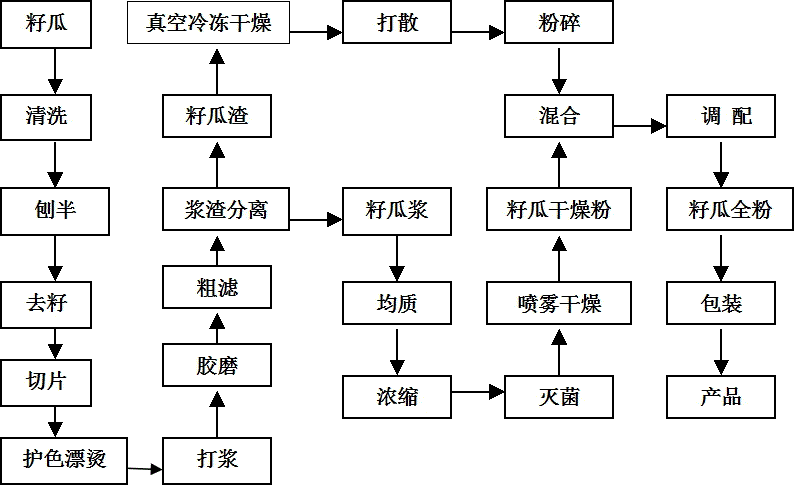

[0045] See attached figure 1 , the concrete preparation method of whole powder of seed melon is as follows:

[0046] (1) Choose fresh, pest-free seed melons, soak them in clean water, and then wash the melon body with water to remove residual pesticides and sediment adhering to the melon body. Cut the seed melons in half, remove the seeds, and cut them into 0.5-1.0cm pieces. Thick slices.

[0047] (2) Add 0.1% to 0.5% ascorbic acid or 0.1% to 0.5% citric acid solution or ascorbic acid and citric acid to the cut melon slices in step (1) and keep for 5 to 15 minutes to protect the color.

[0048] (3) Beat the color-protected seed melon in the above step (2) into a coarse pulp with a beater, then immediately put it into a colloid mill to grind it finely, adjust the gap between the grinding discs to 20-50um, and grind the colloid once or more.

[0049] (4) Filter the slurry that has passed through the coll...

Embodiment 2

[0059] Embodiment two: the preparation of whole powder of seed melon

[0060] Select seed melons, soak and wash them in clean water, cut them in half, remove seeds, and cut them into thick slices of about 0.5 cm; add 0.1% to 0.5% ascorbic acid solution and keep for 5 minutes to protect the color; beat the color-protected seed melons with a beater Immediately put into the colloid mill to grind the coarse slurry, adjust the gap between the grinding discs to 20um, and filter the slurry after the colloid mill with an 80-mesh pulp and slag separator to separate the crude fiber and other substances from the seed melon juice; vacuum freeze-dry the coarse slag , the first stage is the pre-freezing process, the pre-freezing temperature is -15°C, the pre-freezing time is 2 hours, and the material filling thickness is 5mm; the second stage is the vacuum drying stage, and the working pressure of the drying chamber is set, that is, the vacuum degree is 20 Pa, the sublimation heating temp...

Embodiment 3

[0061] Embodiment three: the preparation of whole powder of seed melon

[0062] Select seed melons, soak and wash them in clean water, cut them in half, remove seeds, and cut them into thick slices of about 1.0 cm; add 0.1% to 0.5% citric acid solution and keep for 15 minutes to protect the color; use a beater to preserve the color of the seed melons Immediately put it into a colloid mill to grind it into a coarse pulp, adjust the gap between the grinding discs to 50um, and filter the pulp after the colloid mill with an 80-mesh slurry separator to separate the crude fiber and other substances from the seed melon juice; vacuum freeze the coarse residue Drying, the first stage is the pre-freezing process, the pre-freezing temperature is -35 ℃, the pre-freezing time is 6h, and the material filling thickness is 20mm; the second stage is the vacuum drying stage, and the working pressure of the drying chamber is set, that is, the vacuum degree is 120 Pa, the sublimation heating te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com