High-precision micro-injection pump and application thereof

A micro-injection pump, high-precision technology, applied in the direction of pressure infusion, flow monitors, and devices introduced into the body, can solve the problems of poor stability, poor adaptability of micro-injection pumps, inaccurate flow rate, etc., to achieve good stability, Accurate effect of drug flow rate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

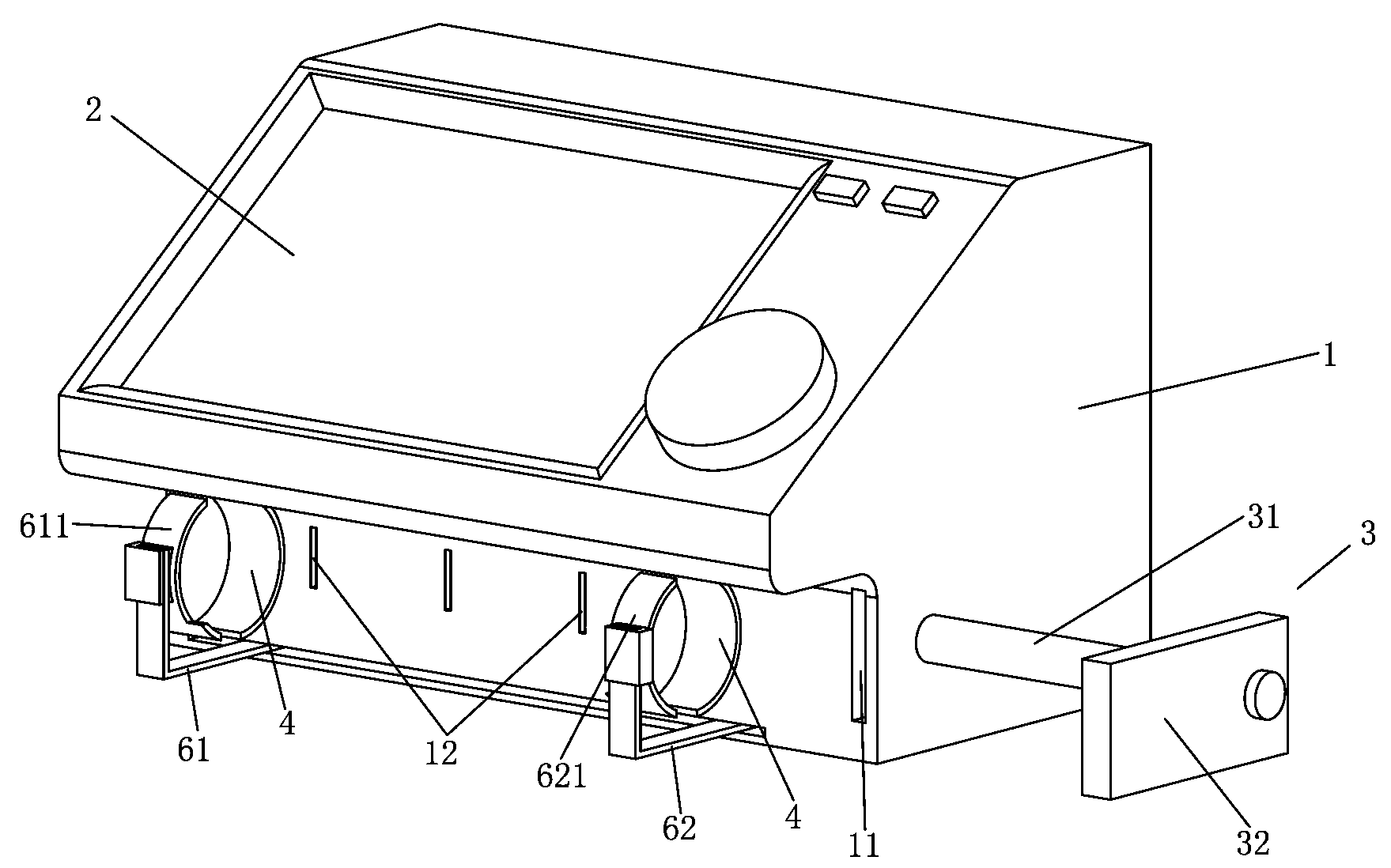

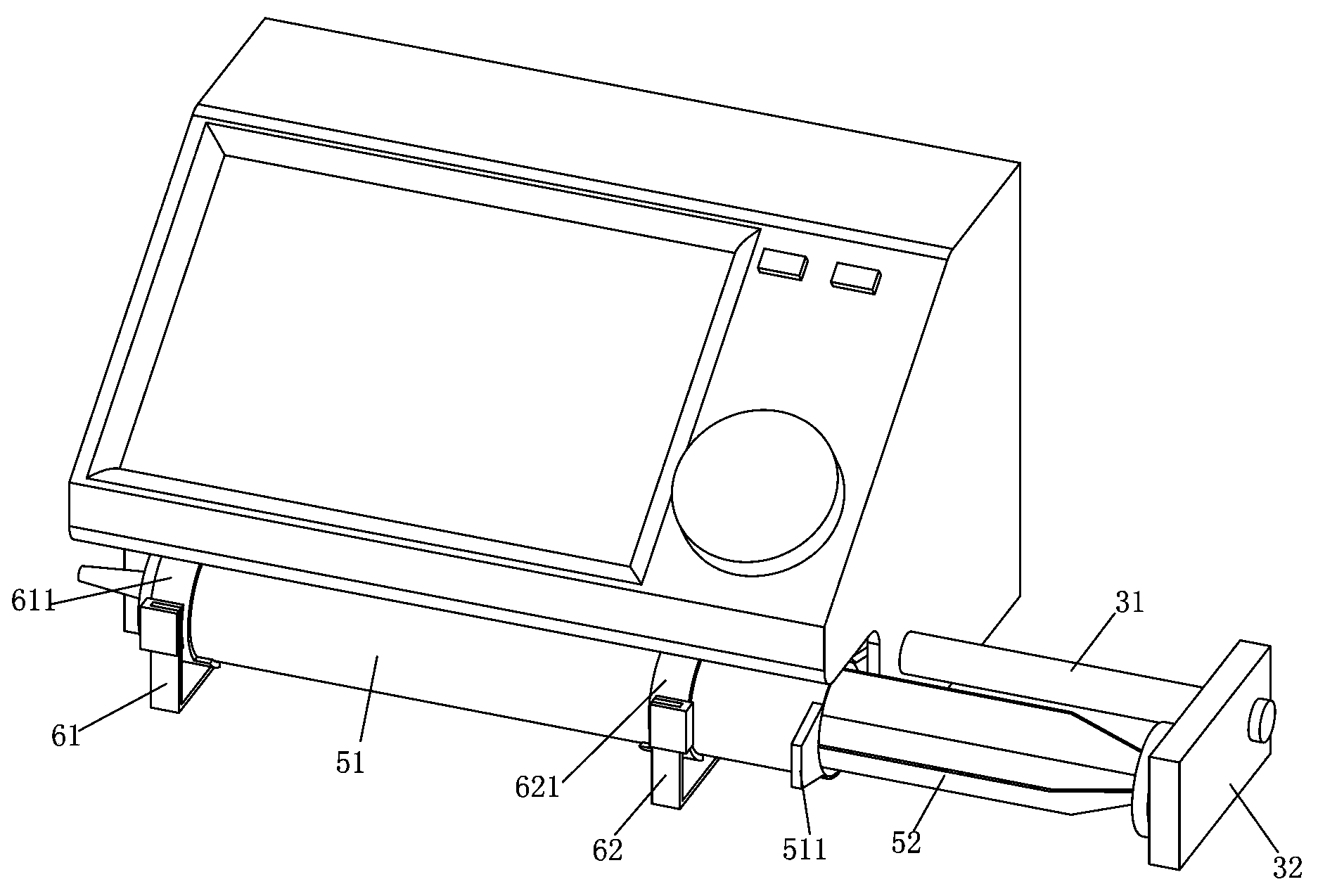

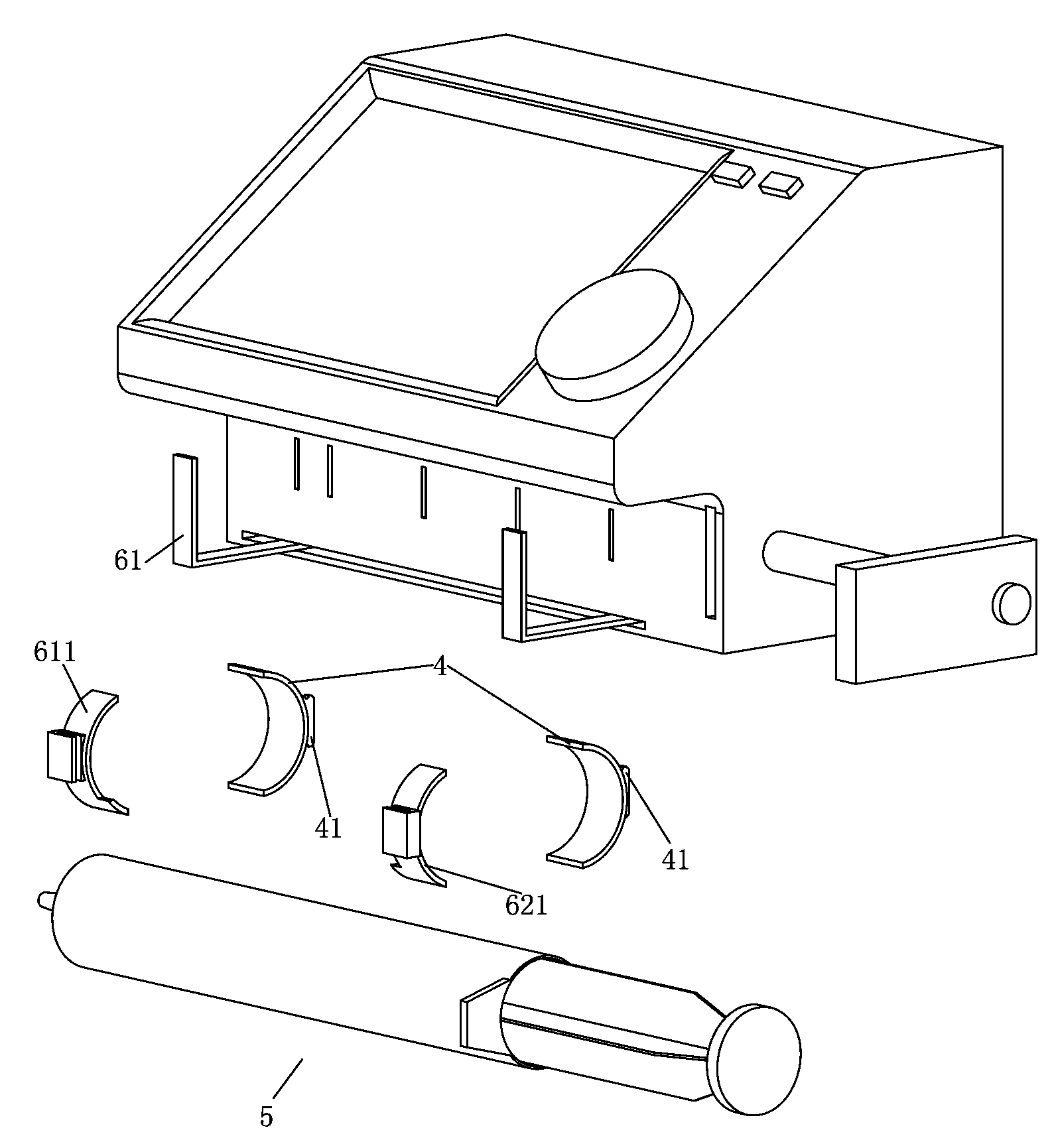

[0026] refer to Figure 1 to Figure 5 As shown in , the present invention includes: a casing 1, a display input module 2, a stepping motor propulsion mechanism 3 and a main control module; the display input module 2 is arranged on the casing 1, and the display input module 2 can be a touch screen , it can also be a combination of a display screen and an input button, and the stepping motor propulsion mechanism 3 and the main control module are arranged in the housing 1; connect.

[0027] A syringe handle slot 11 is provided on the front side wall of the housing 1 . During use, the syringe 5 is placed horizontally and laterally, and one side handle 511 of the syringe barrel 51 is inserted into the syringe handle slot 11 . The front side wall of the housing 1 is also provided with two syringe brackets 4 for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com