A Continuous Activation Separator with Raney Nickel Catalyst

A catalyst and separator technology, applied in the field of Raney nickel catalyst continuous activation separator, can solve the problems of insufficient reaction, unstable reaction temperature, incomplete material mixing, etc., and achieve the effect of sufficient reaction and accelerated effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

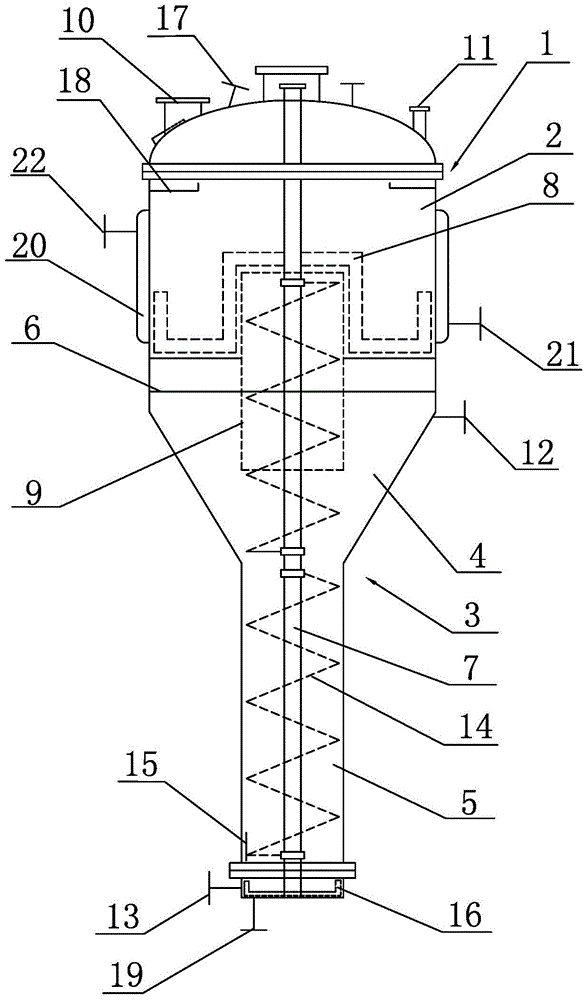

[0027] A kind of Raney nickel catalyst continuous activation separator of the present invention, as figure 1 As shown, the still body 1 including a sealed arrangement, the still body 1 includes a reaction activation zone 2 and a separation zone 3 located below the reaction activation zone 2, and the separation zone 3 includes an inverted frustum-shaped clarification section 4 and a cylindrical concentration section 5. The large opening at the upper end of the clarification section 4 is connected (and separated) to the bottom of the reaction activation zone 2 through a horizontal partition 6, the small opening at the lower end of the clarification section 4 is connected with the opening at the upper end of the concentration section 5, and the central axis of the kettle body 1 is A rotatable thickener 7 runs through the thickener 7. A rake-type frame stirrer 8 (a frame stirrer 8 with a raised middle part and a downward concave around the middle part) is installed on the thickener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com