A stirring grinding reactor and its method for preparing isocyanate

A reactor and stirring shaft technology, which is applied in the field of preparing isocyanate reactors based on high-temperature salt-forming phosgenation reaction, can solve the problems of long photochemical process time, low salt-forming concentration, and many side reactions, so as to reduce the encapsulation and improve the Mass transfer rate, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

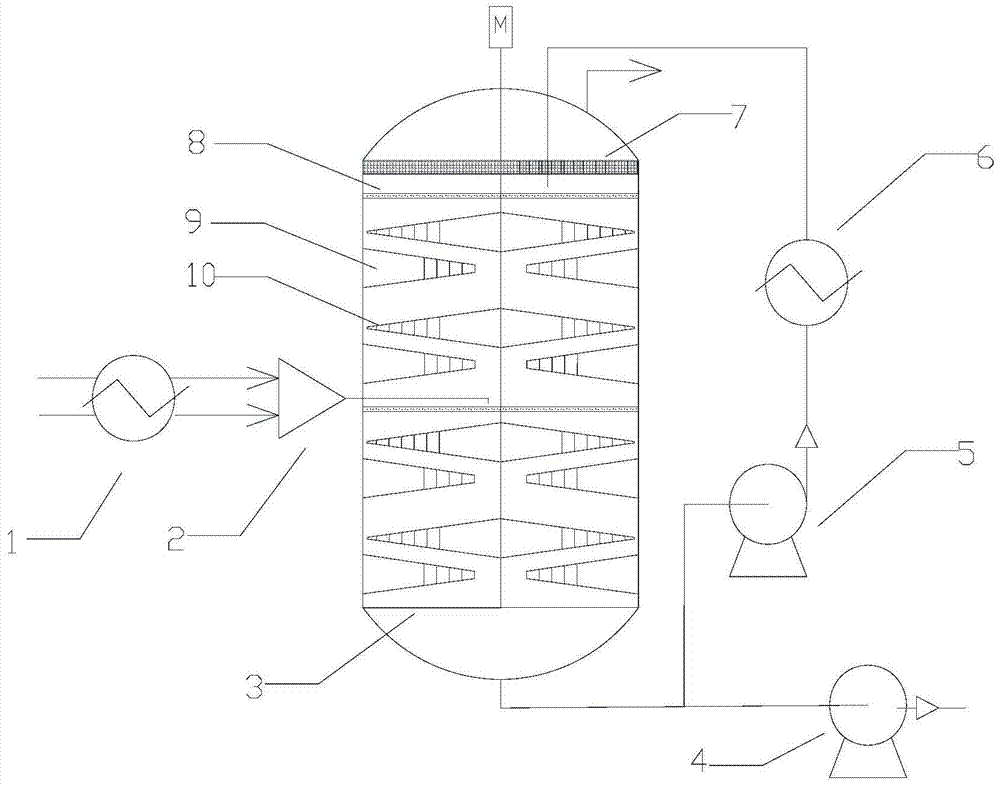

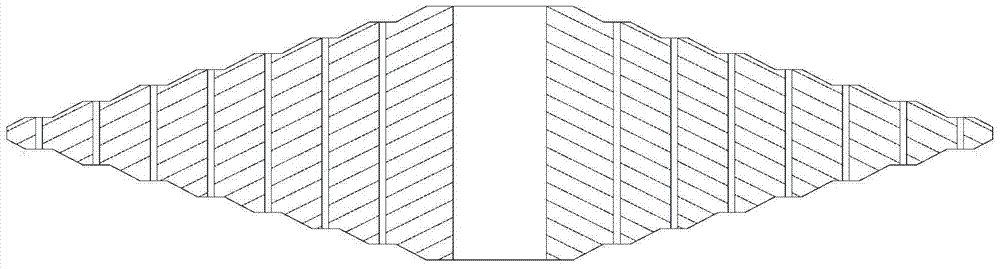

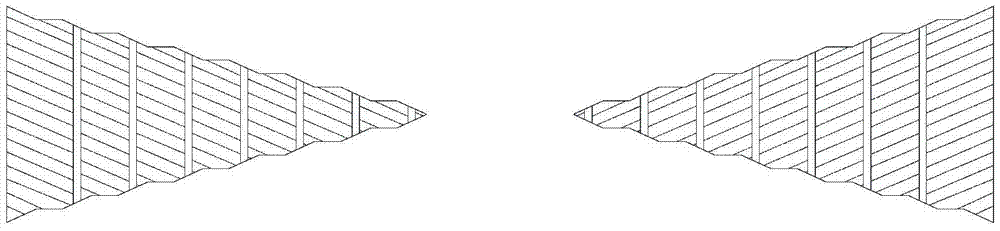

[0062] use attached figure 1 In the process shown, the volume of the salt-forming reactor is 500L, and there are 12 groups of dynamic and static rotating discs in total, 7 groups at the upper part of the feeding port, and 5 groups at the lower part of the feeding port. The lowermost end of each static rotating disc is located below the static rotating disc And the axial distance of the uppermost end of the moving rotating piece of the bell is the same as 50mm, the feed inlet is located above the distributor in the middle of the reactor, the axial distance between the lowermost end of the feed inlet and the uppermost end of the distributor is 150mm, and the lower part of the distributor It is a moving rotating piece, the axial distance between the lowermost end of the distributor and the uppermost end of the moving rotating piece is 80 mm, and the outlet is located at the bottom of the reactor. The moving rotating piece is a solid circular cake-shaped structure with an angle b...

Embodiment 2

[0067] use attached figure 1In the process shown, the volume of the salt-forming reactor is 500L, and there are 7 sets of dynamic and static rotating plates in it, 4 sets at the upper part of the feed inlet, and 3 sets at the lower part of the feeding port. The lowermost end of each static rotating plate is located below the static rotating plate And the axial distance between the uppermost ends of the adjacent movable rotating plates is the same as 200mm, the feed inlet is located above the distributor in the middle of the reactor, the axial distance between the lowermost end of the feed inlet and the uppermost end of the distributor is 80mm, and the lower part of the distributor It is a movable rotating piece, the axial distance between the lowermost end of the distributor and the uppermost end of the moving rotating piece is 50 mm, and the outlet is located at the bottom of the reactor. The moving rotating piece is a solid circular cake-shaped structure with an angle betwe...

Embodiment 3

[0070] use attached figure 1 In the process shown, the volume of the salt-forming reactor is 500L, and there are 10 groups of dynamic and static rotating discs inside, 6 groups at the upper part of the feeding port, and 4 groups at the lower part of the feeding port. The lowermost end of each static rotating disc is located below the static rotating disc And the axial distance between the uppermost ends of the adjacent movable rotating plates is the same as 100mm, the feed inlet is located above the distributor in the middle of the reactor, the axial distance between the lowermost end of the feed inlet and the uppermost end of the distributor is 150mm, and the lower part of the distributor It is a movable rotating piece, the axial distance between the lowermost end of the distributor and the uppermost end of the moving rotating piece is 50 mm, and the outlet is located at the bottom of the reactor. The moving rotating piece is a solid circular cake-shaped structure with an an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com